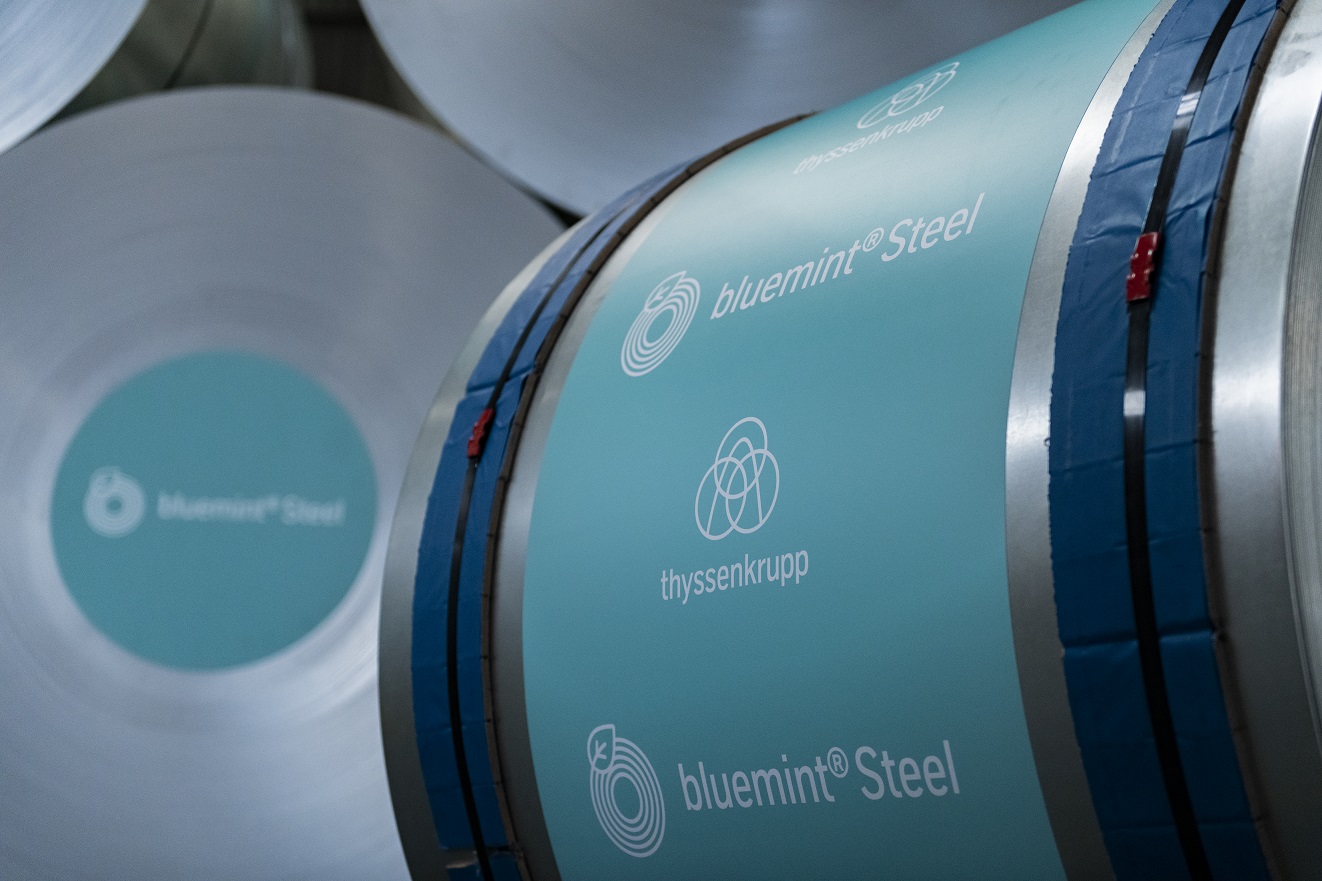

thyssenkrupp Steel and Mercedes-Benz have agreed to extend their existing cooperation to the area of CO2-reduced steel and signed a memorandum of understanding to this effect in April.

The intention is that Mercedes-Benz will receive CO2-reduced products from thyssenkrupp Steel for integration into its own fleet of new passenger cars from the end of 2026. According to current plans, the commissioning of the new direct reduction (DR) plant at thyssenkrupp’s Duisburg location should also be completed by this date.

