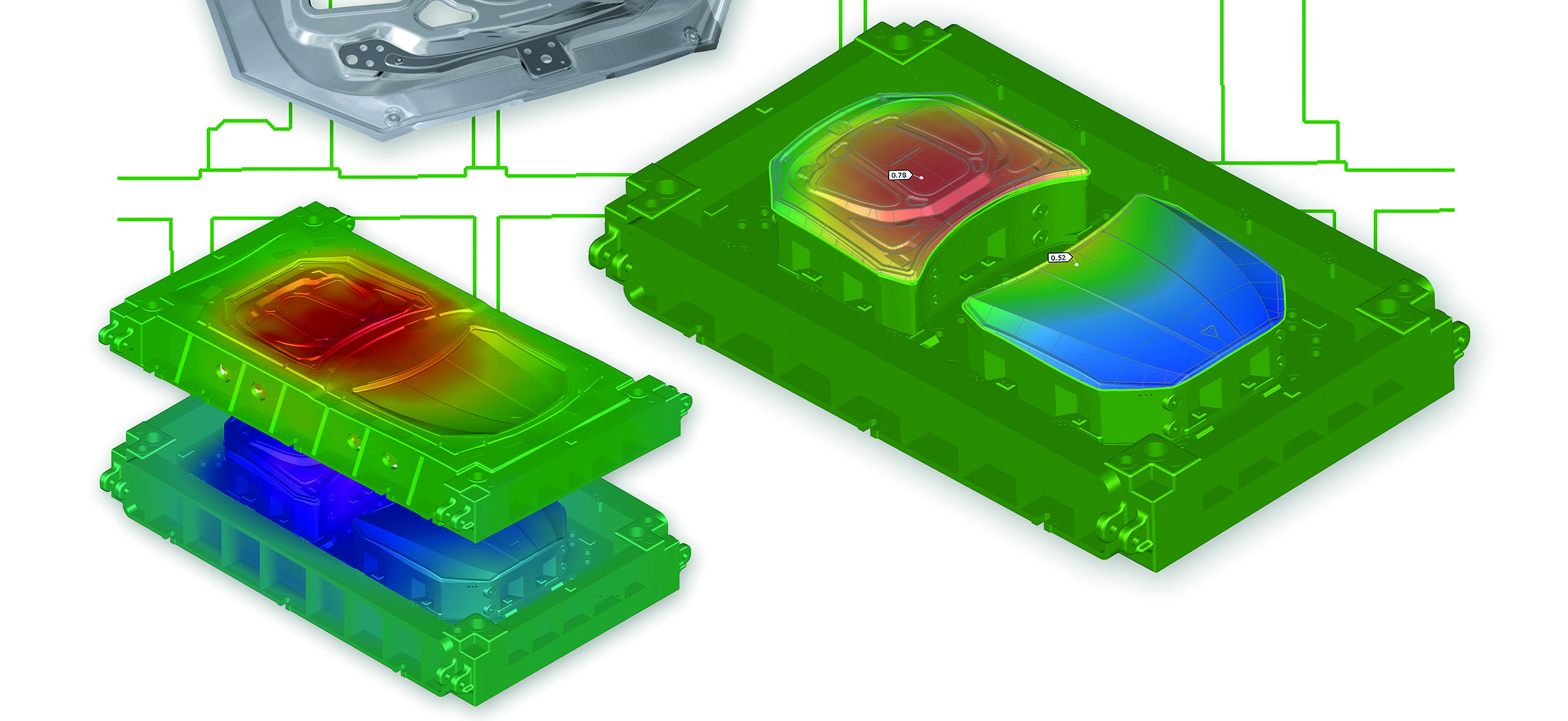

The new AutoForm-ToolDeflect software enables efficient analysis and compensation of elastic tool deflection – a process called crowning. The software can be easily used in both the early method planning phase and the final validation phase, allowing users to avoid unnecessary tryout loops and thereby improve production efficiency.

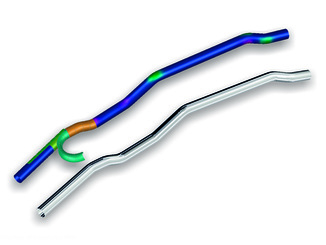

Tool deflection is a major issue in the manufacture of tools and stampings, as it leads to increased tryout grinding, scrap and press downtime in production. To ensure efficient production, the deflection must be compensated. AutoForm-ToolDeflect allows the user to compensate for elastic tool deflection by automatically crowning the tool surfaces.

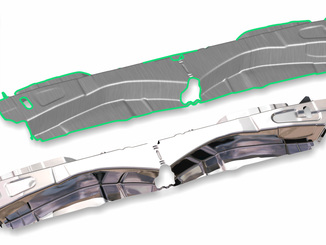

AutoForm-ToolDeflect can be used in the early stages of process design, when the final tool geometry is not yet available in CAD. The newly developed ‘Substructure Generator’ allows users to create a tool structure design so that initial tool design concepts can be defined quickly and purely based on part geometry. By analyzing various alternative concept designs, the user can select the most effective design with minimal elastic tool deflection.

The software can also be used in the final validation phase by using existing final mold geometry data from CAD. After calculating the tool deflection, the user can perform crowning. The results of the crowning can then be used for milling preparation. In this way, AutoForm-ToolDeflect enables users to avoid unnecessary tryout loops and thus increase production efficiency.

Dr. Markus Thomma, CMO of AutoForm Group, explains, “Reducing tryout loops has always been an important issue in the tooling industry, because every avoided correction loop brings an immediate time and cost advantage. Our newly developed AutoForm-ToolDeflect software greatly supports customers facing such issues.”

Background

AutoForm Engineering GmbH provides software solutions for sheet metal forming and body-in-white processes. More than 400 highly qualified employees in this field work at AutoForm. The company is considered one of the leading providers of software for product manufacturability assurance, tool and material cost calculation, tool design and virtual sheet metal forming, and body-in-white process optimization. All of the top 20 automotive manufacturers and most of their suppliers use AutoForm’s software. The company is headquartered in Switzerland. Subsidiaries in Germany, the Netherlands, France, Spain, Italy, the Czech Republic, Sweden, the USA, Mexico, Brazil, India, China, Japan and Korea underline AutoForm’s international presence. In more than 10 other countries, local sales partners ensure proximity to customers.

Web:

www.autoform.com