Together with Gedia, AP&T has developed what is possibly the world’s most advanced production line for the manufacture of press-hardened components for the automotive industry. A real success story that proves that goal-oriented cooperation built on mutual trust can really achieve a lot.

© Gedia

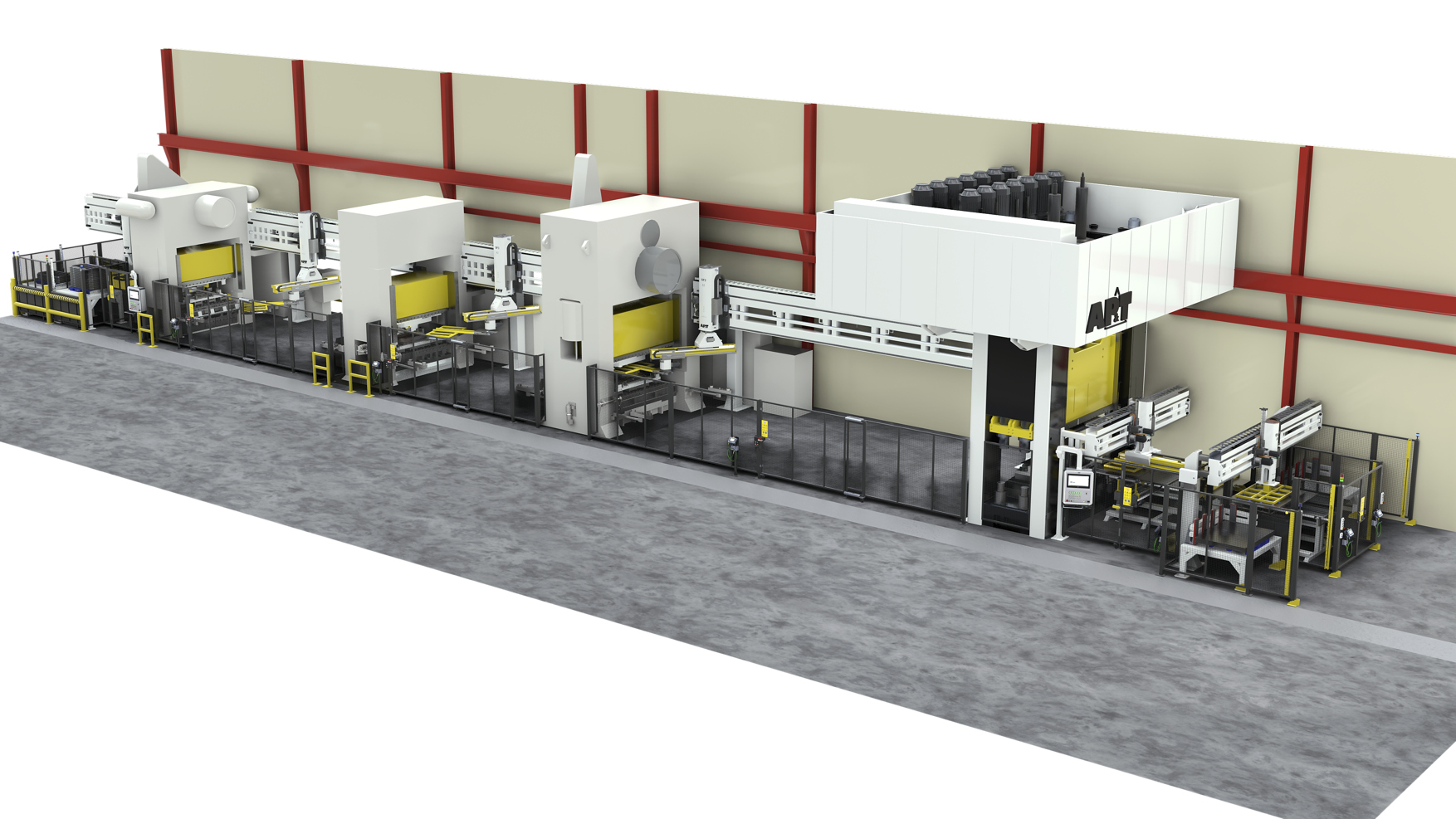

AP&T’s latest production solution for press hardening sets the stage for automotive manufacturers to offer lighter, safer and more flexible designs that are more cost and energy efficient The solution includes AP&T’s servo-hydraulic press, which offers a 70 percent reduction in energy consumption compared to conventional hydraulic presses, and the TemperBox, which allows soft and hard zones to be combined in the same finished part.

