Thyssenkrupp Automation Engineering, Andritz Soutec and Schuler Pressen joined forces in a cooperation agreement to offer integrated production lines for the high-volume manufacture of metallic bipolar plates. Customers benefit from receiving everything from a single source. In addition, solutions for the production of the membrane electrode assembly (MEA) as well as for the stack and system assembly of fuel cells including testing technology can be supplied. This covers the entire value chain for the production, assembly and testing of a fuel cell.

The bipolar plate production facilities are scalable and designed for a capacity of 50,000 stacks per year, with approximately 300 to 400 bipolar plates per stack. This requires an output of around one bipolar plate per second.

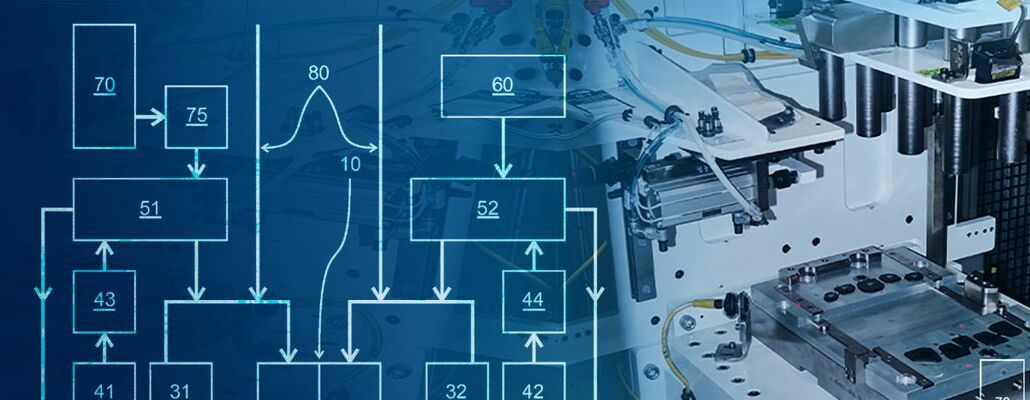

The process is divided into several steps:

– precise forming of stainless steel sheets for the production of monopolar plates

– Welding to bipolar plates

– Quality and leak test

– Highly accurate application of the seals

These procedures are followed by the stacking process.

Both bipolar halves in one press stroke

The first process step of the production line is the forming technology for stamping and trimming bipolar plate halves made of 70 to 100 µm thick stainless steel sheet. Schuler offers mechanical and servomechanical knuckle-joint presses with press forces of up to 20,000 kN for this purpose. The innovative “IntraTrans” transfer system enables the simultaneous production of both bipolar plate halves – anode and cathode – in one press stroke.

The material is fed from both sides of the press and transported through the individual die stations to the centre of the press. In addition, the bipolar plate halves can be brought together in the press and pre-joined by means of a spot welding process so that the position of both halves in relation to each other is fixed.

Laser welding, testing, seal application

In the subsequent process step, the bipolar plates are precisely welded gas-tight using remote laser welding. For this purpose, Andritz Soutec offers continuously operating laser welding systems in which the bipolar plates are welded by means of several laser beam sources operating in parallel. A subsequent leak test of the bipolar plates guarantees a constant quality.

Subsequently, a seal is applied with high precision to both sides of the bipolar plates by means of dispenser stations in systems from thyssenkrupp Automation Engineering, dried and visually checked for correct quality. In addition to an innovative system for transporting the bipolar plates between the plant sections, thyssenkrupp offers equipment for producing the MEA and for stacking MEA and bipolar plates to form the final fuel cell stack, including testing technology.

In addition, a comprehensive track & trace system enables the traceability of the individual bipolar plates starting from the coil material as well as all other production data of a fuel cell assembly.

Capacity 50,000 stacks per anno

“With this cooperation, our customers can for the first time obtain an integrated complete line for a capacity of 50,000 stacks per year with coordinated interfaces for the production of fuel cells,” clarifies Schuler managing director Frank Klingemann. Michael Menneking, CEO of thyssenkrupp Automation Engineering, is also convinced: “The companies complement each other ideally, and our international orientation means we are ideally equipped for this future technology.”

Web:

www.schulergroup.com