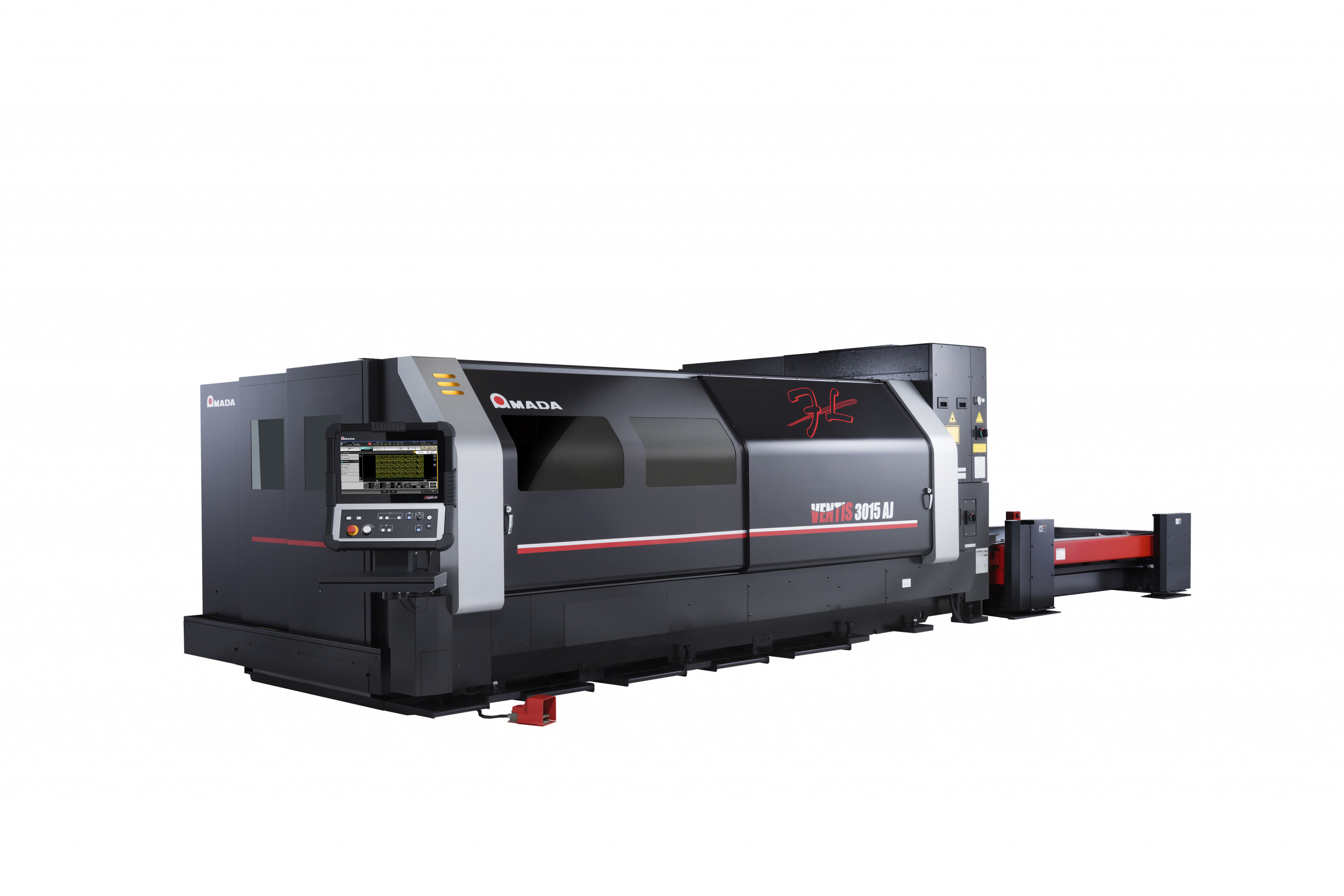

2023 was another successful year for Amada. The 200. Ventis-AJ 4 kW fiber laser, which achieves an output similar to that of a conventional 6 kW solid-state laser thanks to Locus Beam Control (LBC) technology, was sold in Europe. Following a successful premiere at the production site in France, Amada has also launched the 6 kW version on the market. According to the supplier, this higher-power variant offers comparable performance to a conventional 8 to 10 kW fiber laser.

Following its market launch at the end of 2019, the 100th order for the 4 kW Ventis-AJ fiber laser from Amada. The 200. The first order was placed less than 15 months later, which shows that European customers are increasingly accepting the benefits of LBC technology. In recent years, customers have focused on achieving productivity comparable to that of machines with higher output while consuming less energy, in order to reduce the overall cost per part and increase competitiveness. This is precisely where the Ventis AJ comes in.

The French company RDS, based in Vernouillet near Dreux, has ordered the 200th RDS. Ventis AJ fiber laser with 4 kW in Europe. RDS supplies various industries, including the construction, automotive, pharmaceutical, food and aerospace sectors. The company currently has Amada bending and shearing machines. The Ventis-AJ 4 kW is the company’s first Amada laser. It replaces a competitor’s machine and aims to increase productivity while using less energy.

Over 30 orders have already been placed for the 6 kW Ventis AJe, which was launched in October 2023 at Amada’s production facility in Charleville-Mézières, France. Over 200 existing and potential Amada customers from all over Europe attended the premiere of this more powerful version.

The new version introduces two new technologies for laser processing: Firstly, LBC Flash Cut enables small holes to be cut without having to move the laser head. The LBC unit generates the circular movement, which greatly increases the number of holes that can be machined per second. Secondly, soft-joint technology is a completely new method of holding parts in a sheet without micro-corners by using the thermal deformation of the material to hold the parts in place. This eliminates the possibility of parts tipping and makes the processing of smaller parts much more reliable.

The 6 kW Ventis AJe is also equipped with the new AMNC-4ie control system. The new control system has been specially developed to make machine operation more intuitive and less reliant on highly skilled operators. It has several new functions: Face recognition can automatically switch the language to one of the 15 stored languages, while reducing workflows and improving work efficiency. Automatic sheet nesting also optimizes material utilization, while the Mobile HMI function enables the analysis of multiple machine data via smartphone technology. Videos with maintenance instructions can also be displayed on the control unit or transferred to a mobile device.

The machine was equipped with all the functions of Amada’s LIS (Laser Integration System) to enable more autonomous production. Functions such as automatic nozzle centering, monitoring of the protective glass and automatic restoration of cutting readiness in the event of collisions enable the machine to work for significantly longer periods without operator intervention. With the ability to process thick structural steel of various qualities without changing the cutting data, to produce stainless steel parts without burrs and to cut aluminum at the same speed as conventional 10 kW fiber laser machines, the Ventis-AJe 6 kW opens up new possibilities with noticeably lower power consumption.

Background

The Amada Group is one of the world’s leading manufacturers of sheet metal working machines. Amada GmbH offers a comprehensive range of cutting, bending, welding, punching and laser technologies. Modular automation components, software applications and a wide range of tools complete this offer. In addition, Amada offers its customers a wide range of services. The Amada Group was founded by Isamu Amada in Japan in 1946. The German subsidiary Amada GmbH has been in existence since 1972.

Web:

www.amada.de