The first commercial production line using both innovations was commissioned at Gedia in Germany in the fall of 2019. Later, a system of the same type was also installed in the company’s plants in Spain and the USA. It is no coincidence that Gedia and AP&T are pioneering the future of press hardening in the industry. It is the result of a decade of deep-rooted collaboration between the two companies.

Gedia is based in Attendorn, Germany, and has been manufacturing pressed sheet metal parts for the automotive industry since the mid-1950s. In 2005, the company began to take a serious interest in the potential that press-hardening technology offered for producing structural components that combine strength and light weight – features that have enabled automakers to improve impact safety while reducing energy consumption and climate-changing emissions.

They explored the market and contacted AP&T, a pioneer in the development of production lines for press hardening. For many years, the two companies remained in sporadic contact, but without measurable results. That would not change until 2012, when AT&P received a request to negotiate from Gedia.

One order for three complete plants

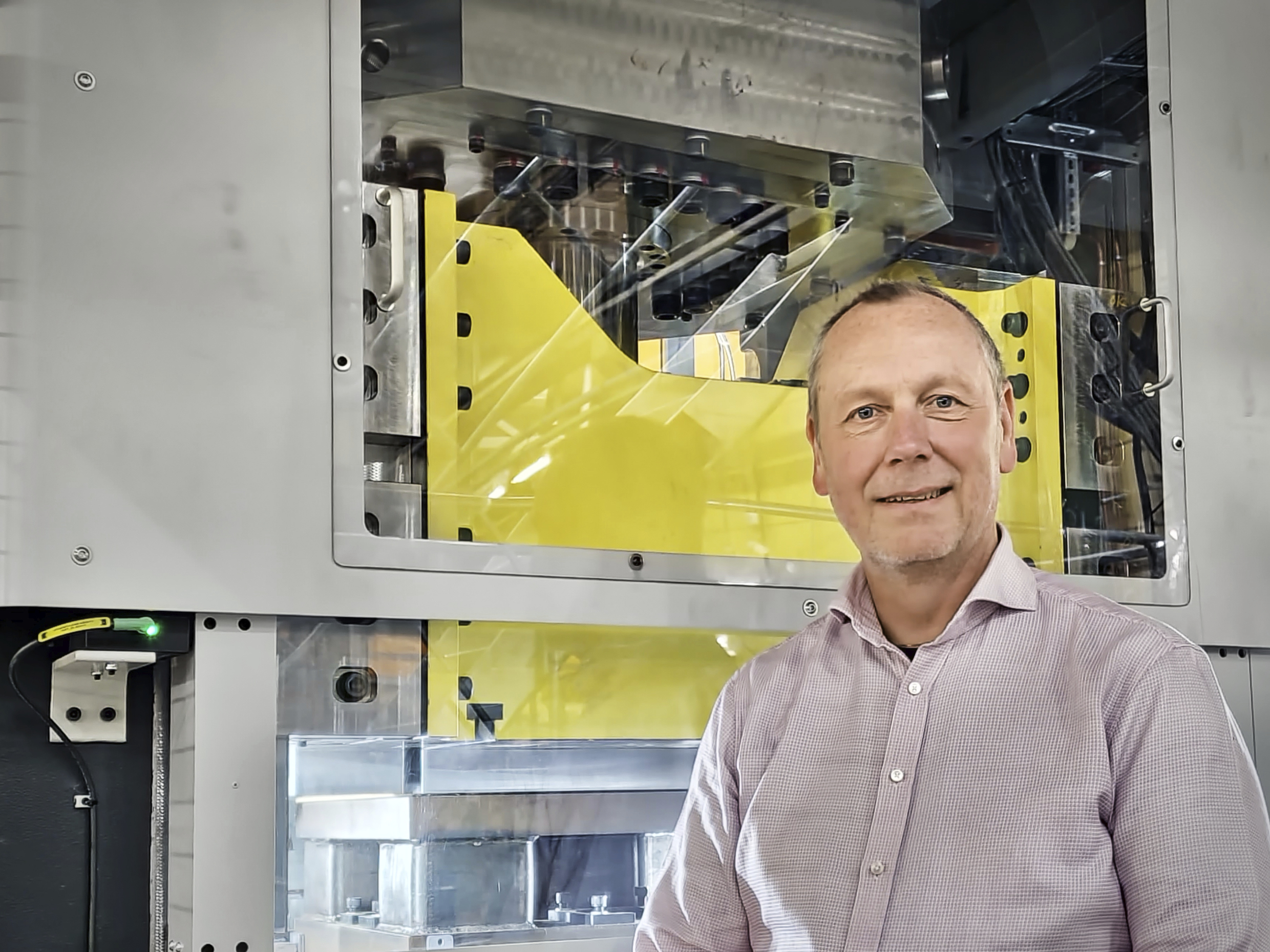

“We had the impression that Gedia was interested in a potential investment in their first press hardening line. After the meeting we had an order for three complete plants, a really positive surprise,” says Michael Hunter of AP&T, Managing Director and Head of Sales and Marketing Europe and Key Account Manager for Gedia.

The three plants were commissioned between 2014 and 2016, one in Attendorn and two at the company’s production facility in Nowa Sol, Poland.

“It was a technically challenging project that allowed us to gain useful experience and motivated us to continue developing and testing new press hardening technologies together in the future,” explains Hunger.

Burkhard Vogt, Group Director Engineering at Gedia, agrees: “It was an exciting project. We solved the problems together and achieved really good results. Our cooperation has developed and deepened, we have become closer, established new, useful contacts in different parts of the two companies.”

Industrialization of the TemperBox for partial press hardening

Let’s look back: In 2014 Gedia was looking for a partner for the commercialization and industrialization of a new, partial press hardening technology, the TemperBox; at that time still a prototype, and again the choice fell on AP&T.