© Mercedes-Benz Group AG

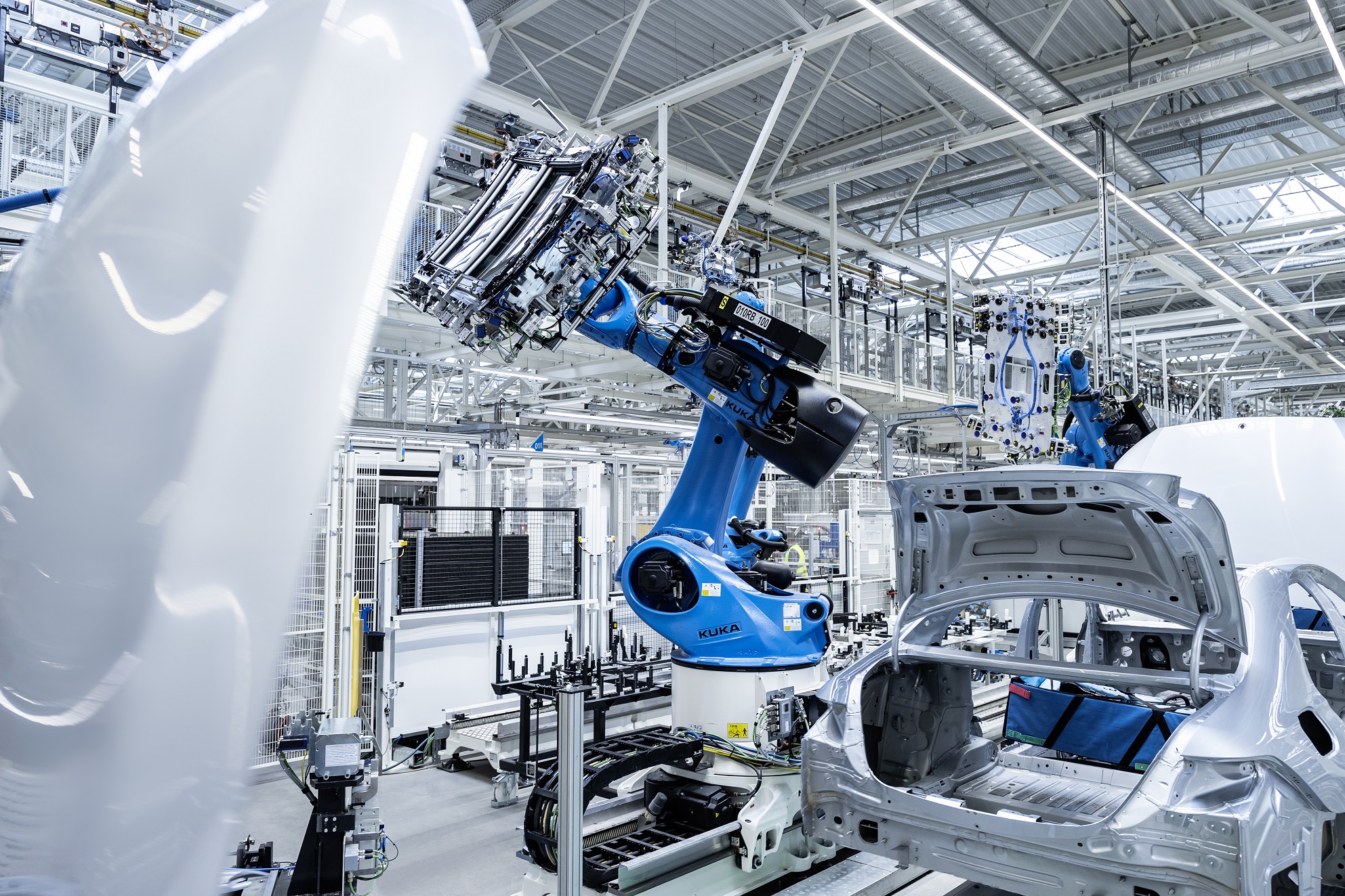

The new DR plant is a central part of thyssenkrupp’s green transformation and will be operated in conjunction with meltdown units and using “green” hydrogen. Compared with the conventional blast furnace process, this innovative technology significantly reduces production-related CO2 emissions in steelmaking while maintaining product quality – which also significantly reduces the CO2 footprint of products with a high steel content, for example in the automotive industry.

The plant thus pays tribute to thyssenkrupp Steel’s efforts to play a leading role in the “green” steel markets of the future and to support automotive customers such as Mercedes-Benz in achieving their decarbonization targets.

“Under the agreement now reached, the CO2-reduced steels from Thyssenkrupp Steel used by Mercedes-Benz from 2026 onwards will come from the new DR production route and can be supplied over the entire lifecycle of the corresponding model series. We are pleased to be able to support our customer MercedesBenz on the way to CO2-neutral car production,” says Heike Denecke-Arnold, Chief Production Officer at thyssenkrupp Steel.

Steel production at thyssenkrupp Steel is to be completely climate-neutral by 2045 at the latest. The award of the contract for the construction of the hydrogen-based direct reduction plant in combination with innovative melting units to the SMS Group in March this year is a decisive step in this direction. This marks the start of one of the world’s largest industrial decarbonization projects, which will already be able to avoid more than 3.5 million tons of CO2 per year in the future.

The direct reduction plant has a capacity of 2.5 million tons of directly reduced iron and can be seamlessly integrated into the existing steel mill thanks to its innovative concept. This allows all subsequent process steps to be maintained from the steel mill, thus ensuring consistently high product quality. This means that not only can the existing plant structure be used in an efficient manner, but customers will also continue to receive the complete, high-quality product portfolio in the usual premium quality. This makes the CO2-reduced steel produced via this production route particularly interesting for the automotive industry.