At Euroblech thyssenkrupp Steel (TKS) presented an extensive portfolio of hot-rolled and medium-wide strip materials: Perform HD displays particularly good processing properties for vehicle construction, Precidur combines high formability with sufficient strength for safety-relevant components. However, the “green” steel grade Bluemint also deserves special attention.

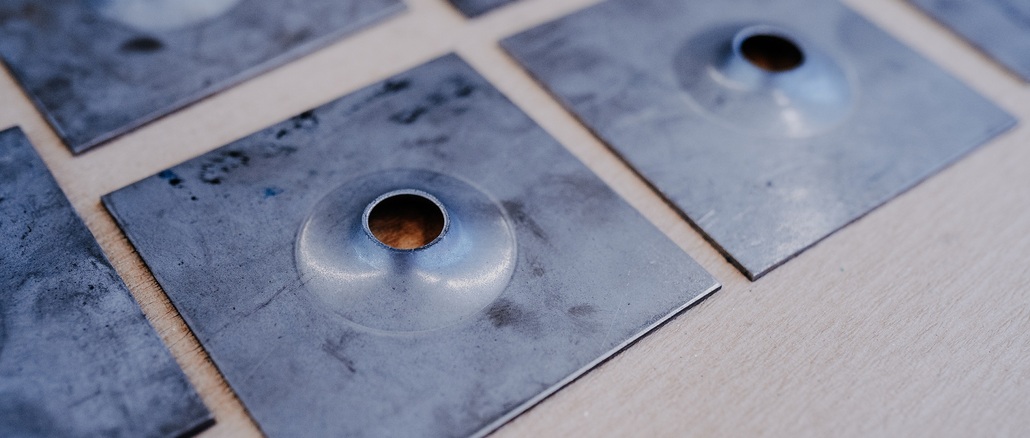

When significantly improved formability is required for complex component geometries in the area of axles or wheel suspension, highly ductile microalloyed fine-grained structural steels are the first choice. For this purpose thyssenkrupp Steel has developed Perform HD as hot-rolled wide strip and the particularly close-tolerance medium-wide strip Precidur HSM HD. The special microstructure of the highly ductile microalloyed grades ensures stable mechanical properties.

New to the range: microalloyed HD steels Perform in the yield strength range from 315 to 550 MPa (hot-rolled wide strip) and the two newly developed grades Precidur HSM 380 HD and Precidur HSM 420 HD (medium-wide strip). The CH-W 660Y760T chassis steel is now also available hot-dip galvanized. The latter is the lightweight solution for single-shell control arms and comparably demanding components.

For the optimum component-related material selection

Due to their good processing behavior, hot-rolled microalloyed steels have proven their worth in vehicle construction – especially in the areas of chassis and seats. The new high-ductility (HD) grades from thyssenkrupp Steel have a convincing property profile that is tailored to the application and uniform, while at the same time offering increased forming potential. “Compared to the standard, the new microalloyed HD steels are characterized by a much narrower range of mechanical properties and have a significantly increased elongation at break,” says product manager Arne Schreiber. “With the higher-strength grades, the component weight can additionally be reduced. Perform-HD steels are best suited for seat components such as underbody side panels and seat rails, or in the axle or wheel suspension area.”

That little extra for complex components

Precidur is used in almost all branches of industry. Particularly in the case of safety-relevant components, functional and design aspects are increasingly playing a role alongside reliability, which, according to TKS, require the highest forming capacity of the base material. Hot-rolled fine-grained structural steels such as Precidur HSM 380 HD and Precidur HSM 420 HD are particularly suitable for this purpose. They are characterized by symmetrical strip profiles and the natural rolled edge. Compared with the proven microalloyed fine-grained structural steels, they allow increased forming potential with the same strength.

The advantages of microalloyed Perform-HD steels at a glance:

– Improved cold formability for complex component geometries

– Guaranteed narrower range of mechanical parameters compared to VDA 239-100 and DIN EN 10149-2 standards

– Significantly increased elongation at break

– Lightweight potential through sheet thickness reduction

– Narrowest thickness tolerances for hot wide strip

– Excellent surface quality

– Reduction of production costs in the press shop thanks to application-specific property profile