The energy turnaround is a task for the century. And it also starts in Gelsenkirchen, at electrical steel specialist thyssenkrupp Electrical Steel. The company produces high-quality grain-oriented electrical steel, which is indispensable for the construction of low-loss power transformers for the transmission and forwarding of electrical energy. Now, for the first time, this basic material, which is essential for successfully mastering the energy transition, has been delivered to a customer with significantly reduced CO2 intensity.

The first quantities of Bluemint Powercore with 50 percent lower CO2 emissions will be supplied to the Regensburg-based company SGB-SMIT to be used to manufacture transformers for new, digital E.ON medium-voltage substations.

Back on track for success

Thyssenkrupp Electrical Steel says it is the European market leader for grain-oriented electrical steel. The elaborately manufactured special material ensures that transformers operate with a high degree of efficiency in order to transform energy with as little loss as possible. The lower the losses of the electrical steel strip, the higher the efficiency. Grain-oriented electrical steel from thyssenkrupp’s Powercore brand is used among other things in distribution and power transformers, but also in charging columns for e-cars and innovative electric motors.

The Gelsenkirchen-based company is back on track for success after a tight turnaround and performance program. Managing Director Georgios Giovanakis: “We have made targeted investments and also brought additional engineering know-how into the workforce. The aim was and is to produce the technologically sophisticated top grades that are in particular demand on the market, which are characterized by particularly low core losses and thus achieve high efficiencies in current conversion.”

The use of these grades enables customers to manufacture transformers that meet the demanding efficiency specifications under the EU Code Design Directive. In this way, they contribute to reducing global energy demand and the associated CO2 emissions. “Through the technological turnaround at our three plants in Germany, France and India, we are delivering improved products to our customers. As a result, we indirectly contribute to energy savings of more than one thousand gigawatt hours and thus to the avoidance of more than 400,000 tons of CO2,” adds Giovanakis.

It is the clear goal of the Gelsenkirchen-based company to significantly increase the production of top grades with high efficiency in particular. If the low-CO2 generation of electricity from renewable sources dominates in the future, the proportion of CO2 emissions generated during the production phase of the transformer will come into even sharper focus. Therefore, the next logical step is now to offer electrical steel itself in reduced CO2 intensity.

