Spartanburg Steel Products Inc. in Spartanburg, South Carolina, USA, manufactures pressed metal parts, components and complex assemblies mainly for cars, trucks and agricultural machinery. Its customers include several well-known companies operating on the world market.

© AP&T

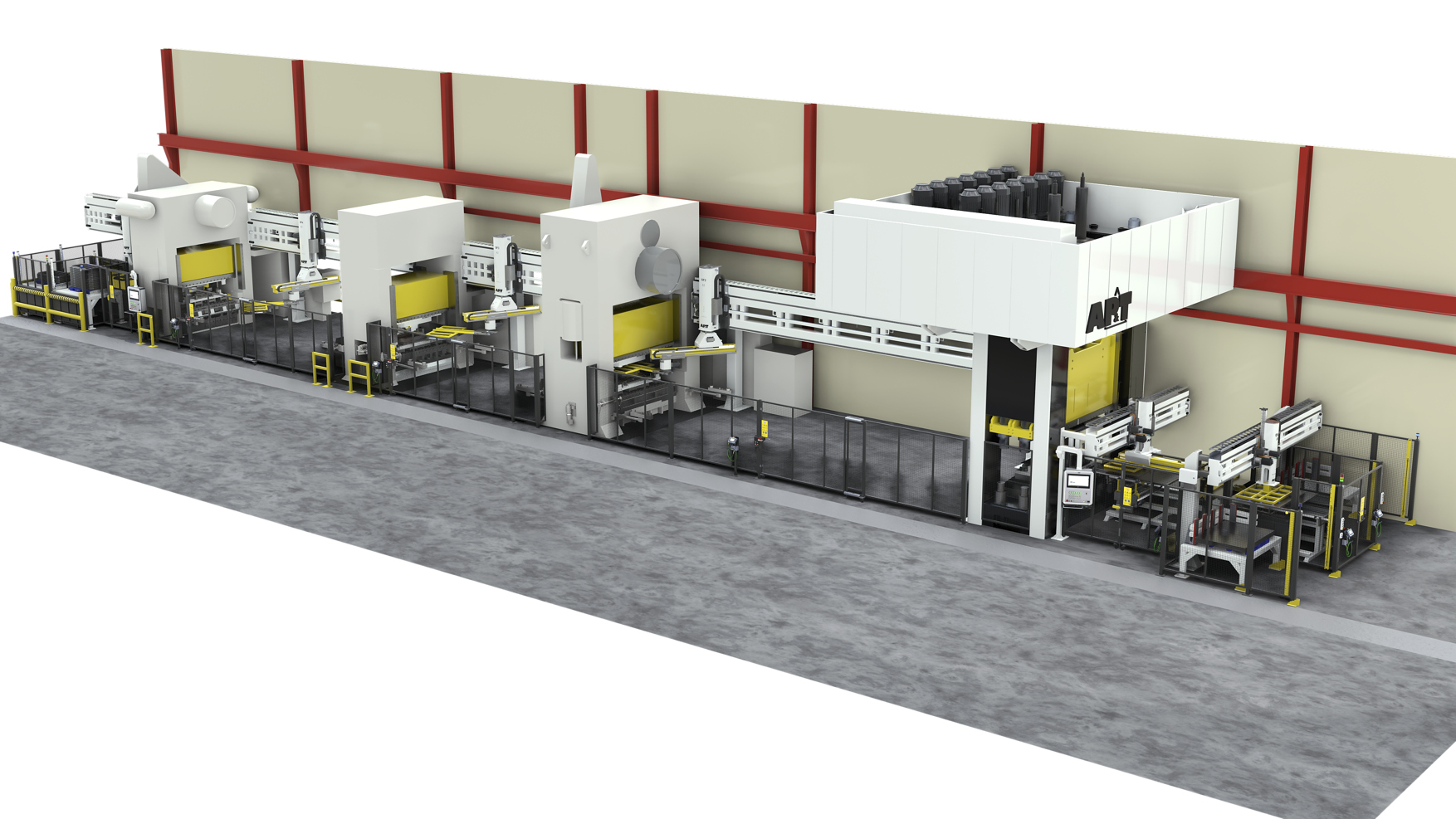

To improve safety, make manufacturing more efficient, reduce cycle times and increase flexibility, Spartanburg Steel decided in 2017 to automate one of its existing tandem lines of five large presses, which at the time were operated entirely manually. Because of its pre-existing relationship with AP&T North America, it was immediately clear who the company needed to turn to for a solution.