“I contacted Kent Eriksson, AP&T’s sales manager, whom I had met while working with press hardening equipment. I wanted to find out how we could develop the TemperBox technology together,” says Vogt.

To turn this into a marketable product, the technology had to be tested under industrial conditions. After an initial test at AP&T in Ulricehamn, AP&T was commissioned to build a pilot plant with an integrated TemperBox for testing and small-scale production in Attendorn. The results were promising.

When Gedia received an order for partially press-hardened components from one of Germany’s leading automotive manufacturers, they needed an industrial-scale system for series production. It was the beginning of a highly interesting project that would push the boundaries of press hardening technology.

Based on the successful process and product development, we decided to design a plant for series production, with the TemperBox as an integral part of the plant. One requirement was that production had to continue without extending cycle times,” says Vogt.

Stephan Gante, Head of Machinery and Facility Management at Gedia, was responsible for the procurement of the new plant, and thus also for the detailed specifications. “We were faced with the challenge of not only producing a large number of components per hour, but also of installing the plant in our existing premises, which offer little space. The plant also had to be reliable and easy to maintain. In addition, it was very important to us that the solution be energy efficient with low installed power and low power consumption per unit produced,” he explains.

“We started planning the new line in August 2018 and set a goal to have it up and running by January 1, 2020,” said Jörgen Theander the project manager at AP&T.

© Gedia

Two innovations in one and the same plant

The biggest technological challenge was to combine two innovations, AP&T’s servo-hydraulic press and the TemperBox, in one line for a process that had never been used commercially before. Organizationally, it was not easy to assemble a suitably specialized project team with the necessary expertise and the right attitude to the project. When hired, automotive experience was a must, as well as the ability to listen and collaborate excellently.

“It was critical that everyone from the project team to R&D would really understand the expectations of our customers and their customers for the plant. The goal was to produce industrial-scale products with customized, repeatable properties with short cycle times, high equipment availability and optimized energy consumption. That’s exactly what we were aiming for,” says Theander.

