Siegmund presents the next generation of laser welding cells: the Siegmund modular laser welding cell. It combines high safety standards with fast commissioning and a modular design that offers great flexibility.

According to the manufacturer, the Siegmund laser welding cell reliably protects against scattered radiation and reflections that can occur during laser welding. Thanks to the pre-assembled side walls, the cell is quickly ready for use. It is suitable for hand-held laser welding and laser cleaning in the wavelength range from 940 to 1090 nm and offers the following features:

– Maximum safety thanks to reliable protection against scattered radiation and reflections

– Quick commissioning thanks to pre-assembled side panels

– Suitable for a maximum laser power of 3 kW

– Spacious work area with extra-wide double door (2370×2240 mm)

– CE-compliant (safety component) and certified in accordance with DIN EN 60825-4

Manual laser welding has established itself as an essential process in welding technology. Siegmund introduced a laser welding cell as a protective housing back in 2023. Now the company is setting new standards in safety and flexibility with the new modular generation.

The laser welding cell from the Augsburg area is characterized by a variety of configuration options and can be expanded with additional wall elements. This means that each cell can be individually customized. It also meets the highest safety standards and is both CE-compliant and certified in accordance with DIN EN 60825-4.

The advantages of the Siegmund laser welding cell:

– Certified and secure

– High-quality individual components

– Freely positionable door

– Can be extended at any time

– Individually configurable

– Special solutions on request

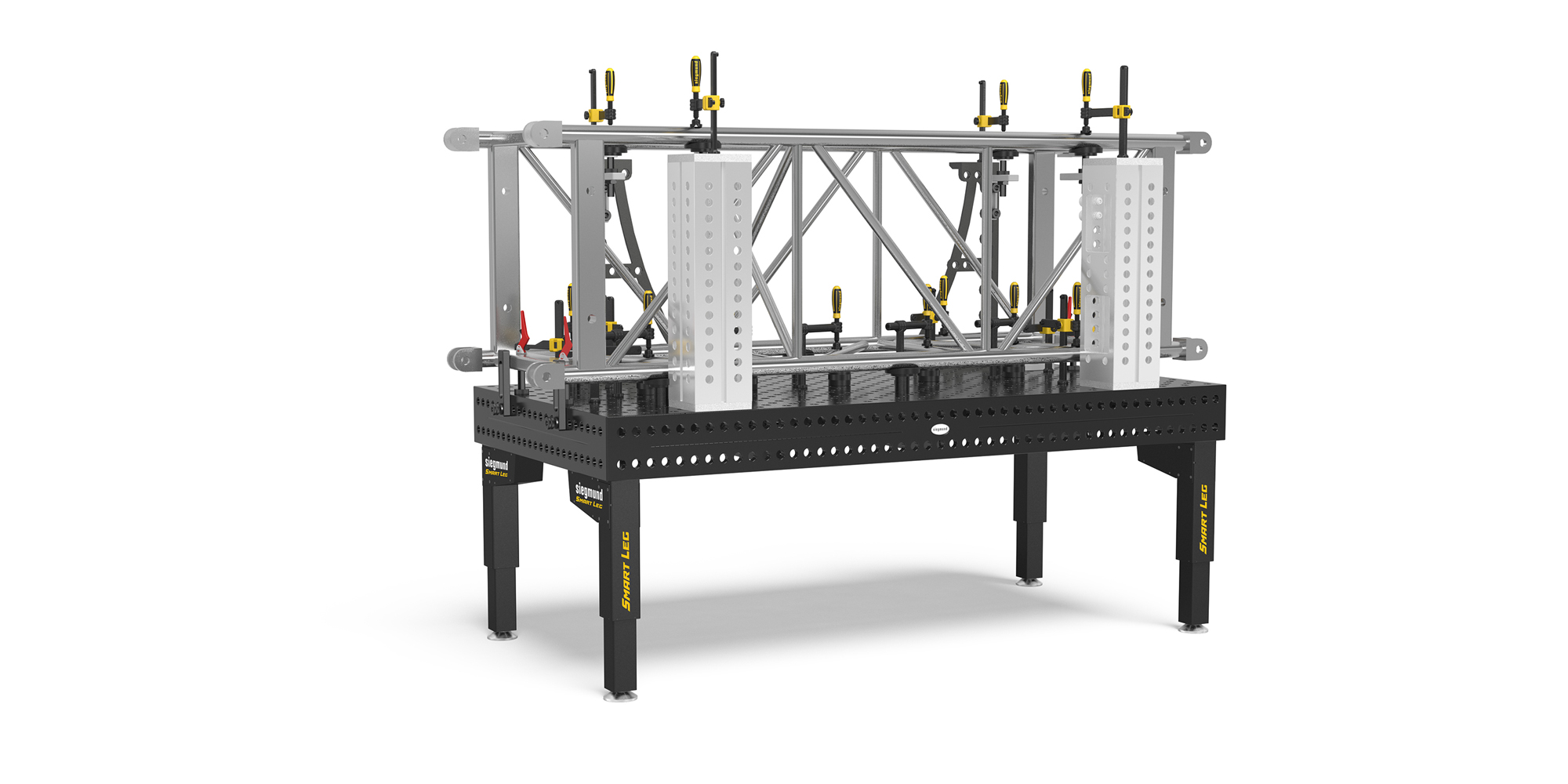

To match the new laser welding cell, Siegmund offers precise welding and clamping tables that stand for quality, resilience and precision. The exclusive welding tables made of X8.7 and X8.8 tool steel impress with their exceptional hardness, high impact resistance and long service life. Advantages of Siegmund welding tables:

– Low-wear and durable surfaces thanks to plasma nitriding

– Safe holding of workpieces during machining

– No welding distortion

– High precision and repeat accuracy

– Versatile clamping options thanks to drill holes

The Siegmund workbench combines the stability of a classic workbench with the advantages of welding tables. Plasma-nitrided, high-precision steel plates ensure durability, resilience and a scratch-resistant, corrosion-resistant surface. Features of the Siegmund workbench:

– Sturdy frame made of aluminum profiles in the exclusive Siegmund Wave design

– Low-wear and durable surfaces

– Flexibility thanks to hole grid

– Individually expandable

Background

Bernd Siegmund GmbH is an owner-managed family business with over 30 years of history. With five locations across Europe and a sales network in over 60 countries, the company has a global presence. Among other things, Siegmund welding tables are used in rocket construction by the aerospace company SpaceX or for repair work in the White House in Washington D.C.. The welding and clamping table systems are based on a flexible modular system and, in addition to machine, plant, metal and vehicle construction, are particularly in demand in prototype construction and series production with and without robot connection.