Volkswagen has officially commissioned the expansion of its press shop at the Zwickau e-car plant. From now on, the complete outer skin for the six electric models manufactured in Zwickau will be pressed on site. The investment of 74 million euros will help to further improve the CO2 balance of ID.3 and ID.4. The effect is considerable: More than 9,000 direct truck journeys for the body shop and thus 5,800 tons of CO2 will be saved annually from now on. This will create 60 new jobs at the factory.

Dr. Christian Vollmer, Member of the Board of Management for Production and Logistics at the Volkswagen brand, said at the ceremony in Zwickau: “Like Zwickau, all MEB locations in Europe will have carbon-neutral production. Zwickau is a pioneer and role model in this respect. And the new press plant is an important milestone on our “Way to Zero”, because by 2025 we want to reduce the environmental impact of our production – including energy use, CO2 emissions, waste and the use of water – by 45 percent per vehicle compared with the base year 2010. Already, 90 percent of all Volkswagen Passenger Cars brand locations obtain electricity from renewable sources. Production is consistently reducing emissions in all factories and logistics with its Zero Impact Factory environmental program.”

Michael Kretschmer, Minister President of the Free State of Saxony: “Saxony is the engine for electromobility. With its future-oriented and holistic approach, the Volkswagen vehicle plant in Zwickau is already playing a pioneering role worldwide. The new press plant is a clear commitment by Volkswagen to Zwickau as a traditional automotive location. The complete pressing of all body parts on site makes an important contribution to climate protection and relieves the environment through significantly fewer delivery trips.”

© Volkswagen AG

Jens Rothe, Chairman of the General Works Council of Volkswagen Saxony: “As the Works Council, we are particularly pleased that all 60 newly created jobs have been filled through the further qualification of our colleagues. This is an important signal: the switch to electromobility provides the Zwickau plant with good capacity utilization and secures jobs in the long term.”

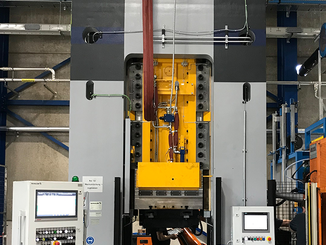

At EUR 74 million, the expansion of the press shop is one of the largest single investments in the transformation of the site. In addition to a Schuler XL press, an automatic stacking line and a 30-meter high high-bay warehouse for logistics have been put into operation on an additional area of 8,400 square meters. The costs for the high-bay warehouse alone amounted to 23 million euros. From now on, all the necessary outer body parts, such as doors and tailgates, for the electric models produced in Zwickau can be pressed on site. The former delivery from other locations such as Emden and Wolfsburg is no longer necessary. As a result, more than 9,000 truck journeys and 5,800 tonnes of CO2 are avoided each year – this corresponds to 16 percent of the direct truck volume for body construction at the Zwickau plant.

The centerpiece of the expansion is the new XL press from Schuler, which weighs more than 1,000 tons. It is considered one of the most modern presses in the automotive industry worldwide. Its pressing force is 69,000 kilonewtons, divided into five stages. With 10,800 press strokes per day, the 92-meter-long, 22-meter-wide and 12-meter-high press is very efficient. A decisive reason for this is the drive. For the first time, the Volkswagen Group is relying on a mix of conventional and servo technology within one press. Thus, the advantages of both techniques are combined in Zwickau: Due to the high speed, many parts are pressed, on the other hand, the highest quality is ensured by the very precise work.

Volkswagen brand’s second largest press plant is in Zwickau

After the main plant in Wolfsburg, the Zwickau vehicle plant now has the second largest press shop within the Volkswagen brand. On average, around 20 million parts per year have been produced in western Saxony over the past ten years.

The new XL press will increase output to up to 30 million parts per year by early 2022, some of which will still be supplied to other Group sites.

Transformation of the site will be completed in 2021

Zwickau plays a key role in the system change towards e-mobility: for the first time, a large car factory is being completely converted to electric mobility with investments of around 1.2 billion euros. All renovations will be completed on schedule this year.

The conversion of the plant has been taking place gradually and during ongoing operations since 2018. Since then, the body shop, paint shop and infrastructure have been extensively modernised and renewed. Among other things, the entire conveyor system had to be prepared for the electric cars. In addition, both production lines were converted in assembly.

With now around 1,700 robots in body construction and assembly, driverless transport systems and fully automated production processes, Zwickau shows what forward-looking volume production of electric cars looks like today.

“Way to Zero”: Volkswagen on the road to CO2 neutrality

With the “Way to Zero”, the brand has a master plan for zero-emission mobility for all. The starting point for this was the market launch of the ID.3 in 2020. This year is marked by the global roll-out of the MEB-based world car: the ID.4. In the coming years, Volkswagen will offer zero-emission mobility in all segments with the ID. family. By 2025, the brand aims to build at least 1.5 million e-cars per year and reduce its carbon footprint by 30 percent. By 2050, the goal is to be completely CO2-free – in products and as a company.

Web:

www.schulergroup.com