The new “BrightLine Scan” technology improves robustness and stability in the welding process and enables particularly uniform weld seams. The process allows users to move the laser beam across the robot and optics simultaneously. This doubles the maximum plate thickness for heat conduction welding.

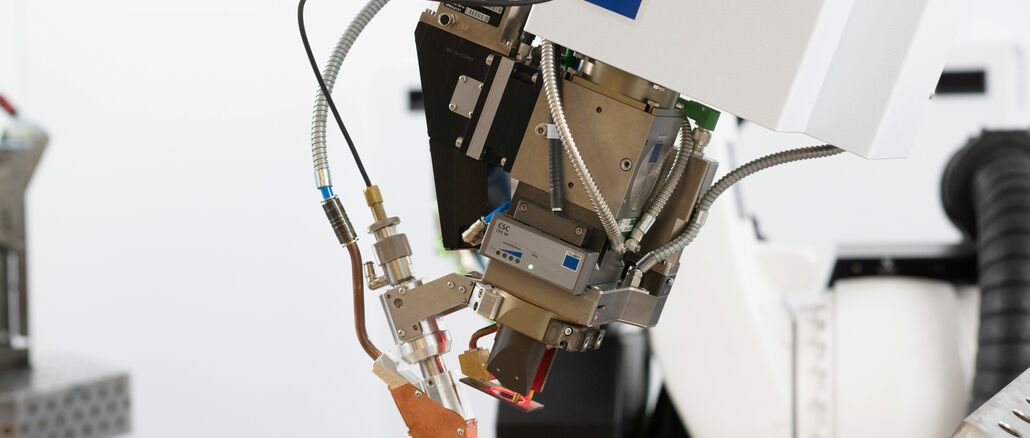

At Euroblech 2022, Trumpf will be launching BrightLine Scan, a new process for greater quality and robustness in laser welding. Until now, users could only control the laser beam during welding via the welding robot. With the new technology, the laser beam can also be moved over the laser scanner. In addition to the forward movement of the robot, this combination of robot and scanner also enables another freely programmable laser movement in any direction.

Specially developed lightweight mirrors make this so-called “oscillating motion” possible. As a result, frequencies in the kilohertz range can be achieved, and the possible sheet thickness doubles from three to six millimeters during heat conduction welding. With the new technology, users can individually adjust the bonding surface of the components, which is melted directly by the laser beam, depending on the application. This increases the process reliability and quality of the components.

With the additional beam guidance via the scanner, the tolerance of the process also increases. “With BrightLine Scan, Trumpf as a solution provider is once again demonstrating that we have the requirements of sheet metal manufacturing companies in mind. Companies have great advantages with the technology in their daily work, as they produce less scrap and save time and costs due to the higher tolerances during welding,” promises Trumpf Product Manager Martin Geiger. Trumpf will offer the technology for its TruLaser Weld 5000 laser welding machine starting at Euroblech.

© Trumpf

More robustness thanks to double beam guidance

With BrightLine Scan, the movement of the laser beam via the laser scanner is provided by the freely programmed PFO 20 focusing optics developed by Trumpf, which the Trumpf developers integrated into the welding optics of the robot. The combination in laser movement of robot and scanner significantly increases the robustness and flexibility in laser welding.

“For a high-quality welding result, we previously had to place the laser beam directly above the weld seam. Even with deviations of less than one millimeter, the component was often unusable. With the additional beam guidance via the scanner, the tolerance of the process increases. Small inaccuracies in preceding work steps can be compensated for, for example when bending,” explains Geiger.

Simple programming and application

Thanks to the seamless integration of BrightLine Scan into the robot’s welding optics, the Trumpf welding cell can be programmed quickly and easily as usual. Trumpf provides companies with the parameters for all common applications in so-called TechSets.

Companies can also use BrightLineScan in the TruTops Weld offline programming of the welding cell. This allows the machine to be programmed while it is welding parts. “Small and large quantities can thus be produced quickly and economically. In addition, we counteract the shortage of skilled workers because we can store basic information about the process directly on the machine,” Geiger concludes.

As sheet thicknesses of up to six millimeters can be welded with particular process reliability, the technology is particularly suitable for agricultural or construction machinery. Due to the high precision and quality of the weld seams, it can also be used to efficiently manufacture products for the furniture industry or battery trays for electromobility. In addition, control cabinets are among the classic applications for BrightLine Scan.

Laser cutting more sustainable

At EuroBlech, Trumpf will be showing the Eco Cooler, a new, sustainable solution for cooling laser machines during the cutting process. Conventional cooling systems work with chemical refrigerants, so-called F-gases (fluorinated gases). The cooling process consumes a lot of energy, and the F-gases also pollute the environment when they are disposed of. The Eco Cooler from Trumpf cools the laser cutting machine with pure water. It also saves up to 80 percent energy for refrigeration and completely eliminates pollutants.

According to Trumpf, this solution is unique in sheet metal production to date. “Sustainability is increasingly becoming a competitive factor – also against the background of rising energy prices. To make their production fit for the future, sheet metal manufacturers should use climate- and environmentally friendly technologies. With the Eco Cooler, we support our customers in making their production more energy- and pollutant-efficient. We see the potential here to improve the ecological footprint of our entire industry and save costs in the process,” summarizes Stephan Mayer, Chief Machine Tool Officer at Trumpf.

The company developed the Eco Cooler together with its partner Efficient Energy. The solution will be available for Trumpf laser cutting machines from the 1000 to 5000 series starting at EuroBlech.

Euroblech Hall 26, Booth D51

Web:

www.trumpf.com