To increase efficiency, Gedia also put together a project team with the relevant expertise, led by Björn Müller. Both teams were involved in the installation of the equipment in Nowa Sol, and were responsible for the work on the test facility in Attendorn.

“The positive experience I had already had working with AP&T was confirmed when we now embarked on a new project together. During this time, we developed a close and trusting relationship, thanks to which we were able to solve our tasks absolutely smoothly. Nothing was left to chance,” says Björn Müller.

Jörgen Theander also emphasizes the importance of close cooperation: “Throughout the project, we worked closely together and exchanged ideas regularly, often in person at Gedia in Germany. This made it much easier for us to uncover problems and solve them efficiently. We worked together like a big, close-knit team, with everyone pulling together.

The starting point of the project was the documentation of the existing production lines and the test plant installed in Attendorn. We discussed which design solutions had proven themselves and could be used in the new line, what needed to be improved and what needed to be replaced by the new technology. On the basis of this analysis, specifications were drawn up and we began to implement the new line. It was installed and commissioned at the production facility in Attendorn in the fall of 2019.

“Since this was the first industrial press hardening line of its kind, there was a need to remain present on site for some time afterwards to make sure everything was working properly, make small tweaks here and there, and solve any problems,” Theander explains.

Even before the first system was finally installed, AP&T received an order for an identical system for Gedia’s Spanish production facility, not far from Barcelona. Theander: “Right from the start, we were able to incorporate our experience from the first line into the work on the second. And just 17 months later, together with Gedia Germany, we were able to deliver an optimized solution for the Spanish line.”

In January 2020, Gedia ordered a third production line of this type. This time it was to be installed in the fall of 2021 at the plant in Dalton, Georgia, in the USA.

The most important thing is people

“Together with Gedia, we have developed what is possibly the world’s most advanced production line for the manufacture of press-hardened components for the automotive industry. Thanks to our cooperation, we were not only able to overcome the technological challenges and gain valuable experience, we were also able to meet the high expectations placed on us,” says Theander happily.

“Through our professional, trusting and future-oriented cooperation, we have jointly developed and implemented a new technology on an industrial level that is business-strategic. But,: The most important thing is the people They have to be on fire for the task, work well together, understand and trust each other. This description not only applies to our relationship with AP&T, but is also key to our successful efforts with TemperBox,” postulates Vogt.

How does the end result now compare to previous AP&T press hardening systems? First of all, the new equipment is much more energy efficient, mainly due to the fact that the servo-hydraulic press consumes up to 70 percent less energy than conventional hydraulic presses. The latest generation of multi-layer furnaces, which consume 40 percent less energy than their predecessors, also makes an important contribution here. In addition, the new equipment enables a 20 percent reduction in cycle time for certain products, leaving more time for production.

During the design process, the focus was on higher availability and reduced maintenance requirements. The multi-layer veneers presented the teams with quite a few challenges in this regard, but they were able to overcome them successfully. Now our cooperation continues with the attempt to significantly increase the annual production hours.

“We have also developed our own method of verifying CQI-9 process repeatability for furnaces, so this is now much faster than before. This creates room for valuable production time,” says Theander.

According to Stephan Gante, the original specifications were practically applied three times in a row. What does he say about the results? “We now have a user-friendly, space-saving solution with a high level of process reliability and excellent energy efficiency. In addition to the TemperBox itself, AP&T’s servo-hydraulic press, with its significantly lower cooling requirements and energy consumption per stroke compared to conventional hydraulic presses, plays a key role in the final result. We are extremely satisfied.”

Björn Müller is also satisfied. He reports that visitors are impressed and wide-eyed when they get their first glimpse of the new, highly automated lines He emphasizes that the development journey with AP&T will continue, “At each stage of this project, we have been able to gain new experience and insights that have taken us to the next phase. It’s a continuous improvement project that will continue.”

Perhaps the most important result, however, is the experience gained from working together in this way. Or in the words of Jörgen Theander: “Usually in many of our collaborations we talk about how we act as One Responsible Partner. In this joint effort, however, two responsible partners have together created a first-class solution thanks to their clearly formulated common goal, an open approach and their great commitment.”

Web:

aptgroup.com/en