Recently, EJP Wire Technology GmbH, EJP Italmec Sp. z o.o. and WWM Technology srl under the umbrella of EJP Industries and present their innovations together: a new system for loop descaling of wire and the new generation of cleaning and copper plating equipment for welding wire production.

In the EJP Industries Group, three companies focus on equipment for the production and treatment of wire:

– EJP Wire Technology in Schwerte: Plants for the pretreatment of wire

– EJP Italmec in Katowice (Poland): Plants for the production of low, medium and high carbon wire.

– WWM Technology in Conselve (Italy): Equipment for the production of welding wire

With them, EJP is one of the few suppliers that produce complete plants for the entire “wire” process chain and at the same time have a worldwide sales and service network.

© WWM

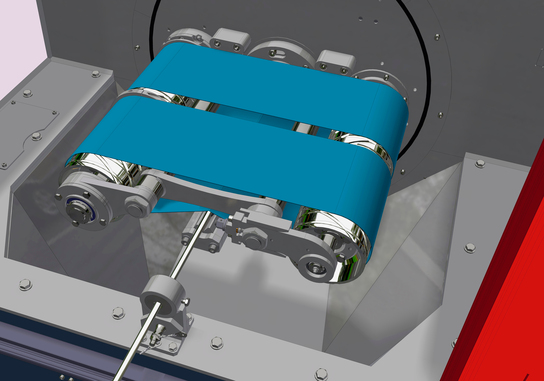

For the loop descaling of wire in continuous operation, EJP Wire Technology is presenting the fundamentally revised SA-2 belt grinding system for the first time at the trade show. In contrast to the machines commonly used to date, it operates with just one rotating working head on which two sanding belts with different grit sizes can be mounted … for coarse and fine sanding, for example. With a much simpler design, it achieves the same effect as the previously common double-headers.

Lothar Köppen, the managing partner of EJP Wire, has already been working in his profession since 2004 and knows the practice: “In the new plant, there is only one working head that rotates. Even with two grinding belts, this guarantees a consistent surface quality of the wire surface. The previously required, time-consuming synchronization of the speed with the wire speed is no longer necessary. And what’s not there can’t cause any malfunctions.”

WWM presents the new generation of cleaning and copper plating equipment for welding wire production at the fair. The new systems, which operate on the principle of chemical copper plating, increase the production speed from 15 to 30 m/s while maintaining the high quality of the wire. They can be combined with dry or wet drawing machines, for example with the slip-free wet drawing machine that WWM Technology presented at the last Wire. EJP Italmec will show the range of equipment for the production of low, medium and high carbon wire.

Wire Hall 11, Booth D06

Tube Hall 9, Booth A12

Web:

www.ejpwire.com