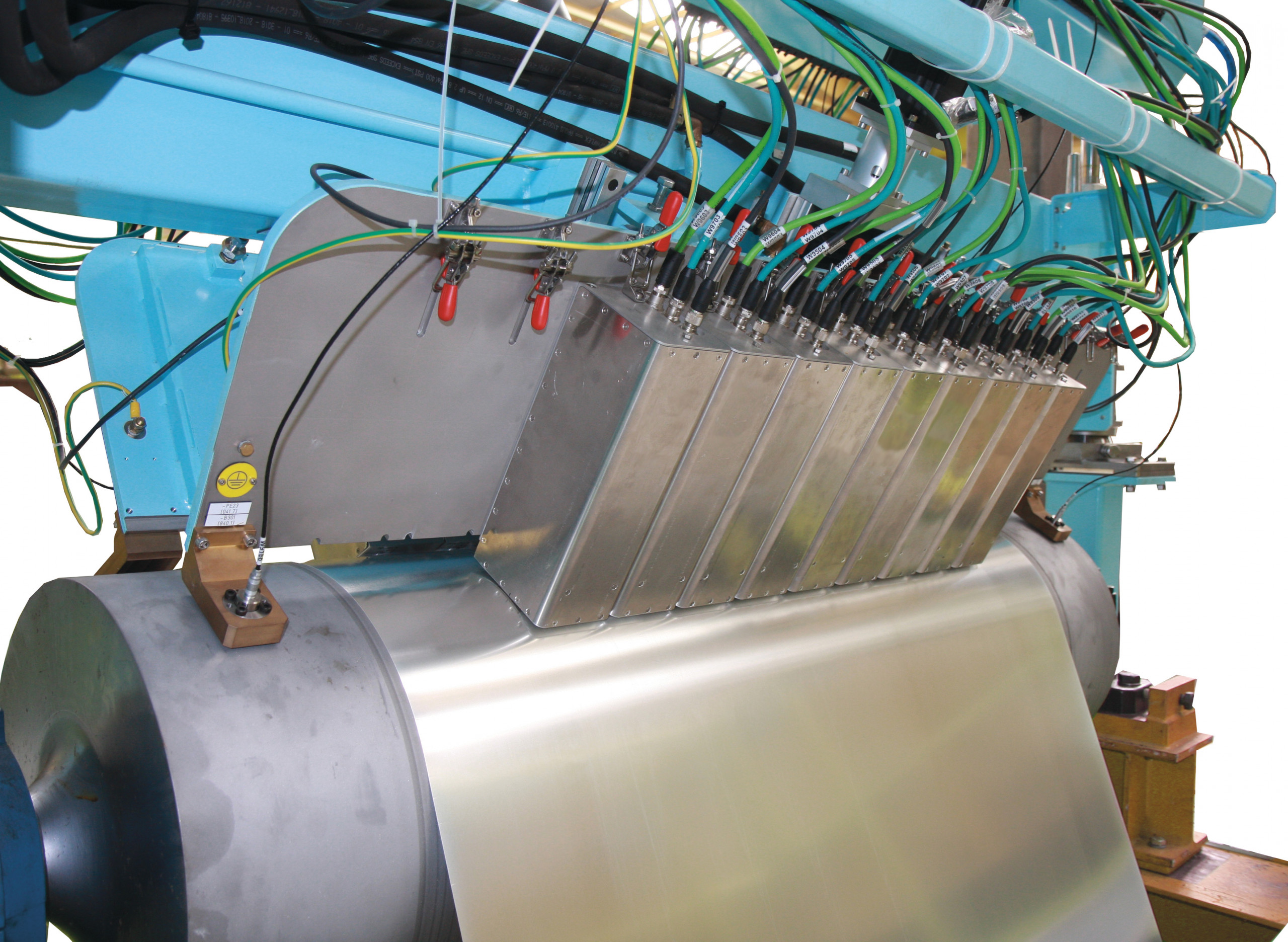

Metal Production

UKP laser structures and polishes hard material components in a single clamping operation

Tools made of hard materials and ceramics such as tungsten carbide are particularly wear-resistant. However, the tools used to manufacture them wear all the faster – unless the tool is […]