Today, the transport sector is responsible for the majority of global greenhouse gas emissions, accounting for around 25 per cent of the total. Just like other energy-intensive sectors, which include the metals industry, it faces the challenge of achieving ever stricter targets for decarbonisation in order to become more climate-friendly and reduce the consumption of non-renewable resources.

As part of its commitment to reduce CO2 emissions and its goal of becoming climate neutral in the medium term, SMS Concast, a company of the SMS Group based in Zurich, has entered into a strategic partnership with the Swiss company Synhelion and has invested heavily in the company’s state-of-the-art solar technology. The financial resources contributed by the SMS Group and other partners will enable Synhelion to build and operate the world’s first solar fuel production plant.

A major contribution to tackling the climate crisis

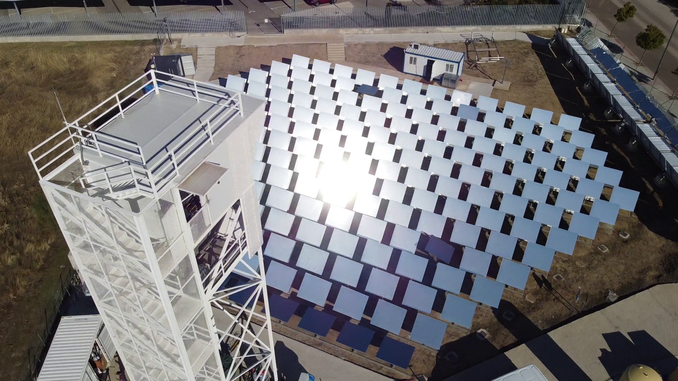

The facility in Jülich, Germany, will cover the entire process from the concentration of sunlight to the production of synthetic liquid fuel on an industrial scale. With this plant, Synhelion can produce solar fuels at such a low price that they can compete with fossil alternatives.

In this way, the company and its partners are making an important contribution to tackling the climate crisis. This is especially true for sectors like aviation that are difficult to electrify. Moreover, long-distance transport or transport over long distances by cargo flight or by sea require extremely high energy densities that cannot be achieved with current battery technology. Liquid synthetic fuels, on the other hand, such as those Synhelion intends to produce, can achieve these densities, making them an ideal energy source.

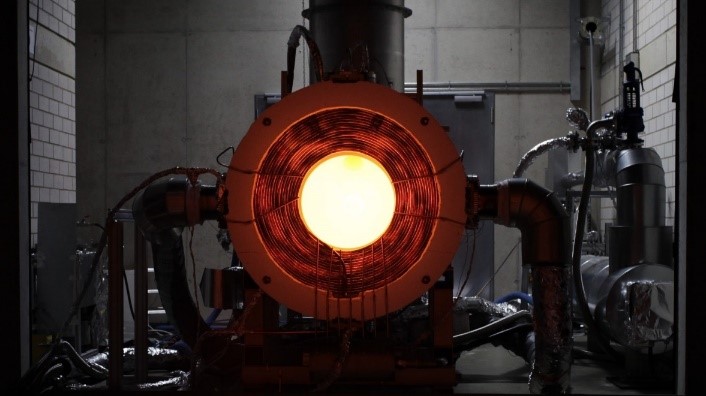

Although the initial focus of Synhelion’s developments is on transportation, the process includes solar technologies that can be applied to other sectors. In the metal industry, the process heat generated by the sun can be used at unprecedentedly high temperatures in excess of 1,500 degrees Celsius, for example, for energy-intensive processes in steel production.

© Synhelion

Sun-to-liquid technology and “solar steel

Synhelion uses solar heat to convert CO2 into synthetic fuels, so-called solar fuels. The solar radiation is reflected by a mirror field, concentrated on a receiver and converted into high-temperature process heat. The heat thus generated is fed to a thermo-chemical reactor which converts CO2 and H2O into synthesis gas, a mixture of H2 and CO.

The synthesis gas is then processed into fuels such as gasoline, diesel or jet fuel using standard gas-to-liquids technology. Excess heat is stored in the thermal energy storage (TES) to allow continuous 24/7 operation.

“We immediately recognized the potential of this innovative process from Synhelion, a spin-off from ETH Zurich. Beyond solar fuels, the technology offers many applications in the steel industry, both for the SMS Group and for our customers. It helps to drive the green transition and thus the development towards a CO2-neutral and sustainable metal industry. The SMS Concast team is looking forward to a fruitful partnership with an intensive exchange of knowledge,” says Dr. Stephan Feldhaus, CEO of SMS Concast.

On the way to an emission-free future

Dr. Philipp Furler, CEO and founder of Synhelion, comments: “SMS group will support us with its extensive know-how in plant design and operation as well as in environmental engineering. Together we will accelerate the commercialization of our unique, proven technology worldwide and integrate our solutions, such as thermal energy storage, for further applications in the metals industry.”

Tim Ovelgönne, Corporate Development at the SMS Group and responsible project manager, adds: “We see very great potential in the sun-to-liquid technology as it can be used in various industries. We are excited about a very promising partnership with the team at Synhelion. This investment is an important step in SMS group’s decarbonization strategy.”

About SMS Concast

SMS Concast, a company of the SMS Group, develops continuous casting technology for the manufacture of long products in steel production. The company was founded in 1954 by Irving Rossi to build continuous casting machines, and its headquarters are still located in Switzerland. SMS Concast supports manufacturers in all project phases: from engineering (design and order processing) to delivery and commissioning of the plants. Together with the partner companies of the SMS Group, SMS Concast builds complete steel and rolling mills in search of ever more sustainable solutions.

About Synhelion

Synhelion is a global pioneer in the field of sustainable solar fuels. The cleantech company was founded in 2016 as a spin-off of the Swiss Federal Institute of Technology Zurich (ETH Zurich). Solar fuels can replace fossil fuels in all areas of application, as they are economical and compatible with the existing infrastructure worldwide. Synhelion’s unique technology converts concentrated sunlight into the hottest process heat on the market. This means that a large number of industrial processes can be operated with solar heat, for example the production of fuels and cement. The company already works with international partners such as Lufthansa Group, Wood, Eni, Cemex and Zurich Airport.