AutoForm Engineering, a leading provider of software solutions for sheet metal forming and body-in-white processes, introduces its latest software release AutoForm Forming R13. This version offers new capabilities and enhancements for the sheet metal forming process chain, most of which have been developed for the feasibility and validation phase. In addition, AutoForm Forming R13 features reduced file sizes, allowing significantly smaller simulation files without compromising results or affecting engineering decisions.

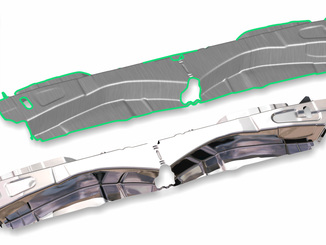

AutoForm Forming R13 offers enhancements and new options for the feasibility phase of the forming process. This version introduces new result variables that enable accurate wrinkle detection and give users a deeper insight into the occurrence and development of wrinkles during all forming operations and springback.

Users can also easily track the development of wrinkles and visualize and evaluate wrinkle behavior throughout the forming process. The new result variables enable an optimized and more reliable evaluation of wrinkle behavior.

Surface roughening is now integrated into TriboForm’s contact and friction models, which is particularly important for aluminum parts where surface changes have a significant impact on formability.

AutoForm Forming R13 also offers significant improvements in terms of data continuity and ease of use during method planning. The software enables users to automatically transfer conceptual tool geometries from AutoForm-DieDesigner to AutoForm-DieDesignerPlus, where they can be further processed into high-quality CAD surfaces for manufacturing.

The seamless data flow combined with the process plan information from the earlier concept development phase enables users to achieve a new level of efficiency in method planning.

Dr. Markus Thomma, CMO of the AutoForm Group, explains: “With AutoForm Forming R13, we are offering our users new enhancements and options that are important for the sheet metal forming process chain. These new options have been developed to increase the reliability of the simulation and enable more precise technical decisions.”

Friendly takeover

AutoForm Group has acquired Stampack GmbH, strengthening its position as a leading global provider of sheet metal forming technologies. Stampack’s expertise and software portfolio, particularly in the areas of explicit solver technology and solid element simulations, complement AutoForm’s comprehensive range of solutions and create new opportunities for innovation and customer value.

Stampack’s software is based on an explicit solver technology that efficiently processes cases with rapid deformations and complex contact changes. In addition, the software enables reliable validation of forming processes for parts with thick sheets, small radii or reduced material thickness.

By adding Stampack’s software to its software product suite, AutoForm will be able to better support its existing customers, including LogoPress customers, in addressing their sheet metal forming challenges while expanding its customer base in the automotive, aerospace, appliance and electrical industries. Stampack will benefit from AutoForm’s 20+ years of experience in sheet metal forming and its track record of global implementation. This symbiotic combination will provide greater value to existing customers while opening up new industries for further growth.

In addition, the acquired technology, explicit solver technology and solid element simulation, will be able to open up new application areas such as structural dynamics, ballistics and defense as well as complex assemblies in various industries such as shipbuilding, construction, energy and infrastructure.

Web:

www.autoform.com