At the end of May, Tagmet, part of TMK’s Pipe Metallurgical Company in Taganrog, Russia, produced the five millionth ton of pipe on the PQF (Premium Quality Finishing) seamless pipe line supplied by SMS. For the production of this anniversary batch of oil line pipe with a diameter of 168 millimeters and a wall thickness of 18 millimeters, continuously cast starting material from a steel mill also supplied by SMS was used.

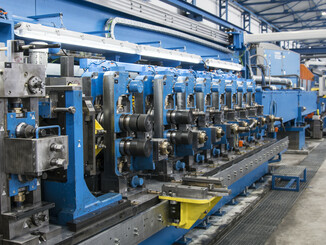

The continuous PQF pipe mill at Tagmet commissioned by the SMS Group in 2008 was the first pipe mill in Russia to use PQF technology for the production of seamless steel pipes for the oil and gas industry.

Today Tagmet, with its six thousand employees, is one of the leading companies in the pipe industry, both nationally and internationally. The plant produces almost all types of seamless steel tubes in the size range from 73 to 273 millimeters, including high-strength tubes with special properties to meet the ever-increasing demands of the market.

MS Group is a group of internationally active companies in plant and mechanical engineering for the steel and non-ferrous metals industry. Around 14,000 employees worldwide generate sales of more than 2.9 billion euros. The sole owner of Holding SMS GmbH is the Weiss Family Foundation.

“Undoubtedly, the record is a merit of the entire plant staff. The components of the success are well-coordinated actions of all technical services of the plant, which maintained the equipment to ensure stable and flawless production, and all workers involved in the technological process,” said Sergey Bilan, Managing Director of Tagmet.Over the years, the trustful cooperation between Tagmet and SMS Group led to constant development of technology in the PQF seamless tube plant. Proof of this is the current order placed by TMK for the supply of a newly developed mandrel abutment for the taper piercing mill. The final assembly of the mandrel abutment is currently being carried out in the workshop of the SMS Group.