“Careful, it gets dirty here!” warns Joris Bijkerk before he pushes aside the red slatted curtain and enters his “dream come true.” Here, in the “Welding and Cutting” room, amateur craftsmen can work on metal parts to their heart’s content. But that’s not all the open workshop in Bocholt, Münsterland, has to offer do-it-yourselfers and DIY artists.

© Teka

When using the machines, the safety and health of workshop visitors play a major role.

On 530 m² and two floors, the 47-year-old from Bocholt has fulfilled his dream of a Makerspace and set up workshop areas for electronics, woodworking and metalworking, among others, which can be used by members. There are already more than 300 such places throughout Germany where “makers” can pursue their passion. How he came up with the idea? “At some point, the home workshop was simply too small,” says the managing director of the non-profit company, which was founded last fall, with a twinkle in his eye. “In fact, I want to offer people of all ages the opportunity to work and build together,” says Joris Bijkerk’s goal. “Just do it” is therefore the motto for hobby craftsmen and all those who want to become one. For a small fee, the engineer also offers startups not only space and tools, but also expert knowledge and the opportunity to network with one another.

“Safety is paramount”

“The safety of workshop users is the top priority. Before getting to work on the equipment and machines, everyone first receives detailed safety instruction. The necessary protective equipment is also provided,” Bijkerk emphasizes. Two “Filtoo” systems from Teka now ensure clean, healthy air in the cutting, welding and electronics areas. They remove smoke, dust and gas generated during welding, cutting and brazing directly at the point of origin, filter the polluted air and return it to the work area in a purified state. The W3-certified plant even absorbs health-endangering smoke and dust particles generated during the processing of stainless steel. “The units with four-stage filter system work reliably and can be used at any workplace thanks to the swiveling extraction arm and castors,” says Bijkerk with satisfaction.

© Teka

Icing on the cake in the safety concept

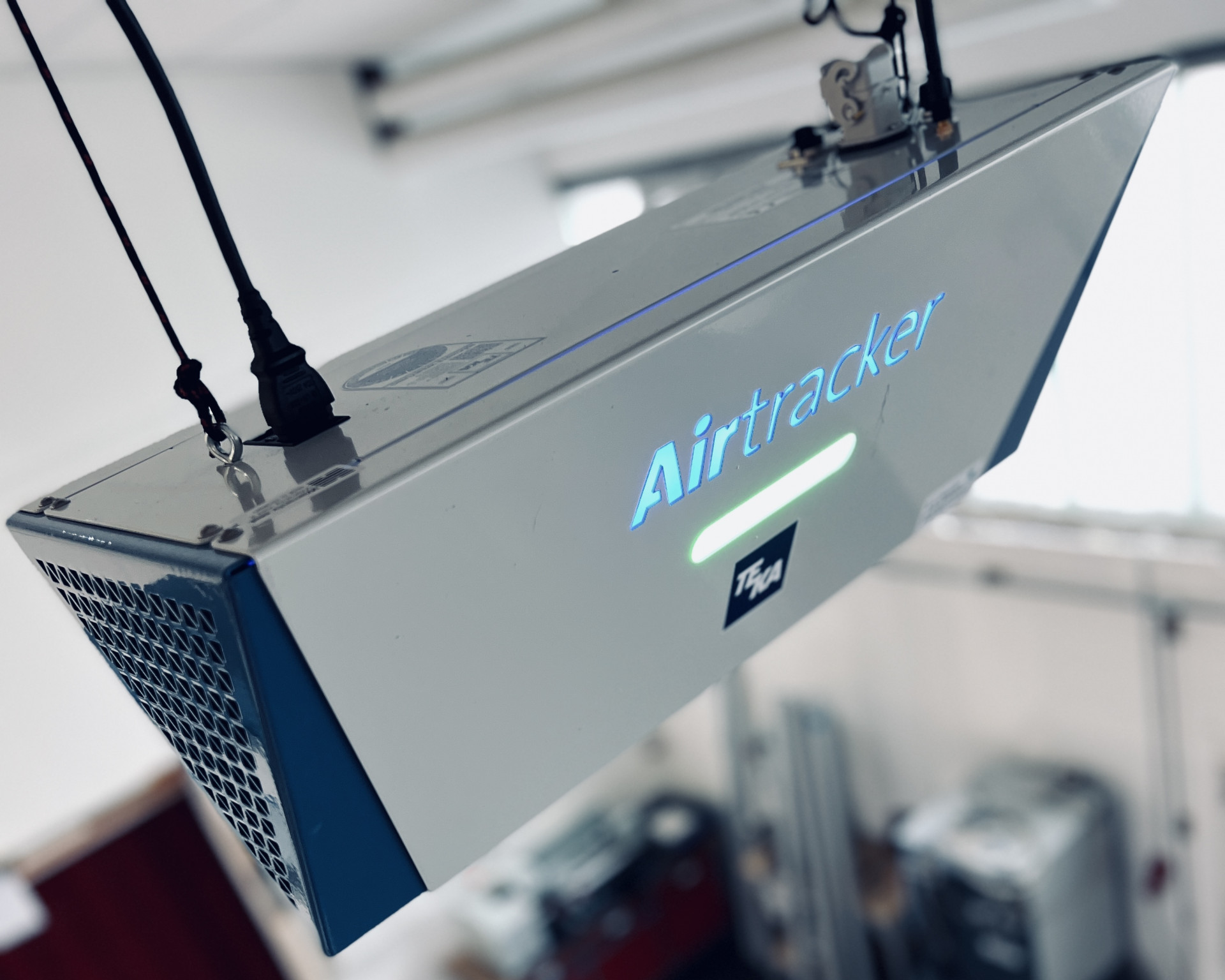

Up on the pedestal, the Bocholt native, who has been building things since he was a kid, has a small-format LMD connected directly to a laser system for cutting and engraving wood, cardboard and plastic, and sucking up all the particles created in the process. And just a few steps away, an Airtracker from Teka monitors the indoor air in the large hall. “The monitoring device is the icing on the cake in our air safety concept and shows us at any time how the air quality is in the Makerspace,” says Joris Bijkerk.

The company Teka, located in Coesfeld, has a lot of experience in the field of air technology. For more than 25 years, it has been manufacturing mobile and stationary extraction and filtration systems, with a particular focus on special machine construction. Teka CEO Simon Telöken is enthusiastic about the project: “I myself am a passionate hobby builder with my own small locksmith’s workshop at home. I think the idea of an open workshop where everyone can live out their craft and artistic potential is simply fantastic and I’m delighted that we were able to support the startup here.”

Web:

www.teka.eu/