Laserline has succeeded in further increasing the output power of its series of blue diode lasers: at this year’s Laser World of Photonics, the company is presenting a 4-kW blue laser for the first time. Lasers of this wavelength enable more effective and energy-efficient processing of copper components in e-mobility manufacturing, among other applications. Laserline will also provide information on diode laser-based coating applications for brake discs and wind turbine components, as well as an innovative laser drying process for the series production of lithium-ion batteries.

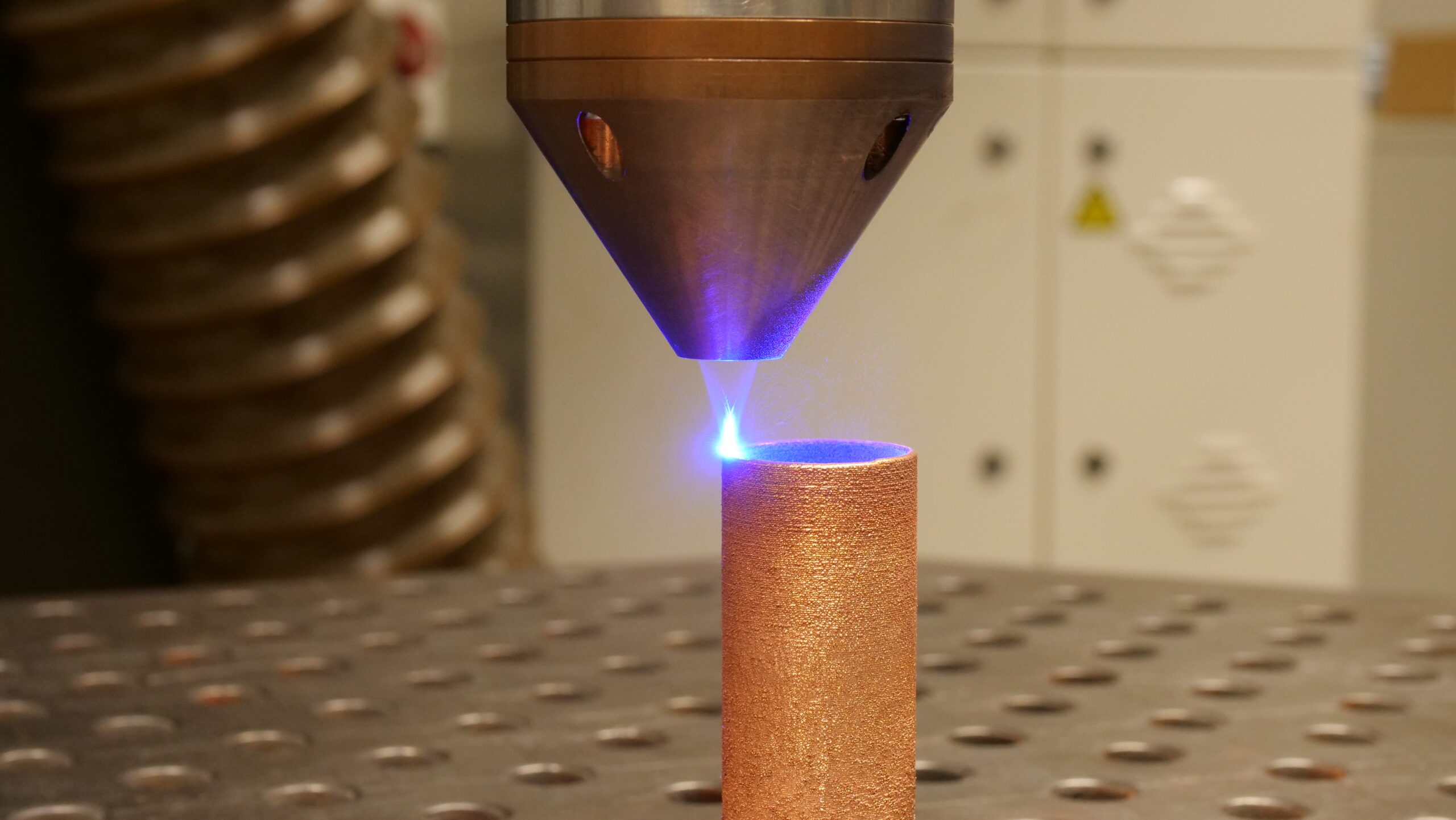

Copper welding in the electronics field, coating brake discs and wind turbine components, and drying for battery production – these application areas will be the focus of Laserline’s trade show appearance at Laser World of Photonics 2023 (June 27 to 30 in Munich, Hall B3, Booth 305). Highlights include the unveiling of the first blue diode laser with 4 kW CW output power. It was designed primarily for the machining and additive manufacturing of copper components and, according to Laserline, currently represents the highest performance class of industrial lasers in the blue wavelength spectrum. Like all blue Laserline diode lasers, the 4-kW laser operates at a wavelength of 445 nm, which is absorbed by copper alloys five times better than infrared radiation and thus forms an almost perfect melt pool without pores.

The increase in performance enables even more energy-efficient and faster processes in both welding and additive manufacturing. In addition, the new performance class is accompanied by manufacturing optimizations that will make it possible to increase the production numbers of the laser systems and permanently reduce market prices, making the use of blue lasers even more attractive in the future. In addition to the 4 kW system, a new 200 W pulsed blue diode laser for semiconductor applications, which will be on display as a prototype at the booth, shows that the range of applications is also continuously expanding.