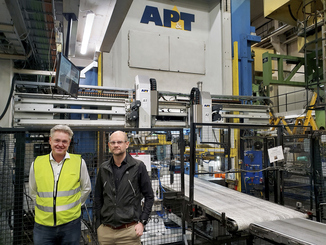

“This was our second automation from AP&T. We had previously purchased a transfer system that works very well to this day, so we had complete confidence in this technology,” says Chad Raynes, vice president of business development and engineering at Spartanburg Steel.

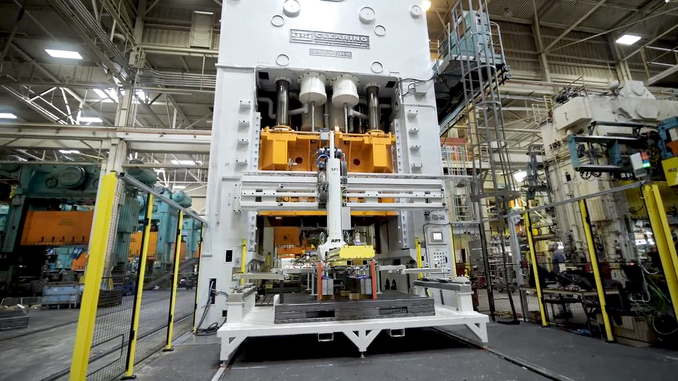

It was a technical challenge for AP&T to efficiently close the critical gap between the presses on the line. “Instead of using traditional industrial robots, we presented a solution based on our new generation five-axis SpeedFeeders,” explains Adam Allansson, President of AP&T North America.

The bid was extremely well received and in April 2018 Spartanburg Steel placed the order. A year and a half later, the equipment was installed and integrated, and the now fully automated line could be put into operation.

© AP&T

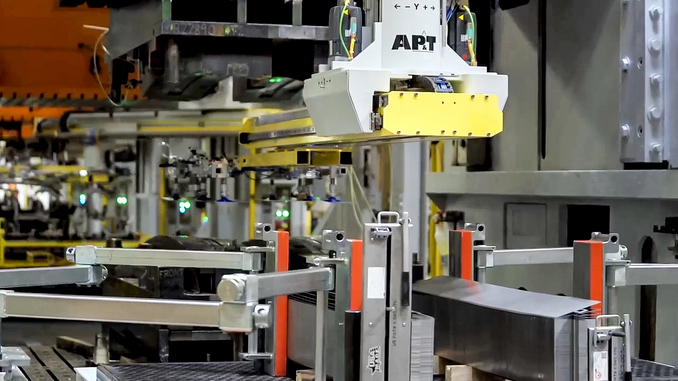

“In total, we installed six SpeedFeeders for blank feeding, part transfer between the five presses and output. During the time we were dedicated to our task, Spartanburg Steel performed an upgrade of the presses in the line and the die change system. We worked closely with other suppliers to ensure the best possible overall solution in the shortest possible time,” reports Adam Allansson.

Since fall 2019, the modernized tandem line with five presses has been operating in line with our expectations. It is regularly maintained by AP&T technicians, and new employees at Spartanburg Steel are trained by AP&T in operation and safety.

“We have implemented automation to improve safety when working on the line. This has also resulted in better efficiency at a lower cost. The line has fully met our expectations and continues to run well. We plan to automate more lines in the future, especially a tandem line in 2023,” concludes Chad Raynes.

Web:

aptgroup.com