“At the international marketplace for sheet metal working, we will be showcasing the latest technology standards for customer-specific solutions with the highest quality,” claims Simon Telöken, Teka Managing Director, for his company.

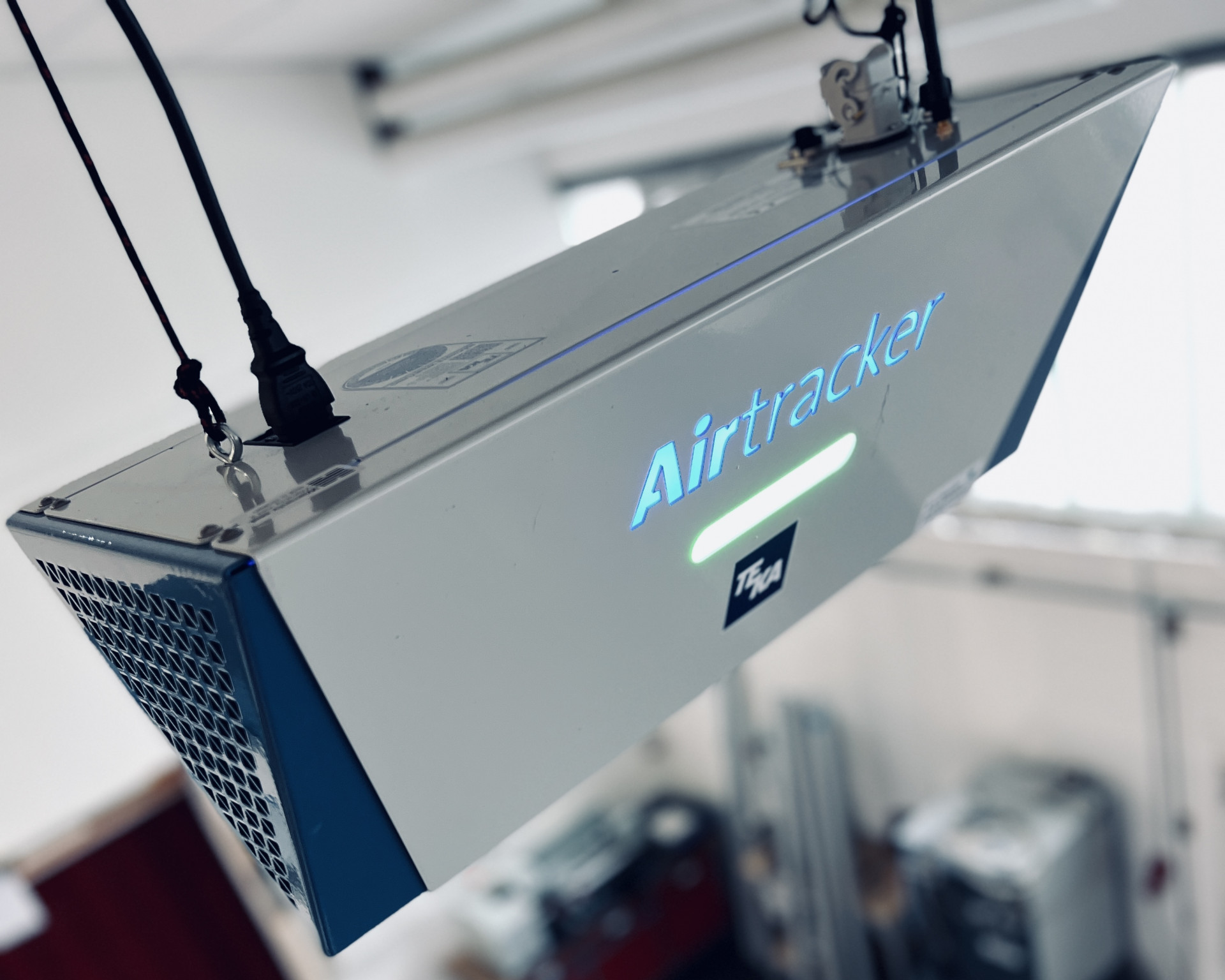

© Teka

“We are one of Europe’s leading manufacturers of extraction and filtration systems. Particularly for the entire technology chain of sheet metal processing, we can draw from the wealth of our modular system and design an individual special solution for each customer according to the situation. This is precisely our message to the industry’s leading trade fair,” says Simon Telöken, Teka Managing Director. The Teka team is looking forward to helping shape Euroblech in Hanover from October 25 to 28, 2022.

