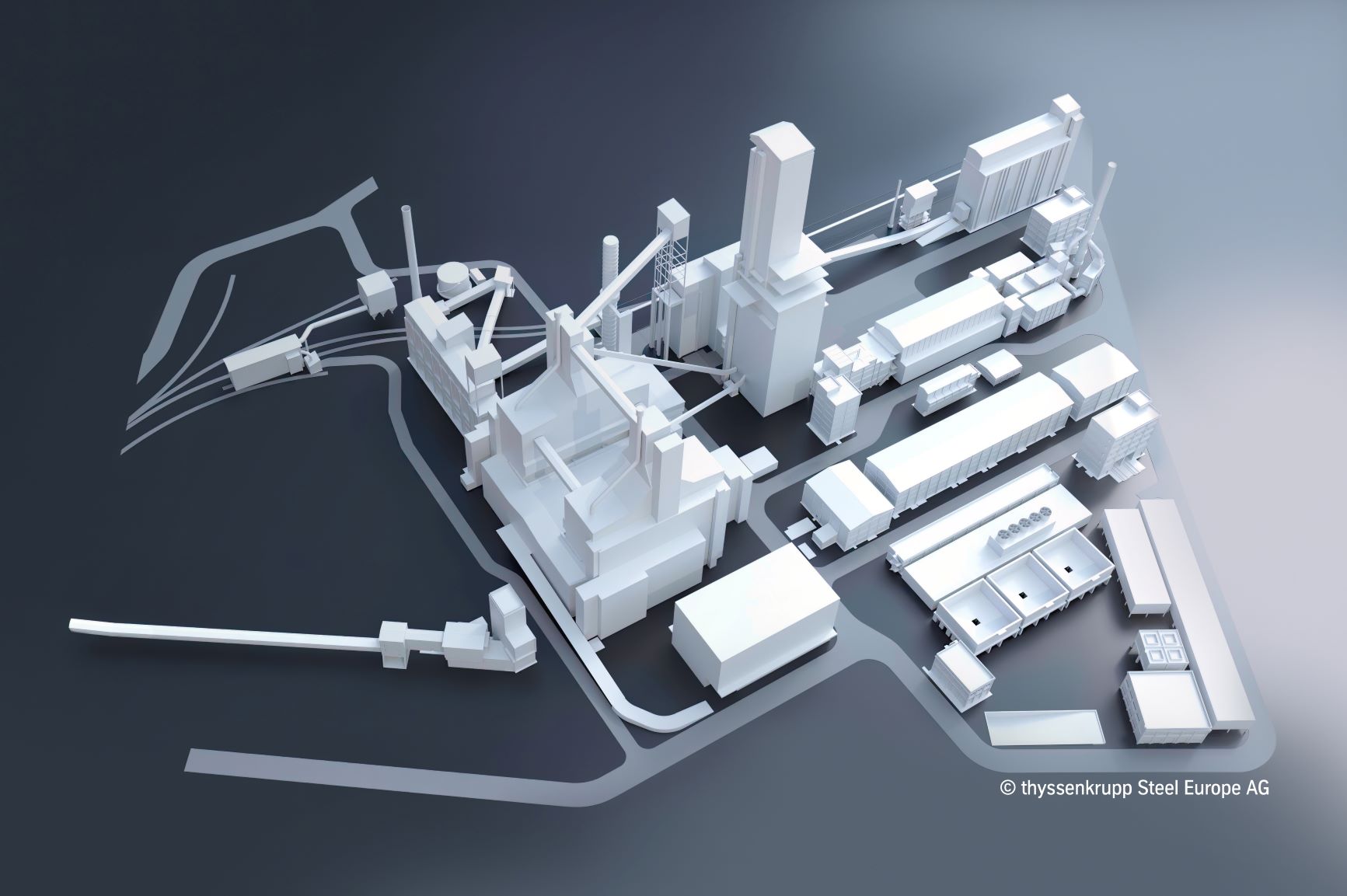

C.D. Wälzholz GmbH & Co. KG is setting the course for a climate-neutral future with the planned switch to CO2-reduced steel from thyssenkrupp Hohenlimburg.

Demand for CO2-reduced steel from thyssenkrupp continues to rise. C.D. Wälzholz GmbH & Co. KG from Hagen will in the future use high-precision hot-rolled strip made of climate-friendly steel from thyssenkrupp Hohenlimburg for the production of special materials. The Waelzholz Group and thyssenkrupp Hohenlimburg signed a memorandum of understanding in mid-October for the supply of climate-friendly Bluemint Steel from 2023.

© Thyssenkrupp

A complete range of goods becomes climate-friendly

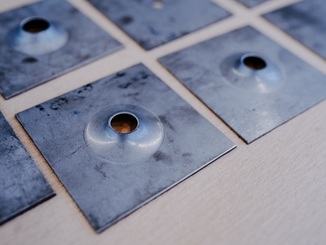

Waelzholz, a long-standing strategic partner of thyssenkrupp Hohenlimburg, uses high-precision hot strip for the production of cold-rolled special materials for high-quality applications in the automotive, energy and industrial sectors. By 2030 the quantities of CO2-reduced steel purchased from Waelzholz are to increase step by step. It will be supplied as unpickled and pickled medium-wide strip in the entire product range and up to a width of 720 mm by thyssenkrupp Hohenlimburg.

“We are pleased to be able to offer our long-standing customer Waelzholz high-precision hot-rolled strip for the production of special materials also in climate-friendly versions. Both partners will benefit from this, as our certified steels with reduced CO2 intensity will improve the carbon footprint of both companies,” promised André Matusczyk, Chairman of the Executive Board of thyssenkrupp Hohenlimburg GmbH. And Dr. Matthias Gierse, Managing Director Sales and Purchasing at C.D. Wälzholz GmbH & Co. KG, added: “The path to climate neutrality for steel products can only be taken together with all partners in the value chain. The agreement now reached with our long-standing supplier Thyssenkrupp Hohenlimburg on the long-term supply of CO2-reduced hot strip is an important step in this direction. Together we are pooling our strengths with this agreement to intensively expand our portfolio of climate-friendly products in the future.”

Designing a sustainable value chain

Both partners pursue the same goal: sustainable and climate-friendly production. With Bluemint Steel, thyssenkrupp Hohenlimburg already offers steel products with around 70 percent lower CO2 intensity.

Waelzholz has set up an ambitious Green Steel Roadmap with various projects to drastically reduce the CO2 emissions of its own products and production. Since the largest part of Waelzholz’s carbon footprint is caused by emissions from the pre-material chain, it is crucial for the company to reduce this CO2 content.