Bernd Siegmund GmbH presented its latest solutions for welding technology and automation at Automatica 2025 in Munich. In Hall A5, Stand 409, visitors can expect a selection of products, technologies and live demonstrations on the subject of precise clamping, welding and automation.

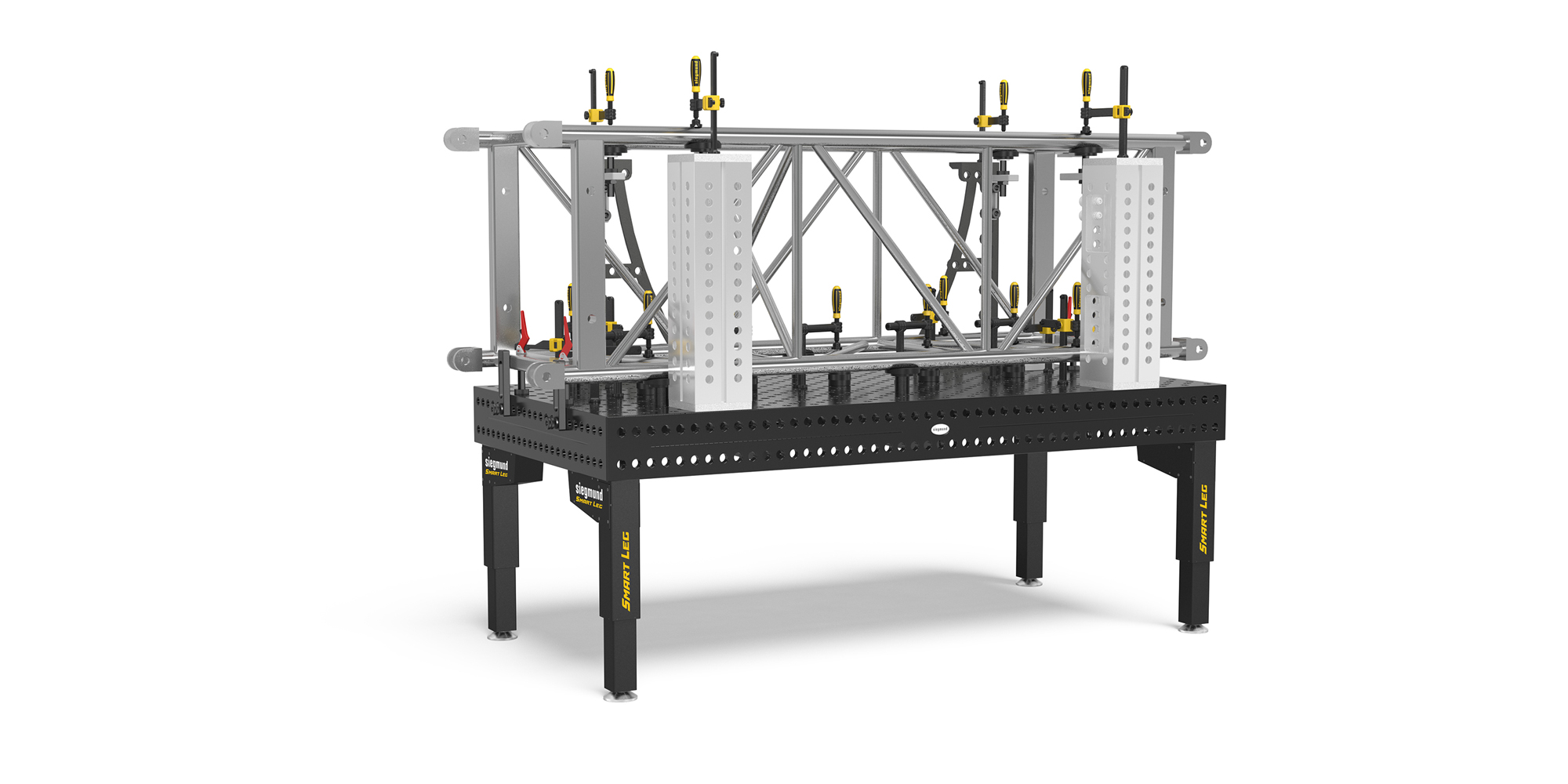

The Siegmund welding tables – used over 100,000 times worldwide as tools for industry, trade and automation – are at the center of the trade fair presentation. The welding tables owe their durability and resistance to the standardized plasma nitriding in combination with the tool steel grades X8.7 and X8.8 specially developed by Siegmund. The trade fair exhibits show a variety of superstructures, application possibilities and adaptations – especially for automated manufacturing processes.

Experience live: Lift table and Roto positioner

A Siegmund lifting table and a Roto positioner will also be on display at Automatica. Practical examples – including a motorcycle frame and a turbine wheel – will be used to illustrate various assembly situations. The lifting table enables the stepless and ergonomic height adjustment of heavy workpieces, ensuring comfortable and safe working. The Roto positioner allows precise turning and tilting movements of components – a suitable solution for automated production processes.

Live welding with cobot and cold wire system

One of the trade fair highlights is the live demonstration of a robotic welding cell with cobot, welding system and cold wire feeder. Visitors can experience the simple operation and high efficiency of modern automated welding solutions in real time.

Automation with seam tracking and CAD integration

A cobot robot with a seam tracking sensor will be presented on a mobile workbench with castors. The intuitive software operation, simple teaching and the use of a scanner for CAD data creation will be demonstrated: even without an existing CAD model, a 3D scan can be used to generate a point cloud, a mesh and an edge model – right down to the selection of the welding edge at the touch of a finger on the touchscreen.

Automated welding in interaction

Siegmund also impressively demonstrates how seamlessly integrated automation solutions can be implemented on a Siegmund welding table using a practical application example. The focus is on an alternating operation in which cobots and welding turntables work together to carry out automated welding processes. The welding turntables can be smoothly integrated into the overall system via suitable interfaces and precisely controlled – convincing proof of the efficiency and flexibility of modern automation concepts.

New modular laser welding cell

Safety and innovation are also the focus of the new modular laser welding cell. The cell offers protection against scattered radiation and reflections that can occur when working with lasers. Thanks to its innovative design and pre-assembled side panels, it is quickly ready for use. The laser welding cell is suitable for manual laser welding and laser cleaning in the wavelength range from 940 to 1090 nm. Siegmund offers a comprehensive safety concept and presents a cell that has been specially developed for demanding industrial applications.

Background

Bernd Siegmund GmbH is an owner-managed family business with over 30 years of history. With five locations across Europe and a sales network in over 60 countries, the company has a global presence. Two application highlights are, for example, the use of Siegmund welding tables in the rocket construction of the aerospace company SpaceX or for repair work in the White House in Washington D.C. The Siegmund welding and clamping tables are based on a flexible modular system and, in addition to machine, plant, metal and vehicle construction, are particularly in demand in prototype construction and series production with and without robot connection.

Web:

www.siegmund.com