At Blechexpo, thyssenkrupp Steel (TKS) presented its new Perdur product brand for wear-resistant strip.

As a further member of the strip sheet family, the “perdur” product family is named after a combination of the terms performance and durability. According to the manufacturer, the particularly high wear resistance is characteristic of Perdur and makes it especially suitable for use in components subject to wear, such as tipping troughs for construction site vehicles or superstructures for refuse collection vehicles.

With Perdur 400 and Perdur 450, TKS offers versatile strip sheets that combine wear resistance with good processability. The special feature is the guaranteed toughness combined with the advantages of the strip sheet portfolio. Alloy concepts optimally matched to the thickness range with low carbon equivalent ensure good cutting and bending properties.

Coil production of the Perdur materials takes place in Duisburg, while the decoiling of the wear-resistant and high-strength strip is carried out in Belgium in the cut-to-length line of the thyssenkrupp subsidiary Heavy Plate Antwerp.

According to the manufacturer, customers who use Perdur also benefit from an expanded performance and service portfolio. Buyers of the material can therefore expect comprehensive customer support, including individual material advice and application and process optimisation geared to customer requirements.

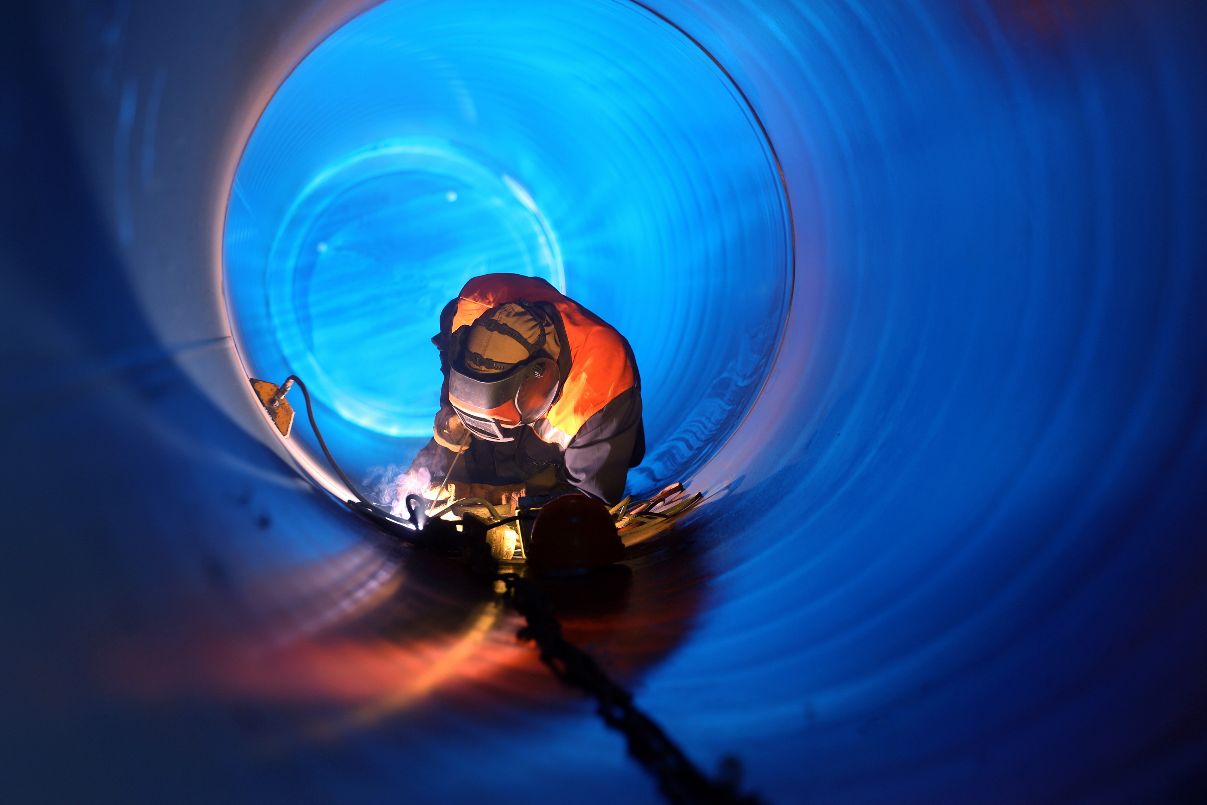

With Perdur the customer has the possibility to develop economically and at the same time ecologically sustainable vehicle models. Reasons: lower total own weight, good payload increase, fuel savings and economic cost reduction due to durable wear parts. Furthermore, with Perdur the steel manufacturer guarantees hardness and toughness as well as high surface quality, at the same time good cutting and welding properties and better formability.

Author:

Dietmar von der Au

Web:

www.thyssenkrupp.com