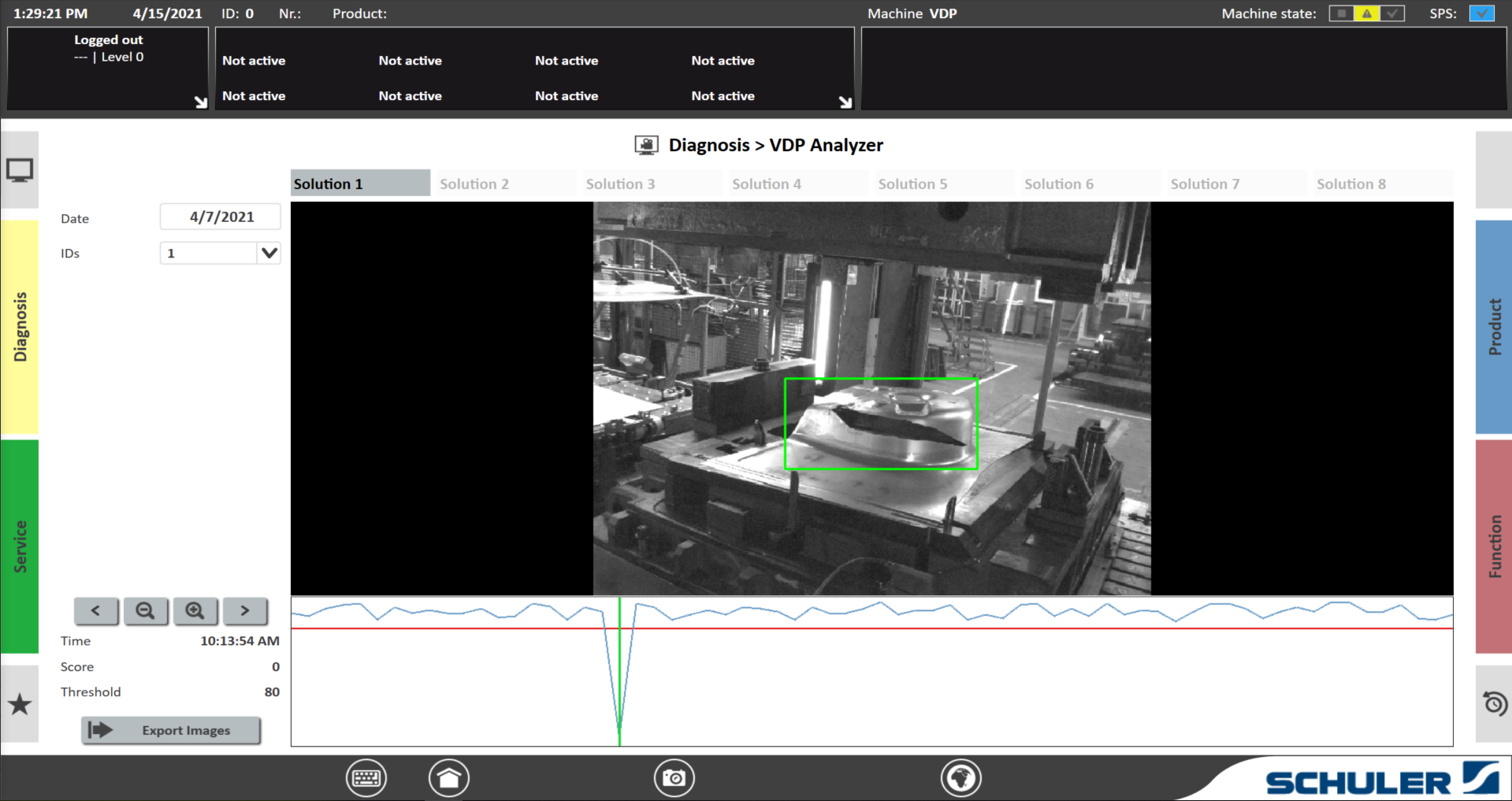

In 2019, Schuler developed a camera-based die monitoring system for presses under the name “Visual Die Protection” (VDP). The system is part of the “Digital Suite” in which Schuler has brought together its solutions for networking forming technology. VDP detects foreign objects or other sources of danger in real time and stops the system before any damage occurs. With the “VDP Analyzer”, Schuler is now presenting a further development that can also be used to get to the bottom of the causes of faults.

“In the visualization, it is possible to quickly gain an overview of exactly when deviations from the normal state have occurred based on deflections in the time curve,” explains Chief Digital Officer Rohitashwa Pant. “The user can now retrieve the images associated with these points in time in a targeted manner and see from them that, for example, parts are lying on a centering pin and are not threaded, or that punching waste keeps piling up in a particular scrap chute.”

This allows appropriate changes to be made to avoid future production interruptions, thus increasing process stability and ultimately output. The system also allows the export of the time series and image data for documentation and later comparisons.

“Our customers expressed a desire to also be able to look into the past with VDP to document errors and identify root causes,” explains Michael Werbs, Director of Edge Solutions. “With conventional cameras, press operators can have the die room monitored, but then have to laboriously evaluate the videos themselves afterwards. The VDP Analyzer takes this work off our customers’ hands.”

Web:

www.schulergroup.com