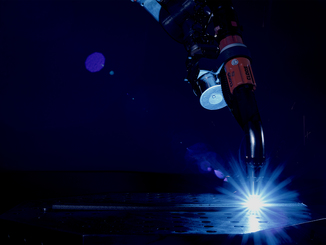

As a specialist in the production of larger formed parts and complex welded assemblies made of steel, stainless steel and aluminum, Kohl & Sohn GmbH places the highest priority on product quality. For the production of battery hoods of industrial trucks, the company relies on automation solutions from Cloos. After the components have been welded with Cloos robots, another robot takes over the automated rough and fine grinding.

© Cloos

Whether metal forming, welding, cutting, toolmaking, metrology, surface finishing or coating – Kohl & Sohn uses a wide range of manufacturing processes to produce sophisticated components made of steel, stainless steel and aluminum. The company delivers complex welded assemblies or ready-to-install parts just-in-sequence directly to the assembly line. Whether components for agricultural machinery, battery doors and hoods for forklifts, chassis for electric pallet trucks or elements for automated logistics systems – many customers appreciate the high manufacturing quality of the traditional company. Founded in 1897, Kohl & Sohn is the oldest company within Kohl Gruppe AG. Today, the group employs a total of around 450 people at its three sites in Cologne and Slubice in Poland.

Continuous investment in manufacturing

“In addition to the high technical demands on the quality of the products, our customers expect maximum flexibility from us as a supplier,” explains Managing Director Hubertus Müller. “Since we specialize in the production of small and medium quantities, we have to continuously adapt and expand our machinery in order to be able to respond to changing customer requirements in a timely manner.”

In 2018, Kohl & Sohn invested in a new robot system for automated grinding of welded components. At the Cologne site, the company uses nine robotic systems for automated welding in addition to the grinding system. In addition, there are around 15 welding power sources for manual welding. The company uses another welding robot system at its Polish production site in Slubice.

Kohl & Sohn planned and implemented the automatic grinding system together with Cloos and FerRobotics. While Cloos contributed its robot and plant engineering know-how to the joint project, FerRobotics contributed its expertise in sensitive robotics with patented force-contact intelligence, and Kohl & Sohn contributed its expertise in grinding applications. “Our grinding system was the first joint project between Cloos and FerRobotics. We solved all challenges in partnership,” Müller is pleased. “The collaboration with our two partners has been excellent.”

© Cloos

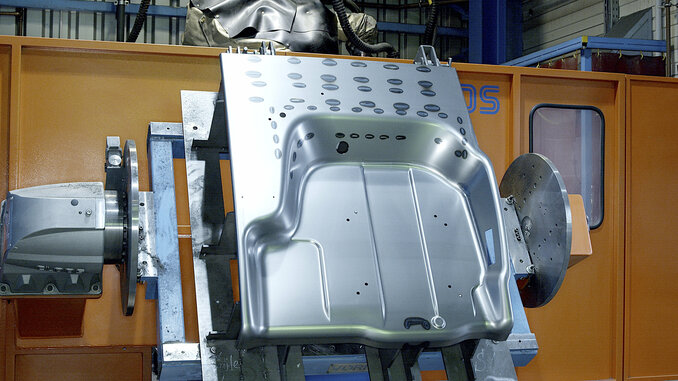

Two-station robot system

The robot system consists of two stations. Both stations have two vertically arranged face plates. The workpiece is rotated about a horizontal rotary axis to the optimum machining position. The station is changed by a horizontal turning movement. The two-station principle makes it easy to load components in one station while the robot grinds in the other.

Different grinding techniques in one system

The robot is equipped with a tool changing system. This allows maximum manufacturing flexibility, as different grinding applications can be used depending on the application. Kohl & Sohn uses the Active Orbital Kit (AOK) and Active Angular Kit (AAK) from FerRobotics. The AOK is a system package optimized for robotic use with an industrial-grade random orbit sander for structure-free surface finishing of all materials. The AAK includes an enormously resilient robot-compatible angle grinder for the automation of grinding processes. The compact and lightweight grinding applications offer the highest process quality.

Intelligent additional functions

In addition, a grinding media changing station is integrated into the system. Here, the grinding media are exchanged quickly, easily and automatically. The grinding media change is controlled via a sensor. A sensor query monitors the fill level of the magazines.

In addition, the Cloos Grind Control Interface GCI 1.0 provides an optimal man-machine interface to the Cloos robot system. All process parameters, from rotation speed to contact pressure and feed rate, can be controlled individually at the same time. The Cloos Grind Control Interface GCI 1.0 enables simple and intuitive control as well as extensive diagnostic options with set and actual values.

© Cloos

Efficient manufacturing processes and highest quality

In the past, the components were machined by hand. Here, there can be fluctuations in the amount of effort required to achieve the required quality, as the grinding result is highly dependent on the sensitivity of the respective employee. This dependency is eliminated when using the robot. Due to the precise technology, it offers a consistently high quality with reproducible results. At the same time, production capacity is now less dependent on the availability of individual employees.

Overall, Kohl & Sohn was able to significantly speed up the manufacturing processes by switching to the automated grinding technology and the reduced non-productive times. Another positive effect of the use of robots is the reduced consumption of grinding wheels. Due to the constant pressure conditions during automated grinding, significantly fewer grinding wheels are required than during manual grinding.

Robot use improves working conditions

Last but not least, the employees also benefit from the use of the new technology and the improved working environment. The robot plant offers employees a challenging and exciting workplace. While the robot does the physically heavy lifting, they can focus on process monitoring. The general hazard from sparks, emissions and heat is significantly lower than with hand grinding. In order to take full advantage of the innovative technology, the employees were intensively trained by Cloos. In the meantime, five employees have been trained to work on the robot system. This enables the robotic system to produce continuously in three-shift operation.

Robot and welding technology from a single source

Since 1919 Carl Cloos Schweißtechnik GmbH has been one of the leading companies in welding technology. With more than 800 employees worldwide, the company realizes manufacturing solutions in welding and robotics for industries such as construction machinery, rail vehicles, energy, automotive and agriculture. The modern Cloos welding power sources Qineo are available for a wide range of welding processes. Using Qirox robots, positioners and fixtures, Cloos designs and manufactures custom automated welding systems. Cloos’ particular strength lies in its broad-based expertise. Because – starting with welding technology, robot mechanics and control, up to positioners, software and sensor technology – at Cloos everything comes from one source.

Web:

www.cloos.de