Dutch metal processor Dulasta has invested in a 15 kW laser cutting system. This has enabled the company to significantly increase its productivity.

Microstep Europe GmbH

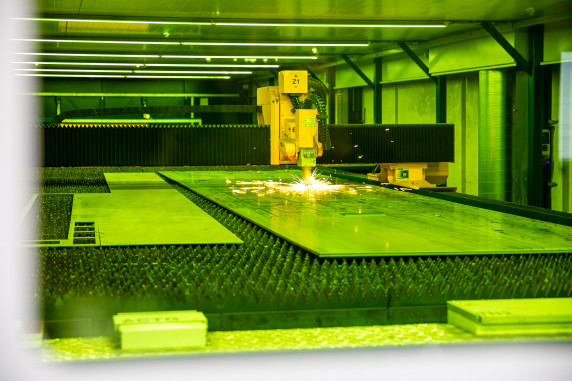

The family business Dulasta Metaalbewerking B.V. has specialized in the processing of sheet steel and the welding of complex components for over 35 years. As a supplier of everything from small to particularly large formats, the sheet metal processor supplies numerous branches of industry. To ensure precision and efficiency, Dulasta continuously invests in modern technology, including a new MSF Pro laser cutting system from Microstep. This machine is used for weld seam preparation and increases productivity through automated loading and unloading.

Klaas Dunnink founded the company in 1987 as a one-man business based in Staphorst, a Dutch municipality around 100 km from Amsterdam. Under the management of his sons Harm and Bennie Dunnink, Dulasta has developed into a family business in the metalworking sector. As the Dutch market leader in sheet metal processing from small to XXL formats and in the production of robot-welded components and assemblies, Dulasta supplies customers from various sectors: Construction and infrastructure, crane and mechanical engineering, offshore, oil, gas and wind energy, recycling, shipbuilding and transportation and logistics.

Machines for cutting large sheet metal parts

A central concern of the company is to invest in machinery and employee training. Dulasta focuses on digitalization and automation and always uses the latest production technology. A plasma cutting system from Microstep’s MG series with a length of 27 m is already in use. However, in certain cases – such as particularly precise welding edges – dimensional accuracy and surface quality are required. This is why the company started looking for another system. “We quickly realized that we were looking for a laser cutting machine. Our search ultimately led us to three options. One of them was the MSF Pro from Microstep, equipped with a laser rotator and a 15 kW N-Light CFX fiber laser,” reports Production Manager René Mulder.

Microstep Europe GmbH

Laser cutting system with 16,000 × 3,000 mm processing area

The laser rotator enables weld seam preparation up to 45°. In combination with the 15 kW fiber laser source, the system can process sheet metal up to a thickness of 25 mm. “It is quite a unique machine given its size of 16,000 m × 3,000 mm. Therefore, the machine has not yet been extensively tested or tried. Since we have already purchased other Microstep machines and have been working with Wouters Cutting & Welding, Microstep dealer in the Benelux, for 15 years, we had confidence in this machine. After a number of extensive demonstrations, we once again opted for our trusted supplier,” says Mulder. The machine is also equipped with a Microstep shuttle table for automated loading and unloading – which reduces downtime and increases productivity.

Satisfied with the investment

“Depending on the material to be cut, we have to adjust the machine differently. This is sometimes a little time-consuming, but with the help of Wouters everything runs smoothly. Without the MSF Pro, we would have to outsource this type of cutting work. Of course, we would prefer to avoid this, as it would drive up costs for the end customer and we would have to outsource production. We are therefore glad that we decided to invest in our own laser cutting machine,” concludes Mulder.

Web:

www.microstep.com