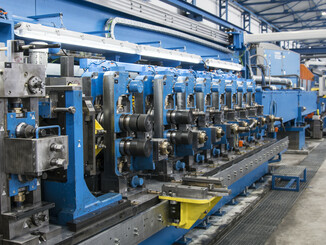

A pickling and galvanizing line with heat-to-coat technology was successfully commissioned by SMS in December 2020 in Ghent, Kentucky.

Following the successful commissioning phase, Nucor Steel Gallatin granted SMS Group final acceptance for the new “heat-to-coat” pickling and galvanizing line in Ghent, Kentucky, USA, in December 2020. SMS supplied the entire line, including engineering, process technology, furnace technology, pickling and galvanizing technology as well as electrics and automation.

© SMS Group

The line is designed for an annual production of 500,000 tons of pickled and galvanized hot-rolled strip. With a capacity of up to 180 tons per hour and a very wide dimensional range of the treated strip (up to 6.35 millimeters thick and 1,854 millimeters wide), it sets a new standard in the galvanizing of hot strip, says SMS.

During the commissioning phase last year, 70 percent of the planned capacity was already achieved. After this promising production result, there are many indications that Nucor will even be able to exceed the planned capacity in 2021.

The “Heat-to-Coat” technology for hot strip galvanizing is characterized by the compact, user-friendly U-shaped design, the turbulence pickling system, the powerful inductive heating system, the FOEN galvanizing technology and the Drever AfterPot cooling system.

Galvanized hot-rolled strip is used in a wide variety of applications, especially in the construction, transport and automotive industries, and also makes it possible to replace galvanized cold-rolled strip with hot-rolled strip.