An investment in the new Stopa LG-E long product storage system can open up trend-setting perspectives. Operators benefit from modular components that allow them to adapt their production processes to growing or changing market expectations.

© Stopa

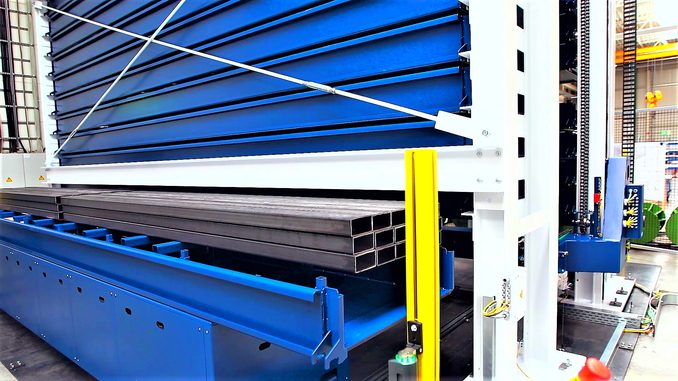

The LG-E long goods storage system (based on EcoPlus) developed by Stopa Anlagenbau offers a high degree of space utilization and fast access to the long goods. Other advantages include clear, space-saving storage, less material damage, easy handling and a short-term return on investment. In the function of the long material store as a link between the stocked material and the processing machines to be supplied, the system supported by software enables rapid storage and stocktaking.

In contrast to flat storage, the LG-E long goods storage system allows the use of cassettes with different loading heights, which, for example, can accommodate 155 mm square tubes weighing up to 1.5 t. From 215 mm, the load capacity reaches up to 3 t. The maximum loading height is 500 mm. Added to this is a more precise inventory overview, based on integrated inventory management or optional warehouse management software (WMS). Further plus points are the fully automated sequence up to the storage and retrieval process, user-friendliness, ergonomics and thus a lower risk of errors.

Important unique selling points

With the LG-E long goods storage system, Stopa presents a flexible entry-level product at a favorable price-performance ratio. The flexibility is based on transport trolleys and chain conveyors that can be operated from both sides. Compared to previously common entry-level products, LG-E is equipped with significantly higher speeds. In a market comparison, these advantages and the comparatively high station variance form the basis for implementing a large number of material storage and retrieval operations. Additional benefits include material management provided for in the standard, a second-tower solution that could be retrofitted if necessary, and station trolley connections.

© Stopa

Direct supply of the processing machines

The Stopa LG-E, through the flexible arrangement of chain conveyors and/or connections of station trolleys, makes it possible to supply the material directly to the machines without tying them up. In parallel, an additional station can be used to store material or retrieve it to other machines.

The machine operator can conveniently request the required long material via the optionally available LVS and LVS clients positioned close to the machine. If required, the stations can transport the material to the processing machine in automatic mode, so that manual removal and transfer to the machine are reduced to a minimum.

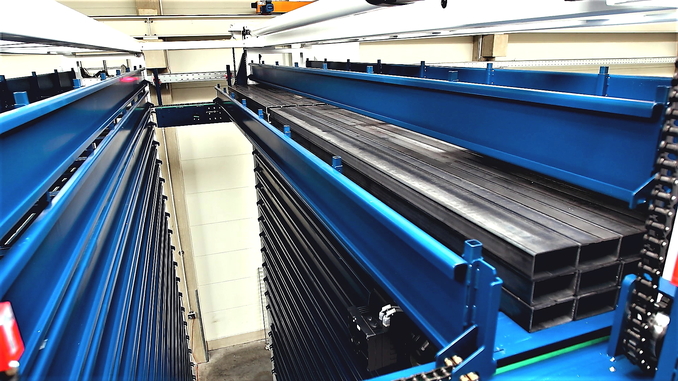

The material can be transported to the warehouse, for example, by forklift trucks, overhead cranes or slewing cranes and deposited in the robust and solid cassettes. For storage by forklift, Stopa has a transport cart with material excavation, which facilitates storage with forklifts. In addition, the manufacturer offers the alternative of setting up the storage system inside the hall close to an external wall, having a transport trolley drive outside through a roller shutter and storing the material directly at the delivery point. For example, the warehouse could be placed near a roller conveyor to load it directly from the retrieval station with an indoor or slewing crane. In turn, the conveyor system could be used to supply a saw, a pipe laser, a bending machine, and other processing machines designed for manual loading.

Alternative storage and retrieval

The concept of the LG-E long goods storage system is designed for three different storage and retrieval stations. One example is a chain conveyor to which the storage and retrieval machine (SRM) transfers the respective cassette, which is positioned outside the warehouse. From there, the material can be unloaded from the cassette, which can be opened on both sides, and transported to the downstream machines along a variable conveyor path length. The return stock is loaded into the cassette.

Instead of chain conveyors, Stopa sometimes uses transport carts, which are installed with or without excavation, as required. In the case of transport carts without excavation, the SRM transfers the cassette to the cart, which moves the load carrier, according to the sequence of the chain conveyor, to a position outside the warehouse. The transport carriage has the option of moving to a parking position in the steel structure, which is designed for 100 percent payload, so that the travel path remains clear. Compared with the transport truck without excavation, the one with excavation has the advantage that forklifts are able to load and unload the material more easily.

© Stopa

Warehouse management software with a wide range of functions

Thanks to the optional LVS, the LG-E long goods storage system offers a wide range of functions. For example, the aforementioned convenient restocking of material as well as the management of remnants and of partial compartments in a cassette.

When using the WMS, the customer’s ERP system can be connected to the warehouse via interfaces (CSV/XML, ODBC or ADO). This allows inventory data to be exchanged and transport orders to be issued that contain all the information required for storage as well as optional accompanying information for material tracking. In this respect, the operator benefits from complete documentation of the stored goods. In addition, some of the manual entries made by employees are reduced to a minimum because the software generates the transport orders automatically. This is an advantage that is significantly noticeable in terms of the reliability of inventories, which are managed as total and partial stocks.

An important point is also the simple and intuitive user guidance on the clear graphical program interface. Which features are to be considered important depends on the individual needs of the customer. The Stopa LVS, which can be used after only a small amount of training, offers a wide range of functions that can be adapted to the desired requirements. With this in mind, all functions can be configured separately and program parts that are not required can be hidden from the workers so that they benefit from more clarity. In addition, it is possible to restrict the access rights of individual users to defined areas of the ERP system using the rights control function, which has also been installed.

Minor malfunctions can be quickly resolved by the Stopa service through the optionally available remote maintenance. In addition, the LG-E long goods storage system can be equipped with the TelePresence portal for remote diagnostics. A solution that meets the highest demands in terms of IT security.