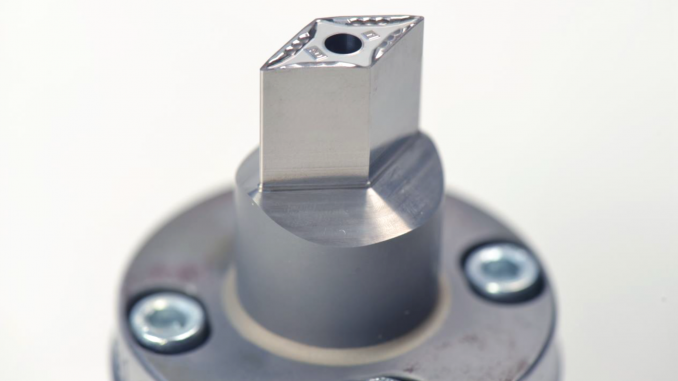

Tools made of hard materials and ceramics such as tungsten carbide are particularly wear-resistant. However, the tools used to manufacture them wear all the faster – unless the tool is light. Researchers at the Fraunhofer ILT have now developed a process chain in which the shaping and polishing of hard material components can be implemented with an ultrashort pulse (USP) laser without changing the clamping.

Drills, milling heads, rollers or even punching inserts made of ceramic hard materials not only have bite, but also last significantly longer. However, while their wear resistance has a positive effect on tool life in production, it is also problematic in the manufacture of these tools. This is because the tools used for shaping and surface treatment bite their teeth out on the mixed carbide carbides, cermets and ceramics used here. Wear is correspondingly high when manufacturers rely on mechanical machining processes.

© Fraunhofer ILT

UKP lasers work where mechanical processes reach their limits

This is different with ultrashort laser pulses. Even commercially available USP lasers with 20 to 40 watts of power are capable of efficiently removing the hard materials used in toolmaking. Where their high-energy pulses, which are just a few picoseconds long, hit the surface, the material vaporizes. As this happens at frequencies in the Mhz range, the laser material removal achieves area rates of up to 100 cm² per minute.

However, the potential of USP processing is not exhausted with this shaping evaporation of the materials. Researchers at the Fraunhofer Institute for Laser Technology ILT in Aachen have developed a process chain in which the same USP laser performs both the shaping material removal and the subsequent polishing of the tool surfaces.

“The USP laser is a universal tool with which we can carry out different processing steps, sometimes in the same clamping,” explains Sönke Vogel, team leader of 3D structure ablation at Fraunhofer ILT, who has driven the process forward together with Astrid Saßmannshausen, team leader of structuring transparent materials.

The key to linking the process steps lies in the parameterization of the laser: while the material is removed with high pulse energy and a low repetition rate, the opposite is true for polishing. The USP laser applies energy to the surface of the workpiece with a pulse frequency of up to 50 MHz, which accumulates there and melts the uppermost 0.2 to 2 micrometers.

The material does not evaporate, but forms a melting film that smoothes itself due to the surface tension and solidifies on cooling. The surface properties can also be controlled via the process control.

“With USP laser polishing, for example, it is possible to smooth out micro-unevenness while retaining macroscopic structures,” explains Saßmannshausen. The laser process also makes it possible to polish complex 3D surfaces with micrometer precision. Selective polishing of selected areas is also possible in order to adjust the surface properties locally or to polish only the necessary areas, which in turn saves time. USP polishing thus complements laser macro- and micropolishing with an even more precise and locally applicable approach to surface polishing.

© Fraunhofer ILT

Efficient process for industrial hard material processing

Depending on the process requirements, laser polishing achieves surface rates of ten to 100 cm² per minute, almost keeping pace with the surface rates of upstream material removal. “The combination of both processes with one laser in the same clamping enables companies to expand their range with existing USP lasers or to significantly accelerate amortization after a new acquisition,” explains Saßmannshausen.

Above all, however, it is suitable for replacing mechanical processes in the machining of hard materials and thus putting an end to the sometimes immense tool wear in their production. This not only reduces costs, but also contributes to greater resource and energy efficiency.

According to Saßmannshausen and Vogel, the potential of the process combination is far from exhausted. With faster polygon scanners, higher laser power and larger laser spots, it is possible to significantly increase the area rates.

Interested industrial partners are invited to tackle the optimization steps together with the Fraunhofer ILT research team.