In order to counteract the health hazards posed by particulate matter, the EU is also setting specific limits for brake dust for the first time in the Euro 7 vehicle emission standard. Hard coatings applied by diode laser enable reliable compliance with all specifications and reduce brake dust with particle sizes below PM10 by up to 90 percent.

© Laserline

One of the greatest health hazards in urban areas is considered to be particulate matter emissions from road traffic. They are suspected of causing allergies as well as respiratory, cancer and cardiovascular diseases. By no means are the particles emitted solely as a result of combustion engines, but around a quarter of them are also due to abrasion from brakes. In the draft Euro 7 vehicle emission standard, which is due to come into force in 2025, the EU Commission takes account of this fact and for the first time sets specific limits for particulate emissions from braking systems. They also apply without exception to electric vehicles, which are thus affected for the first time by the EU regulations on pollutant emissions from motor vehicles. Automotive manufacturers are thus faced with the challenge of significantly reducing particulate emissions from braking systems.

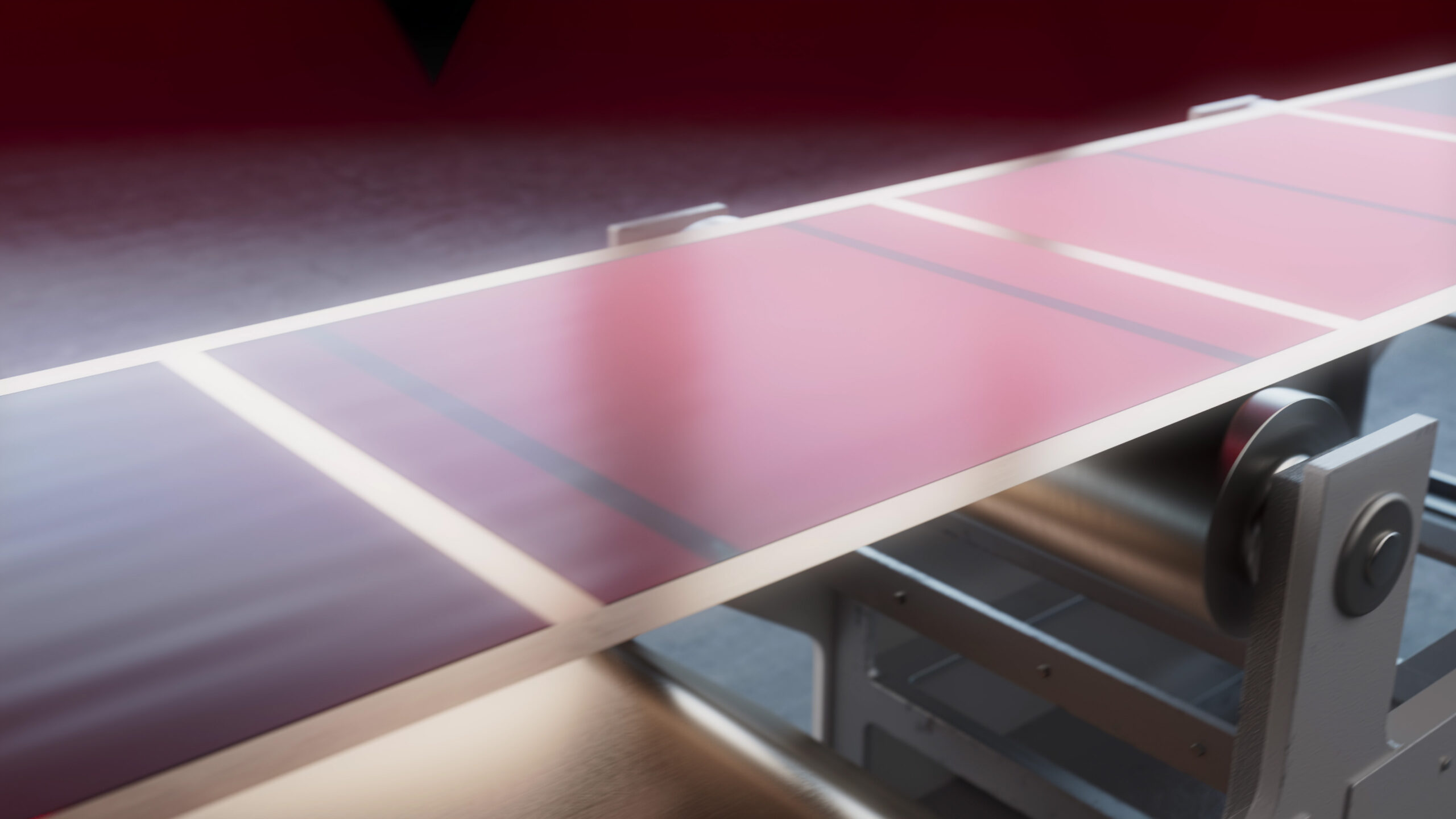

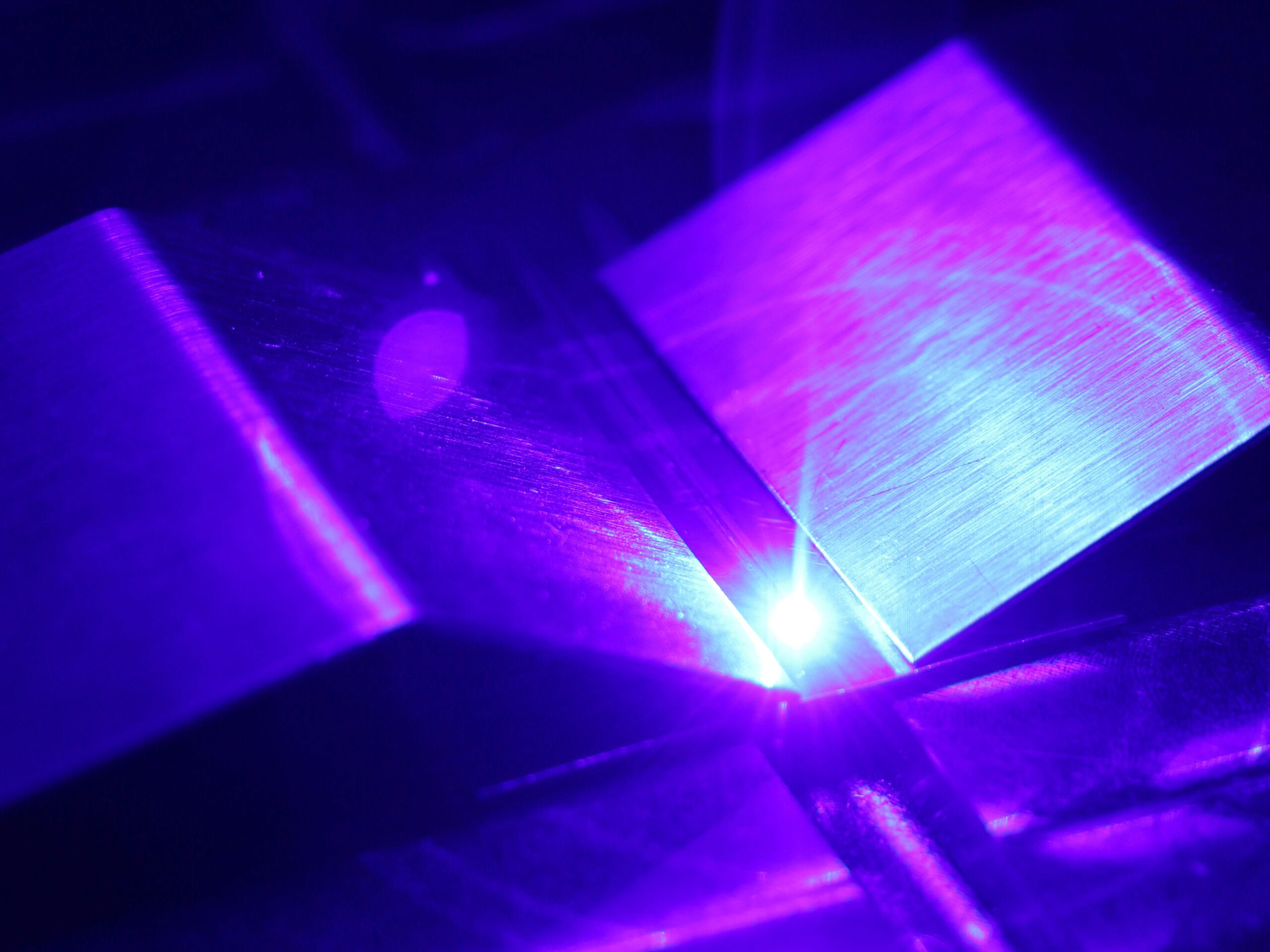

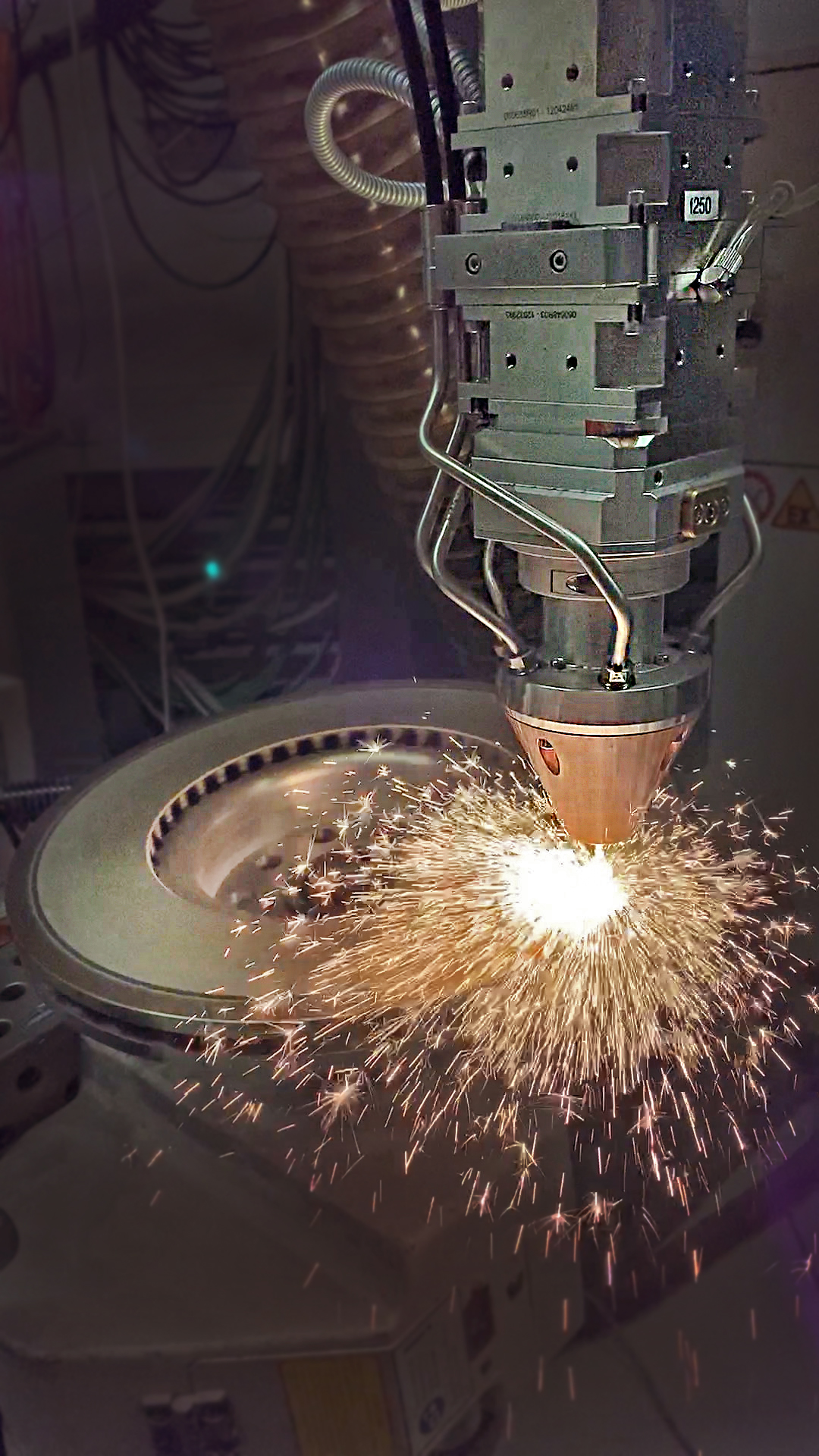

One of the most effective measures to reduce brake dust emissions is to coat automotive brake discs with hard coatings using diode lasers, which provide long-term abrasion and corrosion protection. The braking process-induced amount of health-endangering particulate matter with a maximum particle size of 10 micrometers (PM10) can thus be reduced by up to 90 percent. The Euro 7 emission standards, which are expected to be seven milligrams of particulate matter per kilometer, can thus be safely met. For the realization of such coatings, the commercially available gray cast iron material of the brake discs does not need to be adapted, nor do the classic production processes. The coating application takes place after completion of the actual brake disc and is only a supplementary production step.

