Together with its agent Daekyung International, AP&T has built up a relationship with Simwon Co Ltd and MS Autotech Co Ltd in South Korea over many years. During a visit to China a few years ago, Simwon’s Managing Director had the opportunity to see AP&T’s press hardening production lines in action. This was the beginning of a rewarding collaboration between the two companies. AP&T’s first system was installed at the Simwon plant in Austin, Texas, in spring 2022. The output of the newly installed system has so far even exceeded the very high expectations.

© AP&T

Simwon is part of MS Autotech Co Ltd, a global supplier to many of the world’s largest car manufacturers. The group, which specializes in body parts, produces in South Korea, India, North America and China. Simwon America Corp. in Austin, Texas, produces press-hardened components for the American market. In the company’s production facility, we find AP&T’s new press hardening line.

“The new system will mainly be used to produce door frames for one of our larger American customers. To meet their requirements, the technology must function perfectly and we must be able to produce at top speed. The AP&T system exceeds our high expectations. The output is 15 to 20 percent higher than our other press hardening lines,” says Jeon Incheol, senior manager of the overseas sales team at Simwon Co Ltd.

The success of the Simwon investment is also important for AP&T. “We are naturally delighted to be able to meet Simwon’s high requirements in terms of product quality, cycle times and machine availability. For us, this is a strategically important deal that strengthens our position in the press hardening sector on the North American market,” says Peter Robisch, Sales Manager at AP&T.

Now that the plant has been in operation for almost a year and a half, both companies are open to discussing how they can intensify and further develop their collaboration. “In this context, it is a great advantage that we have well-established service, support, spare parts supply and sales organizations in the USA,” says Robisch.

More orders for equipment could be expected in the long term. No concrete decisions have yet been made, but as Incheol puts it: “Simwon has a good feeling.”

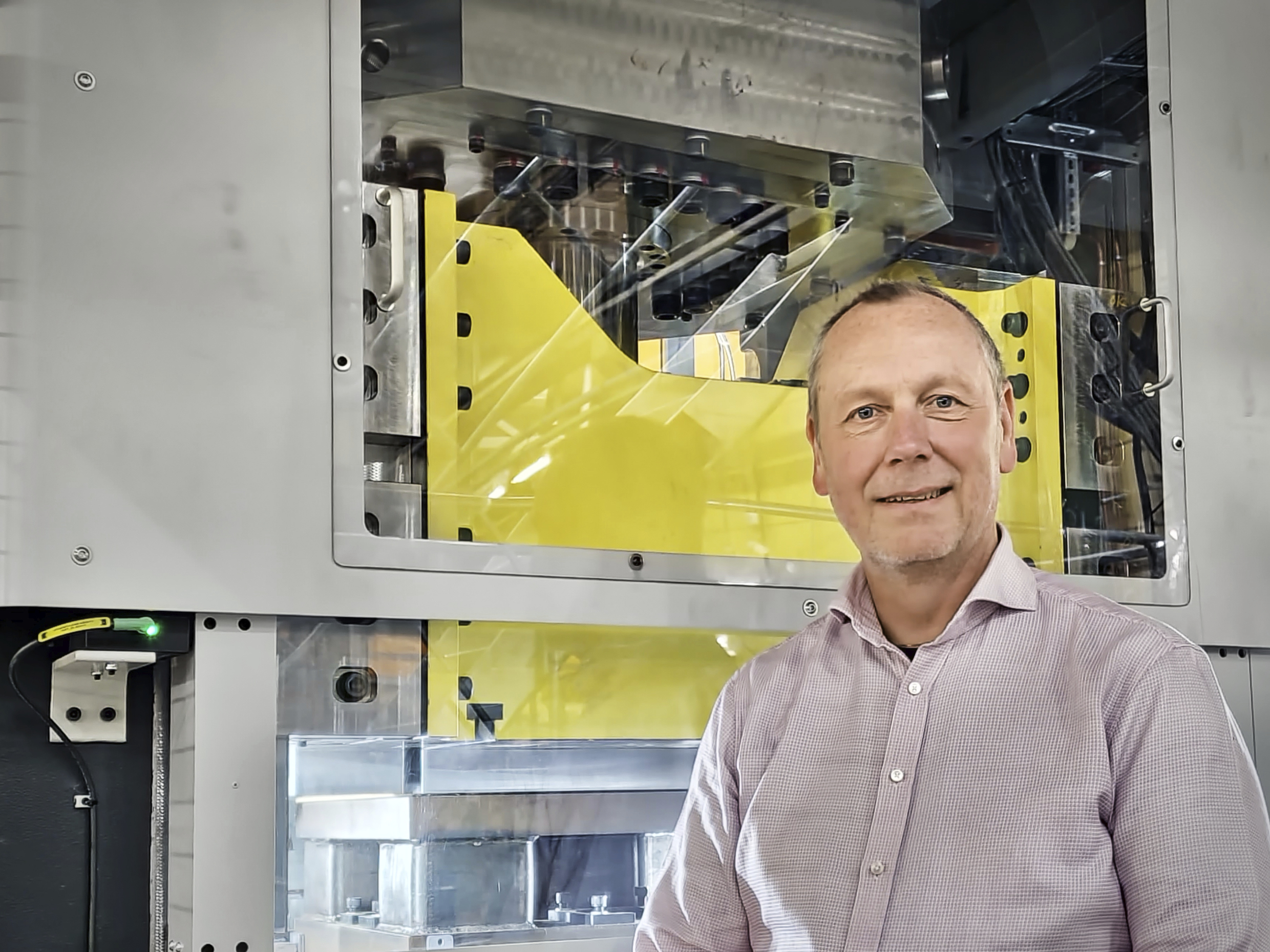

System solution based on the latest technology

In its role as One Responsible Partner, AP&T delivered a fully integrated, modular, state-of-the-art system solution in 2022. The system comprises a hydraulic press with a pressing force of 12,000 kN, automation equipment and a control system. Thanks to the uniform control system, the system’s hydraulic presses and linear robots can be synchronized, which enables an optimal process and short cycle times. The system is also equipped with inline process monitoring from AP&T. Their cameras and pyrometers ensure a well-controlled production process and a high, consistent quality of the parts produced.