© Laserline

Future-oriented coating applications with upgradeable infrared lasers

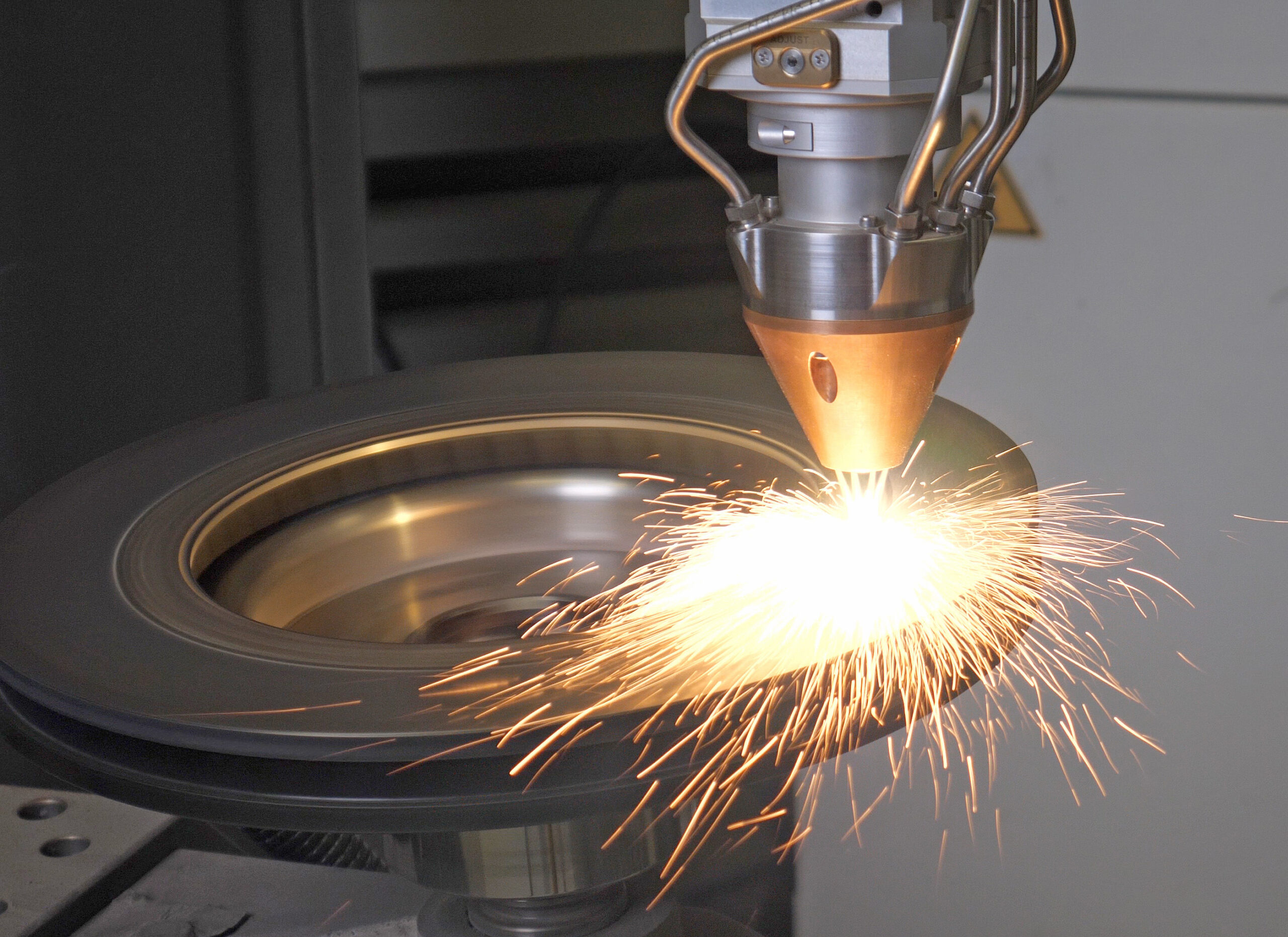

The second focus topic of Laserline’s trade show appearance is laser-based coating solutions, especially for rotationally symmetrical components such as brake discs for road and rail vehicles or plain bearing bolts for planetary gearboxes of wind turbines (WKA). Both technologies make a significant contribution to environmental and climate protection: Diode laser-based anti-corrosion and anti-wear coatings reduce the harmful particulate matter caused by brake discs and brake pads by up to 90 percent.

In the case of wind turbine bearings, diode lasers enable coatings that are gentle on resources and workpieces and have a long service life, which reduces the consumption of raw materials and significantly increases the service life of the plants that are elementary for the energy turnaround. The Laserline LDF series infrared lasers used in both application areas and exhibited at the booth are characterized by their flexible scalability and can also be upgraded in the field at any time. Once the process has been successfully established, it is then possible, for example, to upgrade the power from 12 to 24 kW without any problems, thereby roughly doubling the speed of the coating process.

Another product innovation that will be exhibited for the first time at Laser World of Photonics is a 10-kW diode laser from the LDM series in 19″ format. Integrators in particular can implement this design very easily and advantageously in existing machine concepts for welding and coating applications. With the new 19″ laser, Laserline has also succeeded in achieving a previously unattained packing density of 9.6 dm3/kW. This means that less than 10 liters of installation space are required for 1 kW of laser power – and thus only one-third of the space taken up by comparable fiber lasers.

Laser Drying for the Production of Lithium-Ion Batteries

Finally, the Laserline trade show presentation is rounded off by the presentation of a diode laser-based drying process that supports the low-emission and economical series production of lithium-ion batteries. It was developed under the leadership of Laserline as part of the IDEEL project (Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Production) and makes it possible for the first time to produce laser-dried anodes and cathodes in a roll-to-roll process. The diode laser with its homogeneous and precise beam shaping supplements or replaces convective drying, which has dominated the market to date, and reduces the total energy requirement of the drying process by more than 25 percent. Compared with conventional GigaFab drying lines with connected loads of over 1,000 kW, the new process ultimately enables a significant reduction in process-related CO2 emissions.