Austrian carbide and tool specialist Boehlerit, whose development expertise is based on close ties with the steel industry, is breaking new ground in the field of sawing and will be launching the intelligent and advanced machining solution in the form of the “Sawtec 2.0” tool system with interchangeable cutting edges from May 2020.

Saw blades are used worldwide in the metalworking industry to cut bars, blocks, tubes, rails and profiles. In most cases, the saw teeth are soldered, which results in a high effort and high costs for regrinding and logistics, especially for large saw diameters.

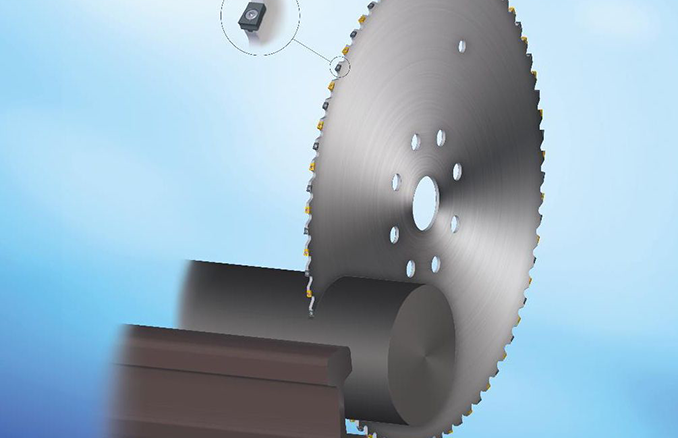

Boehlerit has reacted to this and developed the “SawTec 2.0” tool system, a solution for large saw blades with screwed, replaceable saw teeth. The screwed carbide saw teeth are very easy and quick to change on the SawTec 2.0 variant.

The patented “SawLock” attachment system guarantees stability, efficiency, precision and a high degree of flexibility. In addition, the right cutting edge for steel, stainless steel and high-temperature alloys can be selected from a range of available tooth geometries to suit the material being cut.

The starting range includes interchangeable teeth with 9 mm width in three cutting edge geometries (SP, SM, SS) and two cutting material grades (BCP40X and BCM40X), suitable for all common steel, stainless steel and high-temperature alloys.

With the most modern coated interchangeable cutting edges, the cutting areas can be increased by 200 percent with a higher cutting speed at the same time. The saw blades are available with diameters from 600 to 1500 mm, whereby the necessary bore for the spindle mounting is made according to customer requirements.