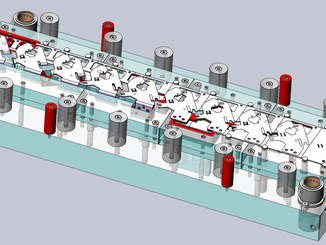

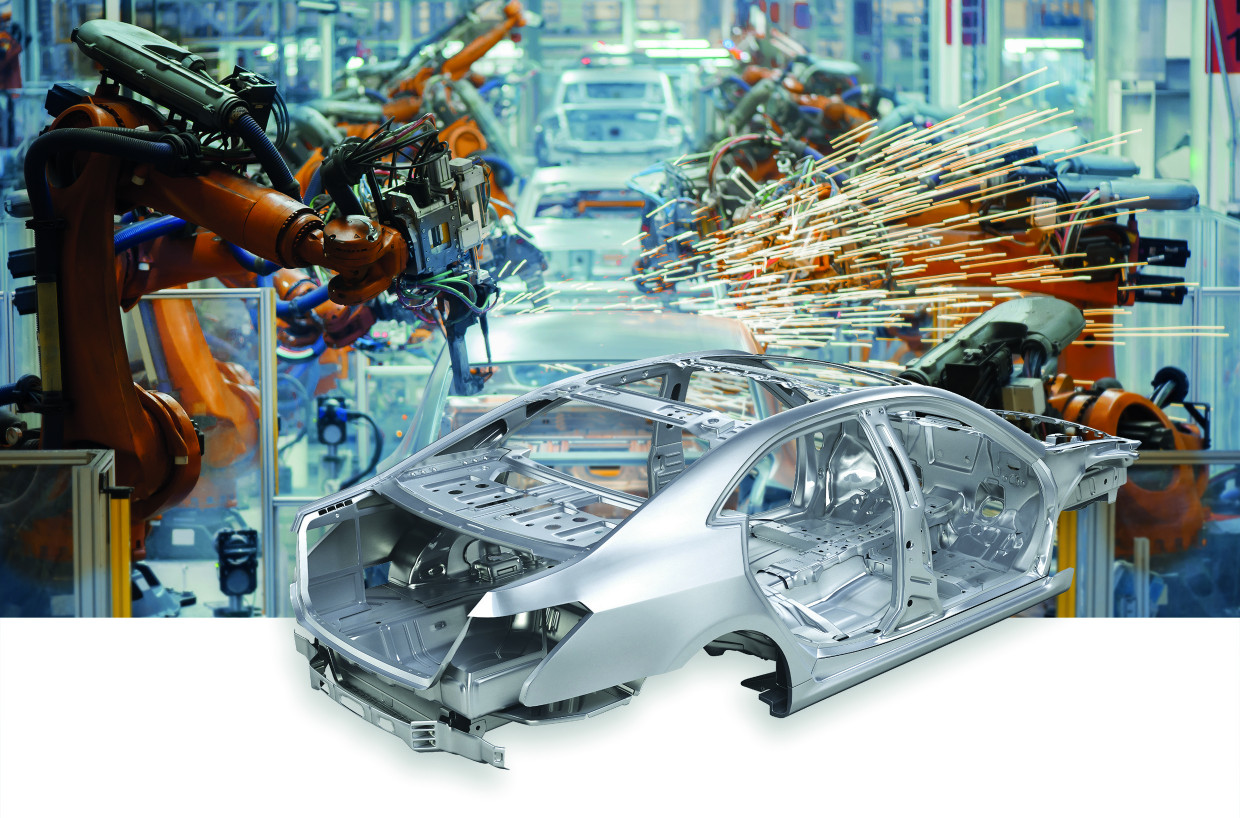

AutoForm Engineering, a leading provider of software solutions for sheet metal forming and body-in-white processes, has launched its latest software version, AutoForm Assembly R11. This version offers new functions and improvements for the joining process, the shell construction process and the dimensional accuracy of the entire shell construction.

AutoForm Assembly R11 enables the virtual optimization of body-in-white processes. The most important new functions and enhancements that have been developed for the joining process, the shell construction process and the dimensional accuracy of the entire shell construction are:

– Support for laser line welding: With the latest version, users can take into account the thermal effects of laser line welding. This newly developed option for the joining process makes it possible to specify welding speed, power consumption and efficiency as process parameters in order to calculate the thermal load on the heat-affected zone. Based on the change in local strains and stresses, the user can determine the effects of thermal effects on the dimensional accuracy of the assembly.

– Assembly simulation taking into account the real part geometry: With this software version, users can also carry out assembly simulations in the process development phase, when the first produced stamped parts are already available. The new function enables simulation results of individual stamped parts, such as elongation, stresses and thickness distribution, to be mapped onto scanned part geometries from production. This type of illustration more accurately reflects the condition of the stamped parts produced. This is particularly important as input for the body shell simulation, as the combination of real geometry and the physical state of the stamped part ensures more accurate simulation results for the body shell parts.

– Better match with reality: With the improvements in the latest software version regarding the description of boundary conditions in shell and measurement operations, users have better control over the process definition and can achieve a more consistent match with reality.

Thanks to these and other new functions and enhancements, users are optimally equipped for designing the shell construction process, from early feasibility studies and process development through to tryout and production support.

Web:

www.autoform.com