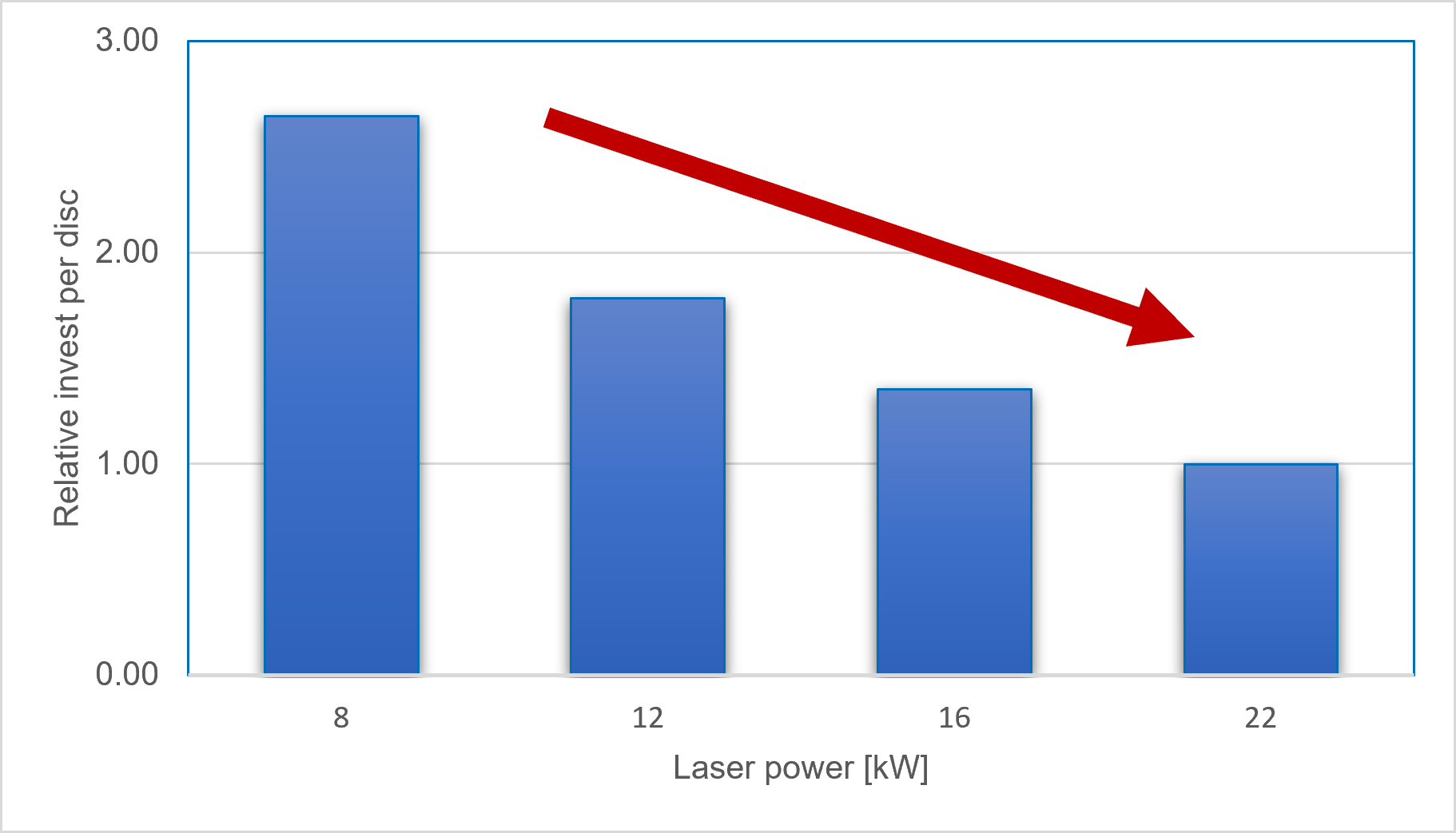

Diode laser specialist Laserline has developed the process setup of this method to series maturity together with its technology partners and, last but not least, ensured its integration capability in Industry 4.0 production environments. Using diode lasers with OPC UA interfaces and output powers of up to 22 kW, powder-based high-speed coating processes are implemented, with a process time of less than one minute per brake disc in some cases. This enables mass production, making brake disc coating affordable for all automotive market segments. By using the coating materials flexibly, it is possible, for example, to achieve very effective and at the same time cost-effective coatings even for vehicles in the medium and lower segments. In addition, the system configuration also influences the price. Thus, as laser power increases, throughput increases, which reduces the number of coating machines required, saves production space, and ultimately significantly reduces the relative investment per sheet.

© Laserline

More detailed technical information on Euro 7-compliant diode laser-based brake disc coating is available on the Internet on the Laserlin pages. Among other things, a white paper is available for download there that provides detailed information on the coating process and the materials used in this process. In addition, interested parties will also find process and explanatory videos as well as numerous additional information on Laserline diode laser technology.

Facts & Figures

Laserline GmbH, based in Mülheim-Kärlich near Koblenz, was founded in 1997. As a leading international manufacturer of diode lasers for industrial material processing, the company has become the epitome of this innovative technology and can look back on more than 25 years of history. Nearly 6,000 high-power diode lasers from Laserline are currently in use worldwide, demonstrating their performance in a wide variety of processes and applications. Laserline currently employs around 350 people and has international offices in the USA, Mexico, Brazil, Japan, China, South Korea and India, as well as representatives in Europe (France, Great Britain, Italy) and in the Asia-Pacific region (Australia, Taiwan). The company is focused on sustainable growth. The construction of an extensive building complex on the site in Mülheim-Kärlich has already created the spatial prerequisites for the future expansion of development and production.

Web:

https://www.laserline.com/de-int/die-bremse-fuer-weniger-feinstaub/