Whether precision steel tubes for lightweight automotive construction or robust pipelines – the applications for hot-rolled steels are diverse and the requirements of the customer industries are increasing. Last but not least, the “footprint” left behind by the manufacture of many products is becoming increasingly important. At Tube, thyssenkrupp Steel therefore presented Bluemint Steel, the flat steel from Duisburg with reduced CO2 intensity.

Manganese-boron steel: premium material for lightweight automotive construction

High-strength precision steel tubes offer enormous potential for weight reduction in automotive engineering and are used in the drivetrain and chassis, among other things. MnB-alloyed Tubor steel grades from Thyssenkrupp Steel are very easy to form as delivered, have a uniform surface and are suitable for welded, cold-rolled or drawn precision steel tubes. They are characterized by a homogeneous and fine-grained microstructure with a low sulphur and phosphorus content. Segregation in the microstructure is significantly minimized by means of special process engineering measures. Thanks to optimized production in combination with an analysis tailored to the end application, Tubor steel grades offer higher strength combined with good toughness in the quenched and tempered condition.

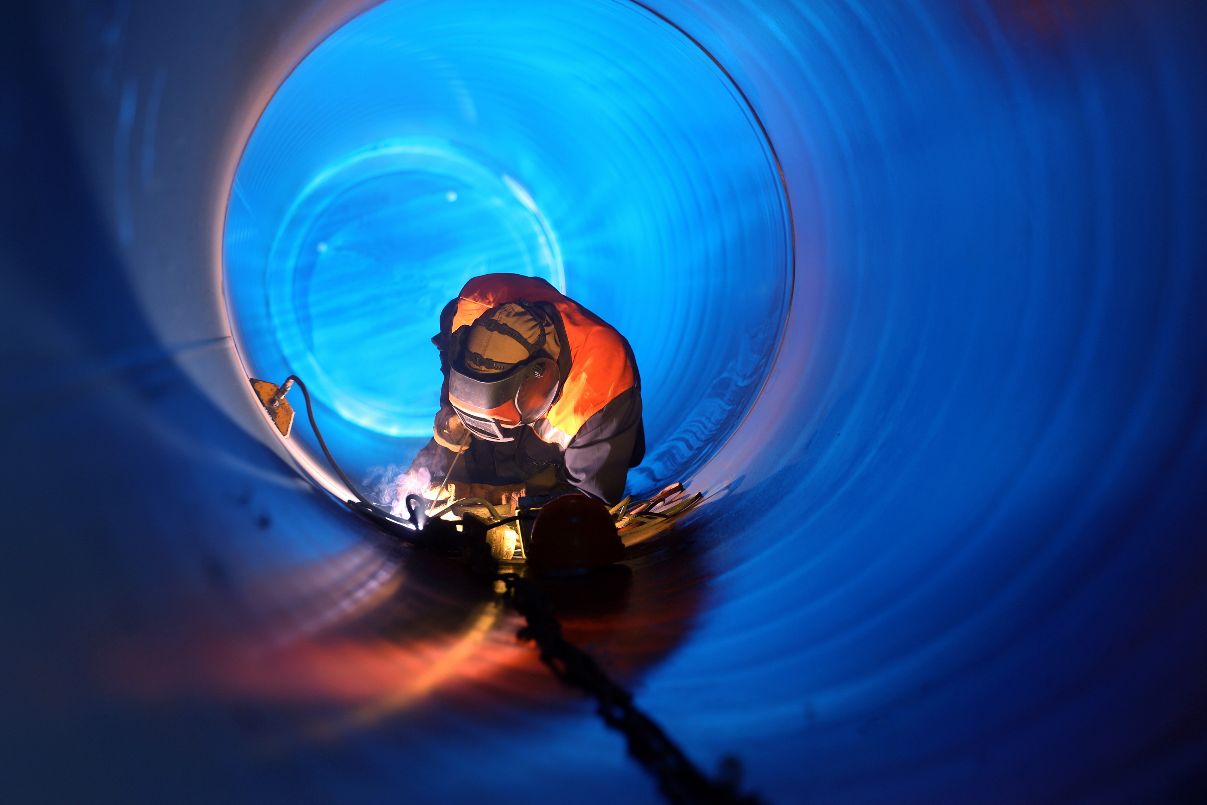

For safe transportation via pipeline: Steels for durable and robust line pipes

Steel for welded line pipes for the transportation of water, oil and gas as well as for the distribution of hydrogen and carbon dioxide must meet special requirements depending on the medium to be transported. Thyssenkrupp Steel supplies special steels for all applications of large-diameter pipes:

– Line pipe according to API 5L/DIN EN ISO 3183

– Pipes for the transportation of hydrogen in accordance with the EIGA Directive

– Sour gas resistant line pipe according to API 5L, Annex H

– CO2 transport lines according to ISO 27913

– Oil field tubes (OCTG) according to API 5CT

– Water pipes according to EN 10224 and API 5L

– Structural pipes and profiles in accordance with DIN EN 10219-1 and API 5L

For customers’ climate protection goals: Bluemint Steel and the TkH2Steel transformation project

With Bluemint Steel, the CO2-reduced steels, thyssenkrupp Steel is already supporting the climate protection ambitions of its customers. With Bluemint recycled, in the production of which scrap is used in the blast furnace process, thyssenkrupp Steel is reducing emissions at the Duisburg site and thus helping its customers to reduce their Scope 3 emissions. Bluemint Steel is available in the entire grade portfolio and in all dimensions.

However, the aim is to make the entire production process climate-neutral with the TkH2Steel transformation project. To this end, thyssenkrupp Steel is building a direct reduction plant at the Duisburg site, which will be able to directly avoid up to 3.5 million tons of CO2 through the use of hydrogen and renewable electricity after commissioning in 2027.