At the 143 sqm booth in Hall 13 at Stand F58, international trade visitors will be able to gain an insight into the entire product range of Teka equipment. Versatile application possibilities can be demonstrated in discussions with the qualified field service. “We score points in the market as an all-rounder for innovative special solutions with high service and quality standards. Our versatile configurable systems give us the scope to do this,” continues Telöken, referring among other things to systems such as the FilterCube, which can be individually configured as a modular system.

The internationally active manufacturer is staging its AirCube, ExCube and VarioCube as trade show highlights and is also demonstrating innovative strength in the megatrends of sustainability and digitalization.

More efficient, more sustainable and smarter – the AirCube

The AirCube is the latest Teka development to take digitized extraction and filtration technology to a new level, making it accessible to small and medium-sized businesses. The mission of this plant: Filtering 4.0. Behind Smart Filtering is an increase in performance. The intelligent system stands for resource-saving work and at the same time offers more efficiency in extraction and filtration. Its intelligent technology thus enables greater process reliability for high-quality products. With VarioControl at its heart, the system offers added value through networking, as it is able to conduct machine-to-machine communication via MQTT or with OPC UA interfaces.

The AirCube is Teka’s most digitized system, while also meeting IBN 4.0’s Ready-To-Go standards. It extends the standing times, and can decide independently, for example, whether the air should be fed back into the hall or exhausted into the open air. It saves compressed air and energy through efficient cleaning, reducing energy costs andCO2 emissions. With power ratings between 5.5 kW, 7.5 kW and 11 kW, the Teka innovation is predestined for various areas of application. Six different upgrade packages allow users to tailor the AirCube configuration and make it even smarter according to their needs.

Explosion protection with system – the ExCube

With the ExCube series, Teka offers a plant innovation for greater safety when handling explosive materials. Thus, as a highly efficient filter system, the ExCube is especially suitable for safely and effectively separating explosive media in the manufacturing process. The product innovation was developed to extract and filter fumes and dusts generated during laser, plasma and oxyfuel cutting processes, as well as many other processes. All explosive dusts of explosion protection class ST 1 can be safely separated. Above all, the compact footprint of the basic model at 800 mm x 800 mm is a key system advantage for many fields of application.

Welding large components – with the VarioCube

For bulk welding at shipyards, in steel tank construction and also on construction sites with steel construction, Teke recommends its VarioCube for clean air. It combines compact dimensions and a robust design with maximum flexibility and user-friendliness. The VarioCube was specially designed for large welding shops. The housing (800 mm wide x 1200 mm deep x 2900 mm high) is made of 5 mm thick sheet steel and requires no more floor space than a Euro pallet. No component projects beyond the footprint dimension.

The unit has six stable suction flaps for connecting suction hoses. The extraction hoses connected to this can take in the polluted air via distributors at up to 12 workplaces at the same time. They record the emissions precisely at the point of origin. With the aid of a high-performance turbine, the system generates a pressure of up to 10,000 pascals and can capture air containing pollutants with nominal hose diameters of between 100 mm and 50 mm. The filter cartridges separate even fine dusts at a rate of more than 99.9 percent. An integrated pre-separator increases filter service life and minimizes the risk of fire.

“Our plant highlights are proven specialists in their field. In order to make the full range of possible applications of our products even more present in the market, we are focusing above all on the ‘human interface’, because the need for advice and also the project requirements are increasing. We are also taking this development into account with our field service, which has been strengthened again this year,” says Simon Telöken about the service philosophy, which can also be experienced at the Teka trade fair stand at Euroblech 2022. Trade fair visitors can also look forward to new digitization standards, which will be presented at the IndustryFusion Fondation 13 E 112 booth.

Web:

www.teka.eu