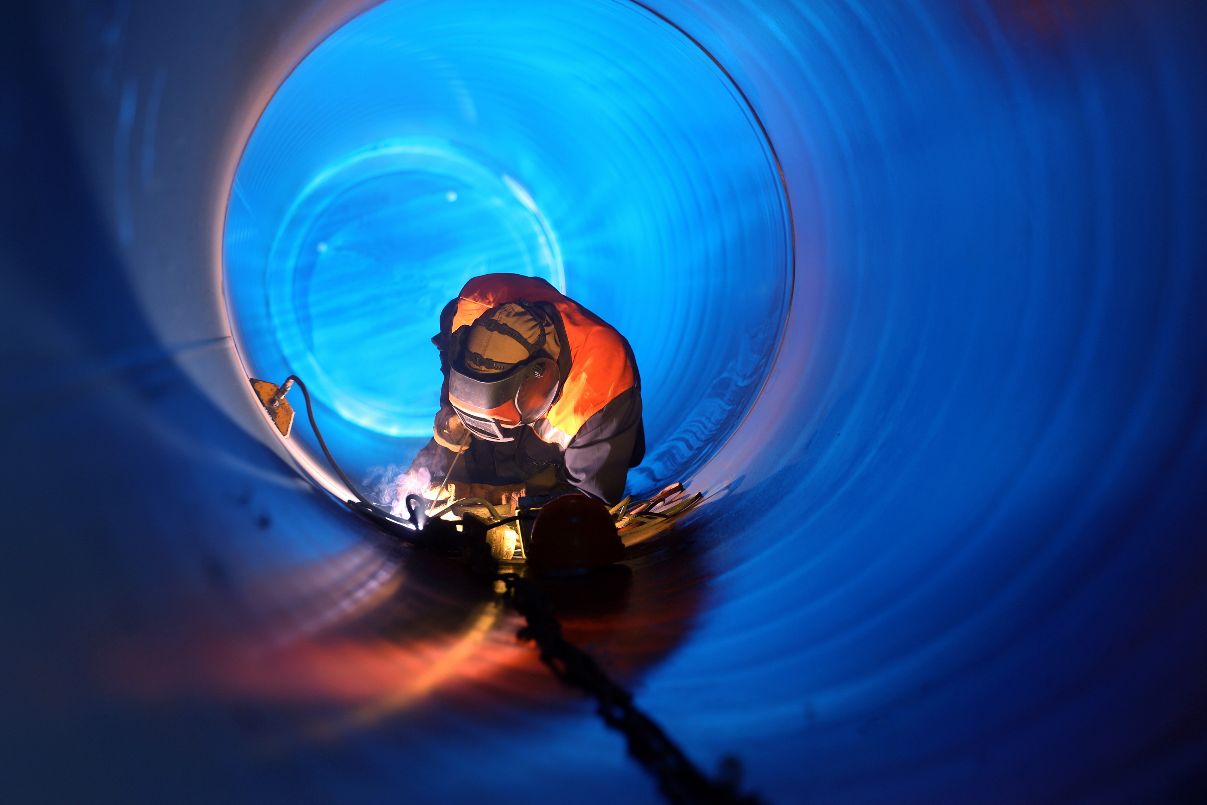

© Thyssenkrupp

Transformer builder SGB-SMIT receives first quantities of CO2-reduced Bluemint Steel

Electrical steel made in Gelsenkirchen is now available CO2-reduced for the first time. The first customer to receive Bluemint Powercore with a 50 percent lower CO2 intensity is transformer specialist SGB-SMIT from Regensburg, Germany. The company manufactures transformers that ensure the transport of electrical energy from the points of origin to the energy consumers.

“Energy suppliers and industrial companies all over the world rely on our products. For us and our customers, it is a great added value that thyssenkrupp’s top grades are now also available in CO2-reduced form. This is an important step towards further decarbonization of the energy process chain,” says Holger Ketterer, Managing Director of SGB-SMIT. The medium-sized company with a global customer base ordered Bluemint Powercore from thyssenkrupp for use in power and distribution transformers. “It’s also clear that the more green energy is generated and transported, the greater the importance of a climate-friendly supply chain and the use of climate-friendly materials,” adds Ketterer.

Since October 2021 thyssenkrupp Steel has been offering certified CO2-reduced steel under the Bluemint brand. Production will initially take place via the classic blast furnace route at the Duisburg site before the technological leap to hydrogen-based direct reduction technology from 2025. For the batch now delivered to SGB-SMIT, reduced iron has already been used in the blast furnace, enabling a reduction in coal usage. This results in actual CO2 savings in the primary steel route, which are converted on balance to a specific quantity of certified Bluemint Steel – while maintaining the same high quality and full range of grades.

Including all further processing steps in Duisburg and in Gelsenkirchen, a CO2 saving of 50 percent is achieved compared with conventional electrical steel. This means a reduction in the CO2 intensity of one ton of Bluemint Powercore from 3.7 tons to 1.8 tons.

The Gelsenkirchen site is aiming for complete climate neutrality in the medium term, for example by using green electricity and biomethane in production as early as this year.

Transformers with CO2-reduced steel for new stations

The energy company E.on also sees great potential in the more climate-friendly version of its well-known and proven products. “We are committed to a sustainable energy world for tomorrow – so it makes a big difference to the overall rating of a plant if a substation or green power station also uses transformers with CO2-reduced electrical steel,” says Achim Hübner, International Category Lead for Transformers at E.on. The first small series will be used by E.on subsidiary Avacon.

Transformers connect the individual voltage levels between electricity production and the end consumer when transporting electrical power. The fact that this transport functions efficiently and with low losses is also thanks to materials from thyssenkrupp Electrical Steel. Highly efficient electrical steel, whether in wind turbines, generators or transformers, is an indispensable base material for the energy transition.

“Climate protection and with it the energy transition are the defining issues of the next decades,” says Giovanakis. “With its products thyssenkrupp Electrical Steel is helping to achieve the climate targets. This spurs us on even more to further improve our products for the energy transition.”

Climate-neutral from 2045

thyssenkrupp Steel AG is one of the leading manufacturers of flat carbon steel. The Duisburg-based company employs around 26,000 people and, with an annual production volume of around 11 million tons of crude steel, is Germany’s biggest flat steel producer according to its own figures.

As a pioneer in the “climate transformation”, thyssenkrupp Steel has set itself the goal of producing 3 million tons of CO2-neutral steel per year from as early as 2030. By 2045, steel production is to be completely climate-neutral. Bluemint Steel, the first CO2-reduced product, was launched in October 2021.

With around 1700 employees, thyssenkrupp Electrical Steel is a global premium manufacturer of grain-oriented electrical steel products and sees itself as the market leader in Europe. With its PowerCore brand, the company offers the core material for the manufacture of energy-efficient transformers and large high-performance generators, and now, for the first time, CO2-reduced electrical steel as Bluemint Powercore.