Shandong Weiqiao Light Metal enters a new business segment and orders a 28 MN direct extrusion and tube press from SMS.

Shandong Weiqiao Light Metal, a company of the Shandong Weiqiao Pioneering Group, has placed an order with the SMS Group for the supply of a 28 MN direct extrusion and tube press. With this investment in a multifunctional light metal extrusion press, the Chinese company is entering the new business field for extruded aluminium products.

The first extrusion press for Shandong Weiqiao is built at the site in Zouping City, Shandong Province, China. The product range will include both profiles and thin-walled tubes made of aluminum and aluminum alloys, which are mainly used in the automotive sector and in particular in the production of electric vehicles. The annual capacity of the extrusion press is around 10,000 tonnes per year.

“We are investing in an extrusion press that meets all our technological requirements. The flexibility in production as well as a high product variety offer our company a solid basis for the new business field. The extrusion technology of the SMS Group is the most advanced in its class and is also resource-saving,” says Zhang Guo, Technical Project Manager at Shandong Weiqiao Light Metal.

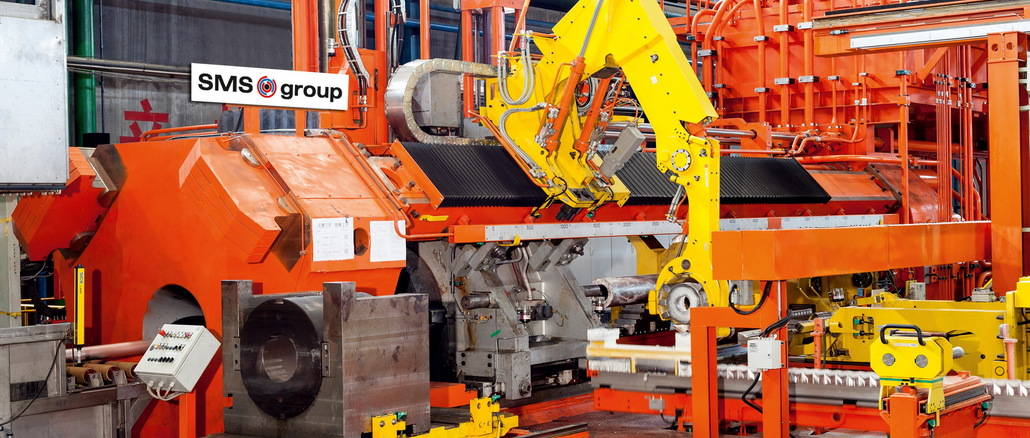

The extrusion press can process blocks with a maximum diameter of 254 millimeters (ten inches) and a maximum length of 1,200 millimeters. The fully automatic circulation of the loose press discs and the indirect dies is carried out by an auxiliary robot.

The SMS Group is building the extrusion press for Shandong Weiqiao according to a proven design with the patented lamella press frame, which makes the construction of the press noticeably stiffer and thus more resistant. The high-precision linear guides used are practically maintenance-free.

Thanks to the servo drive technology for all auxiliary functions and the EcoDraulic concept for reducing energy consumption, the press has a significantly more advantageous energy balance. All pumps not required during the pressing process are switched off by the automatic start-stop system. The modular technology and process control package of the SMS group offers further optimization possibilities. CadEX/3 (Computer Aided Direct Extrusion) for isothermal and isobaric direct extrusion calculates an optimum extrusion speed and block temperature for each profile type. This allows a higher surface quality and material structure of the profile to be achieved, which also significantly reduces the scrap rate.

The SMS software Picos documents all process and product relevant data which can be retrieved for certification purposes, for example for the automotive industry. With the integrated IBA measurement and analysis system, fault diagnostics can be performed remotely, reducing production downtime.

The SMS Group will supply the press to Zouping City in pre-assembled modules, which will significantly reduce the assembly time at the customer’s site. Acceptance of the new 28 MN direct indirect extrusion and pipe press is scheduled for the third quarter of 2022.

SMS Group is a group of internationally active companies in plant and mechanical engineering for the steel and non-ferrous metals industry. Around 14,000 employees worldwide generate sales of more than €2.9 billion. The sole owner of Holding SMS GmbH is the Weiss family foundation.

Web:

www.sms-group.com