Finding the right supplier for your projects is not always easy. However, Mersen did not have to look far, because the ideal partner for them was found directly in the region.

Particularly in the area of customer-specific machining, Mersen relies on the standard parts manufacturer Meusburger from Wolfurt in Vorarlberg. Its support is particularly helpful when things have to move quickly or when special requirements can no longer be optimally met in-house, for example in the case of extremely deep milling and fitting bores. In Meusburger they found the right partner. Thanks to its modern machinery, Meusburger can process all orders quickly, cost-effectively and in the required quality. This convinced Mersen right from the start.

The Mersen Group, founded in 1891, today has a remarkable 60 production plants in more than 35 countries with a total of 6,800 employees. Starting with process engineering, through electronics, energy and transport, to the chemical and pharmaceutical industries, the company covers a number of economic sectors. The main business focuses on corrosion-resistant graphite-based equipment, carbon brushes for industrial electric motors, insulating graphite for high-temperature applications and industrial fuses.

At the site in Hittisau, Austria, which has been in existence since 1972, around 160 employees work on the development and design of customer-specific components. Especially the high vertical range of manufacture distinguishes Mersen. Whether it is punching, gravity die casting, injection moulding or plastic presses, Meusburger can provide the best possible support with its wide-ranging and perfectly matched product range.

The fact that Mersen can obtain all the steel grades it needs from a single source is a decisive advantage. “The extensive range is a big plus, because all our requirements are covered by one supplier. We not only purchase custom machining and steel, but also e-parts and workshop supplies from Meusburger,” says Joachim Dorner, design engineer at Mersen.

Mersen is also satisfied with the constant availability and high quality of the products from the supplier. With the large warehouse, the standard parts manufacturer was able to score points with Mersen right from the start. “When things have to move quickly, Meusburger is always there. We are glad to have a partner here that we can rely on at all times,” says Mr Dorner happily.

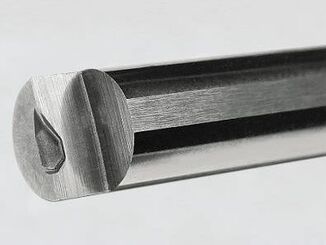

The cooperation between the two companies already has a long history. This may be due to the fact that Meusburger is well known in the region, especially for its all-round service and stress-relieved annealed steel. Even with complex requirements, Meusburger can convince with the best quality in customer-specific processing. Mr. Dorner emphasizes, “The quality of the column drilling is extremely high, no other supplier comes into question for us here.”

For Joachim Dorner, there is another reason for the many years of cooperation: the good teamwork. With Peter Nußbaumer, the head of the Machining Business Unit, Joachim Dorner has an ideal contact person here. And not only that – Meusburger’s online tools have also completely convinced Mersen. “Working with the color table standard eliminates the need for 2D drawings for the design departments. This saves us a lot of time. The clear website and especially the ‘technology tips’, which can always be found online at Meusburger, often help us enormously. Furthermore, all orders are always handled professionally and to our complete satisfaction; we feel we are in very good hands here,” praises the designer from Mersen.

The fast service, the “you” culture and the consistency of the contact persons is what makes Meusburger stand out in the long-standing cooperation. So Peter Nußbaumer and Joachim Dorner do not only speak the same language in one respect.

Web:

www.meusburger.com