AutoForm Engineering, a leading supplier of software solutions for sheet metal forming and body-in-white processes, introduces its advanced software solution for tube parts. In addition to the new features in AutoForm TubeXpert, users can now further improve their tube bending processes by using the newly developed AutoForm-TubeBend software product.

© Autoform

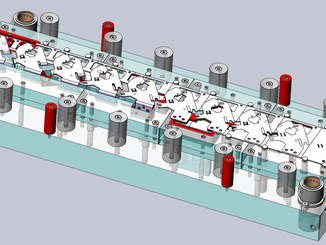

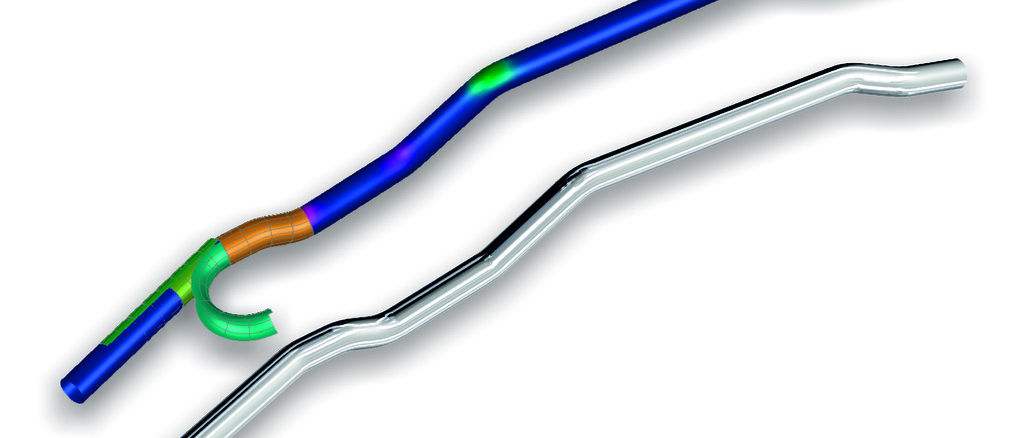

The enhancements in the latest version of AutoForm TubeXpert benefit users especially in tube bending, forming and hydroforming. This version features a completely new solver that offers new material laws, improved tube-tool contact modeling, and an improved meshing algorithm. With AutoForm TubeXpert, users can achieve more accuracy.

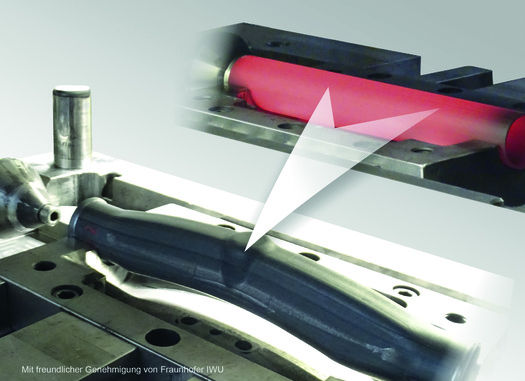

The software now supports hot forming processes of tubes including internal pressure forming (Hot Metal Gas Forming). This fairly new technology, which is now also included in the software, enables support for both direct and indirect hot tube forming processes. The expanded material library includes aluminum, stainless steels, manganese-boron steels, and titanium alloys suitable for hot stamping processes. In addition, the software supports advanced friction modeling with TriboForm.

In addition, AutoForm TubeXpert enables flexible process design, which is essential for expansion joints, bellows and tube end forming. With AutoForm TubeXpert, users can quickly set all relevant parameters required for such process design.

AutoForm-TubeBend is specifically designed to meet the needs of tube benders and supports their standard processes such as CNC mandrel bending, die bending and tube end forming. The software enables the rapid design and simulation of these processes. It also allows the user to simulate the springback that can occur in the actual production process. Automatic springback compensation allows the necessary adjustments to be made to the die geometry, bending line and process parameters. With this software, users can perform comprehensive virtual tryout analysis to efficiently reduce the number of tryout loops. With AutoForm-TubeBend, users can successfully master all typical challenges in tube bending and forming.

Dr. Markus Thomma, CMO of AutoForm Group, explains: “With our enhanced AutoForm Tube software solution, users are well equipped to meet the increasing demands on the complexity of tube components, the ever higher quality requirements for parts, the introduction of new materials, and the increasing process complexity. By using AutoForm Tube, our users gain a comprehensive and in-depth understanding of tube bending, forming and hydroforming processes. AutoForm Tube is our software solution for successful tube part design and simulation. The new version will be available in April.”

AutoForm Engineering GmbH provides software solutions for sheet metal forming and body-in-white processes. More than 400 highly qualified employees in this field work at AutoForm. The company is considered a leading provider of software for product manufacturability assurance, tool and material cost calculation, tool design and virtual sheet metal forming, and body-in-white process optimization. All of the top 20 automotive manufacturers and most of their suppliers use AutoForm’s software. The company is headquartered in Switzerland. Subsidiaries in Germany, the Netherlands, France, Spain, Italy, the Czech Republic, Sweden, the USA, Mexico, Brazil, India, China, Japan and Korea underline AutoForm’s international presence. In 13 other countries, local sales partners ensure proximity to customers.

Web:

www.autoform.com