With a new measuring method, Stainless Früchtl offers a service that is unparalleled anywhere in the world. The stainless steel trader can measure the straightness and roundness of bar stock with “previously unattained accuracy” (original statement) – and over a length of more than four metres. The logged values of the unique measuring machine are much finer and more accurate than the standard requires. This reduces not least the wear of turning tools.

“Due to our measurement results, our customers now have the certainty that the delivered goods also meet their requirements,” promises Wolfgang Sachsenmaier, Managing Director of Stainless Früchtl GmbH in Esslingen.

The stainless steel trader has developed a new measuring method that measures bar material much more comprehensively for straightness and roundness than was previously possible. The results are much more comprehensive, precise and meaningful than required by the standard.

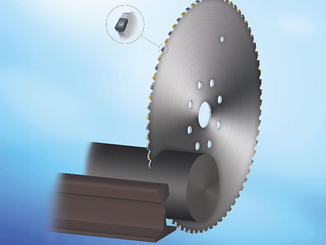

By means of radially rotating probe measurements, the system determines the straightness of bar material with diameters of three to 30 millimeters up to a length of four and a half meters with an accuracy of 0.1 mm per meter. In addition, the roundness is measured to deviation tolerances of 1 µm and the results are logged. The company developed and built this innovative measuring machine itself together with partners.

The fact that such measurement results are now available for the first time has also impressed a major customer in the pneumatics sector. Stainless Früchtl can thus prove that this customer receives the raw material for the production of its pneumatic cylinders in the quality that meets its standards and requirements.

The machine logs the results, and the Esslinger give the log with the goods to their customers.

They benefit from the tested bar material in several ways. For example, processors of the tested goods report increasing productivity in long turning processes on corresponding automatic machines. This is because the tool wears much less with straight rods than with rods that are out of balance. The downtimes increase drastically.

Surface measurements with long travels and spectral analyses within the scope of material testing complete the services with which Stainless Früchtl wants to convince customers also in the future.

Noble in the niche

Stainless Früchtl is a stainless steel trader founded in 1972 by Günther Früchtl in Esslingen am Neckar. The German and international customers come from the mechanical engineering, automotive, aerospace and, above all, medical technology sectors. The steel grades available as round, flat or square steel include around 30 types from 1.2316 to 3.7165 as well as the rarely available, highly corrosion-resistant stainless steel grade 1.4542. In the medical sector, many of the mostly world-renowned companies are long-standing customers. Since 2021, the Esslingen-based company has been certified according to the medical standard DIN EN ISO 13.485:2016 and is considered a system-relevant company. In 2016, the internationally important French Stainless group took over Früchtl as part of a succession plan. Most recently, Stainless Früchtl achieved annual sales of around twelve million euros.

Web:

www.fruechtl.gmbh