Following the success of Amada’s ATC machines, of which more than 1,000 have been installed worldwide, the Japanese manufacturer has extended the company’s ATC technology to its mid-range series for the first time.

Amada’s HRB-ATC has a full-size automatic tool changer that offers the same number of tool positions as the high-end HG-ATC solution. This results in many advantages for companies that want to maximize the productive time of their press brake. The ATC can reduce setup times by 80 percent in many cases compared to a manual setup process by an operator, which is a clear advantage for subcontractors or companies that need to make multiple mold layout changes every day. The use of the offline software “VPSS 3i Bend”, which is supplied with the machine, brings further productivity benefits by eliminating manual programming by the machine operator.

Additional advantages for the user result from the rotation option (all punches can be installed positively or negatively) and the automatic crowning (compensation of deflections in the upper and lower press beam) which by default lead to an increase in productivity and precision respectively.

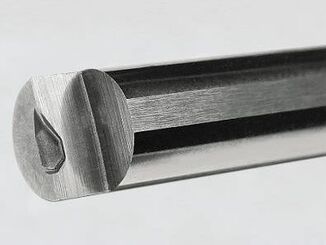

Experienced users of the HRB-ATC have commented positively on the flexibility and simplicity of the machine. The HRB-ATC is fully compatible with Amada AFH/Promecam standard tools, allowing for manual tool setup if required. The large AMNC 3i touchscreen 3D control with the new “Lite” mode offers further enhancements to speed up the operation of the control and simplify the introduction of new employees.

About AMADA GmbH

The Amada Group is one of the world’s leading manufacturers of sheet metal working machines. Amada GmbH offers a comprehensive range of cutting, bending, welding, punching and laser technologies. Modular automation components, software applications and a wide range of tools complete this offer. The Amada Group was founded by Isamu Amada in Japan in 1946. The German subsidiary Amada GmbH has been in existence since 1972.

Web:

www.amada.de