Siebenwurst Werkzeugbau (SWZ) offers tools for all areas of stamping and forming technology. The company also offers all services individually, from engineering and mechanical processing to spotting work in the tryout process. The company’s main area of expertise lies in sophisticated body parts, chassis components and acoustic and thermal shielding for the automotive industry. By using AutoForm software at the Zwickau site, the company goes many a step further than other toolmakers.

© SWZ/AutoForm

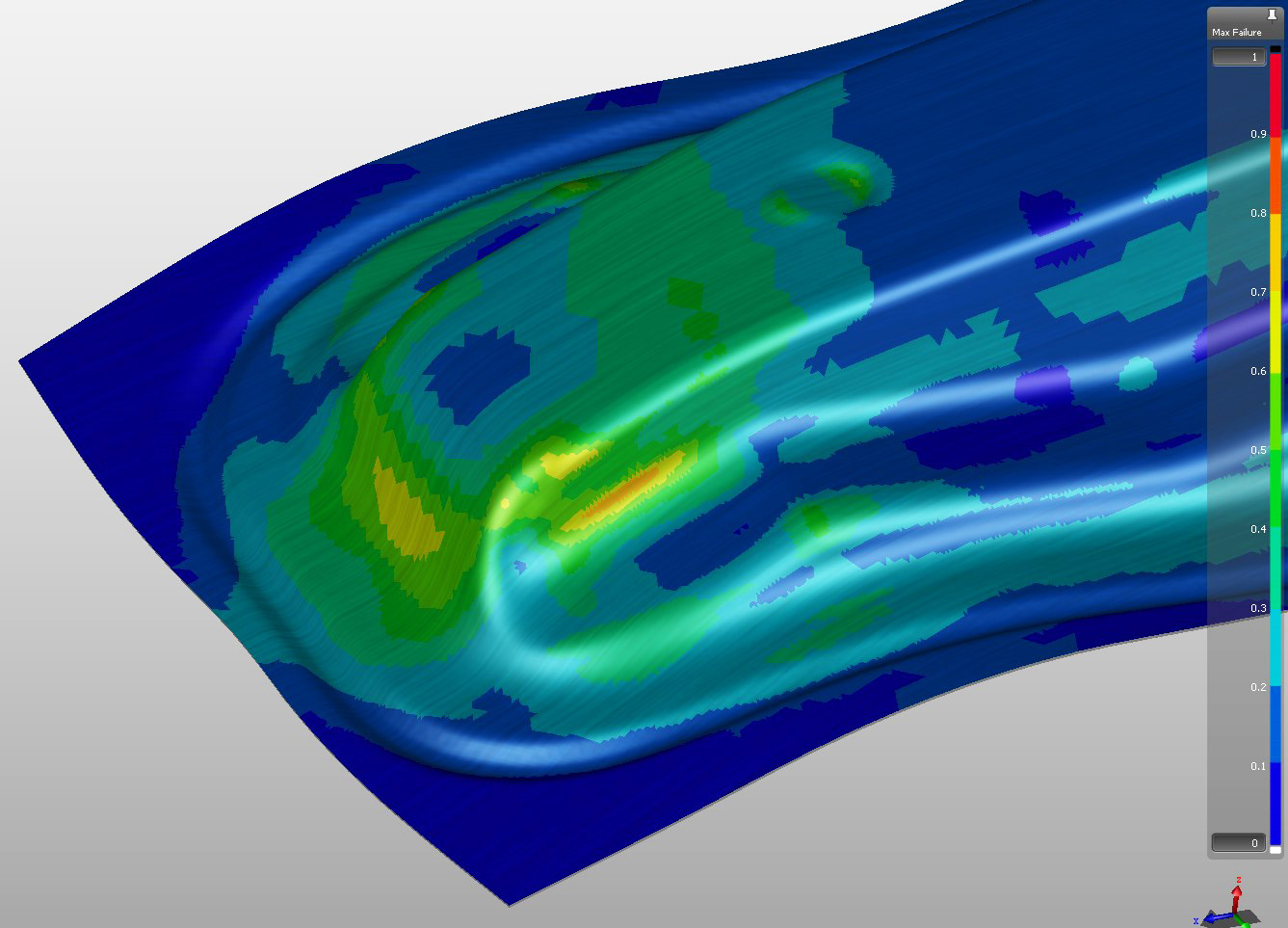

At Siebenwurst, too, work begins with simulation before the actual tool is manufactured, based on standards and experience. All subsequent development steps are based on the resulting tool surfaces. As soon as real data from the tryout is available, it becomes clear how well simulation and reality match. The original assumptions are then checked and compared with reality. For example, SWZ determines the real material characteristics of the tryout material and compares them with the originally assumed values from the simulation. In the specific case of a front flap, it became clear that a coherent picture only emerged through the integration of the actual material data, so that the simulation and the real behavior were close to each other. Siebenwurst follows a clear approach that includes the simulation process right from the quotation and engineering phase. But this does not end with the milling approval. This makes the simulation a dynamic companion in the process, which is continuously updated and acts as a digital twin for optimization during the entire production process.

Full service supplier for tools

With this methodology, the AutoForm software and the technologies used, Siebenwurst Werkzeugbau has continued to develop over the last few years and produces the most complex tools for a wide variety of sheet metal parts. The company, headquartered in Dietfurt, not only supplies its national and international customers with tools, but also supports them from the transfer of CAD data and the start of the feasibility study, through method planning and simulation, to tool production, tool testing, sampling and quality assurance.

© SWZ/AutoForm

“The classic simultaneous engineering approach, in other words, with which we make suggestions for the production-safe manufacture of components,” emphasizes Managing Director Christian Siebenwurst. “In addition, we also produce pre-series for our customers, manufacture prototype tools and offer a comprehensive service concept for the maintenance of tools during ongoing parts production.”

Christian Siebenwurst founded Siebenwurst Werkzeugbau GmbH in Zwickau on January 1, 1991, after having been in contact with the former repair tool shop of the Sachsenring press shop since the 1980s. A design department was set up relatively quickly and the construction of new tools began, with the result that new tool construction now accounts for 50 percent of turnover.

“We traditionally come from transfer tool manufacturing, but in the last 10 or 15 years we have been producing more and more large stepped tools. So while we were originally active in the field of structural components, we are now also active in outer skin parts,” says Christian Siebenwurst. “Because toolmaking has almost completely migrated to Asia in the last 10 or 15 years, we are not only under considerable economic pressure, we also need high-performance technologies in order to meet the high demands of OEMs, system suppliers and pressing plants. Simulation with AutoForm is a very important part of this.”

© SWZ/AutoForm

Incremental to high prediction accuracy

AutoForm’s software solutions are now firmly woven into SWZ’s value chain. “It starts with the customer inquiry, where we generate the first parametric tool surfaces with the AutoForm DieDesigner,” explains David Weber, Head of Engineering. “By using process simulations right from the start, we want to be as close as possible to the result in the quotation phase and thus achieve a high level of cost prediction accuracy.” The one-step simulation used in previous years is now the exception, as the focus is on validation and forecasting accuracy.

The path to the green component

Design work in Zwickau is primarily carried out using Catia V5, which acts as an interface to AutoForm-DieDesigner. “This allows us to examine manufacturability in great detail. Even before the order is placed,” emphasizes David Weber. “If something doesn’t work, the necessary component changes are recorded for the tender submission. For us, the aim at this point is to arrive at a suitable offer with as much certainty as possible. Once the order has been placed, we then determine in detail how the part is to be manufactured.”

© SWZ/AutoForm

The various OPs are developed in AutoForm-DieDesigner. If required by the customer, SWZ also uses the TriboForm plugin for incremental simulation. “Based on local variables such as the surface roughness of the sheet metal and tool, oiling pattern and lubricant quantity, changing friction conditions are incorporated into the simulation,” summarizes Leonard Krauss, Global Key Account Manager at AutoForm. “This is a decisive factor, especially with aluminum.”

Game changer: digital inking

The fact that Siebenwurst is always open to new approaches is demonstrated by digital spotting, for which a pilot project was driven forward together with AutoForm in 2024. In this case, it involved a double tool for BMW AG. “When you have such a tool in the press for the first time with the conventional procedure and you drive onto the part for the first time, challenges regularly arise. Cracks or waviness can occur on the component and then we have to create the drawing flow manually,” says David Weber, describing the procedure. There is a risk of moving further and further away from theory. The amount of manual work increases and at some point the theory can be discarded under certain circumstances. “That’s also the reason why we opted for digital inking: It allows us to reduce a lot of the manual work that is of course still necessary,” reports David Weber. This was also the case with the double tool: there were no cracks or creases after it was brought together. This shows “the huge potential of digital spotting.”

As part of the incremental simulation, other input parameters are used here so that the contact between the sheet metal and the tool can be mapped exactly. “In the simulation, the thickenings and thinnings are first determined and adjusted so that, for example, the thickened sheet metal fits exactly in between,” explains Leonard Krauss. “Depending on the component, this can save the tryout team days of work.”

© SWZ/AutoForm

Something is moving

Siebenwurst and AutoForm have been working together for more than two decades. In recent years, the collaboration has become even more intensive. A culture of discussion has been established, and customized training has been provided on the simulation accuracy of SWZ components. “The AutoForm-DieDesignerPlus could also become interesting for our work in the future,” says Christian Siebenwurst, looking ahead to the next steps. The advantage of the Plus version is that it also functions as a design tool, which is why CAD surfaces can be created directly in AutoForm. “This would allow us to save on CAD licenses,” adds the Managing Director. However, increasing customer acceptance of such tools is a process. The first OEMs are now accepting the AutoForm DieDesignerPlus parameters. The same applies to digital spotting. So something is moving in the automotive industry. In favor of covering two worlds.

Background

AutoForm Engineering GmbH provides software solutions for sheet metal forming and body-in-white processes. More than 400 employees work in this specialist area at AutoForm. The company is a leading provider of software for ensuring product manufacturability, calculating tool and material costs, tool design and virtual sheet metal forming as well as optimizing body-in-white processes. All of the top 20 automotive manufacturers and most of their suppliers use AutoForm’s software. The company is headquartered in Switzerland. Subsidiaries in Germany, the Netherlands, France, Spain, Italy, the Czech Republic, Sweden, the USA, Mexico, Brazil, India, China, Japan and Korea underline AutoForm’s international presence. In more than 10 other countries, local sales partners ensure proximity to customers.

Hall 8, Stand 8217