“We don’t talk sheet metal – we machine it” – according to this motto, Friedrich Blechbearbeitung from Walldürn, Germany has been designing, producing and supplying sheet metal formed parts for all industries for almost 45 years. “The market is booming. Demand from customers is high,” assures Thomas Friedrich, member of the management team, who runs the family business together with his father Michael Friedrich. When it came to planning the welding and grinding stations in a new production hall, Michael and Thomas Friedrich turned to Teka technology for extraction and opted for a flexible combi-solution in which grinding dusts and welding fumes are collected and filtered together.

© Teka

New technology for new production

The family-owned company from Baden-Württemberg (Germany) supplies all areas of the economy. On a production area of 14,000 m², a wide range of products is manufactured, from large welded assemblies for mechanical engineering to smaller, filigree components for the electrical industry.

In the new 5,000 m² hall, the company relies on state-of-the-art technologies for sheet metal processing. The area for the welding and grinding shop was expanded from 200 to 1,600 m².

“As our customers’ range of parts became larger and more diverse, we decided to enlarge and expand these areas and equip them with the most modern aspects,” says Thomas Friedrich. During planning and design, the company paid great attention to the topic of occupational health and safety: “We attach great importance to a safe and clean workplace. Only in this way can we also provide a high standard of quality and offer our total of 65 employees a motivating and tidy workplace,” assures the management.

Maximum flexibility is a must

Mainly steel and stainless steel sheets are processed there in single-shift operation, such as machine claddings, frames, fixtures and much more. The components vary from the size of a classic matchbox to a large frame for robots.

The order of the day was therefore flexibility – both in terms of the design of the welding and grinding stations and the associated extraction technology, which Teka Absaug- und Entsorgungstechnologie planned and implemented in close cooperation with its long-standing trading partner Martin Kratzer Schweiss- und Industriebedarf GmbH from Faulbach (Germany). The latter was the contact person for all questions of the customer on site and also carried out the complete installation.

Since the Walldürn-based company had good experience with an existing Teka extraction system for several welding fume workplaces, it decided to install an additional cartridge filter system of the Filtercube type with 7.5 kW power and a small footprint (800 mm wide by 800 mm deep and 3010 mm high), including a spark pre-separator, Thomas Friedrich explains further.

“The Filtercube is our all-rounder with W3 certification, which can cope with almost all tasks in the field of filtration of welding fumes and grinding dusts. The great advantage of the combi-solution installed here is that we can discharge and filter the air containing particles at the two welding tables and from the double grinding cabin via a common pipe,” explains Teka sales representative Michael Kneuer.

© Teka

Professional association compliant protection for employees

Especially during dry grinding there is often an intensive dust formation. In order to be able to collect these reliably and energy-efficiently, large-area rear wall suction units (each 1500 mm wide by 800 mm high) with dust collectors are installed at the rear of the double sanding cabin (4500 x 850 mm left chamber and 3000 x 850 mm right chamber). Heavy particles are disposed of directly in these. In this way, even the enormous quantities of pollutants produced during the processing of large components can be removed efficiently. In this way, employees are effectively protected and surfaces are kept clean.

Maximum flexibility is also guaranteed at the two welding tables. There, the system collects the air containing pollutants directly at the point of origin via extraction arms in compliance with regulations of the professional association. Particularly on the modern lifting table, the extraction arm, which is equipped with a wall bracket and can be conveniently brought to every welding point over a length of 7 metres, captures the smoke with pinpoint accuracy.

Via the pipeline, the air containing particles is first led to a spark pre-separator, where heavy and still glowing particles fall into a water bath and are extinguished. The stationary cartridge filter system with energy-saving frequency converter captures the fumes and dusts and cleans the air with a separation efficiency of almost 100 percent.

The particulate pollutants remain on the surface of the filter cartridges and fall into the container provided for this purpose during automatic cleaning.

The filter cartridges of the type Easy Clean Plus used in the Filtercube were specially developed for the dedusting of welding fumes as well as dusts. Due to their special geometry, they have a more efficient cleaning behaviour than standard cartridges and are characterised by an increased service life.

A special energetic plus: The system is equipped with a summer-winter switch. “While the filtered warm exhaust air is discharged outside in summer, it is returned to the hall in winter via a blow-out module, which significantly reduces heating costs,” says Michael Kneuer.

The investment in extraction technology paid off for Thomas Friedrich: “We are very satisfied with our extraction systems. As a result, we have clean and dust-free air in our production hall, our employees are optimally protected from particles that are harmful to their health and we save energy.”

About Teka:

Teka Absaug- und Entsorgungstechnologie GmbH has been one of Europe’s leading manufacturers of extraction and filtration systems for industry, trade, crafts and laboratories for more than 25 years. As a partner and expert for clean air at the workplace, Teka supplies international medium-sized companies and corporations from the metalworking industry, the electrical industry and laboratory technology.

Teka systems ensure healthy indoor air and thus comprehensive health protection for employees and contribute to environmental protection. The product range includes serial mobile and stationary systems, special designs as well as complex system solutions for the cutting industry and the VAC series for powerful burner-integrated extraction.

The product portfolio is supplemented by cutting, welding and flame-cutting tables as well as visual and sound protection. The Viroline series offers effective protection against viruses, bacteria and fungi and reduces the aerosol concentration of the room air.

Around 150 employees work hand in hand in development, production and sales to offer tailor-made solutions internationally with intensive consulting, service and installation services.

Almost all Teka products meet the safety requirements for the highest welding fume separation class and have been awarded the “W3” quality certificate in accordance with DIN EN ISO 15012-1.

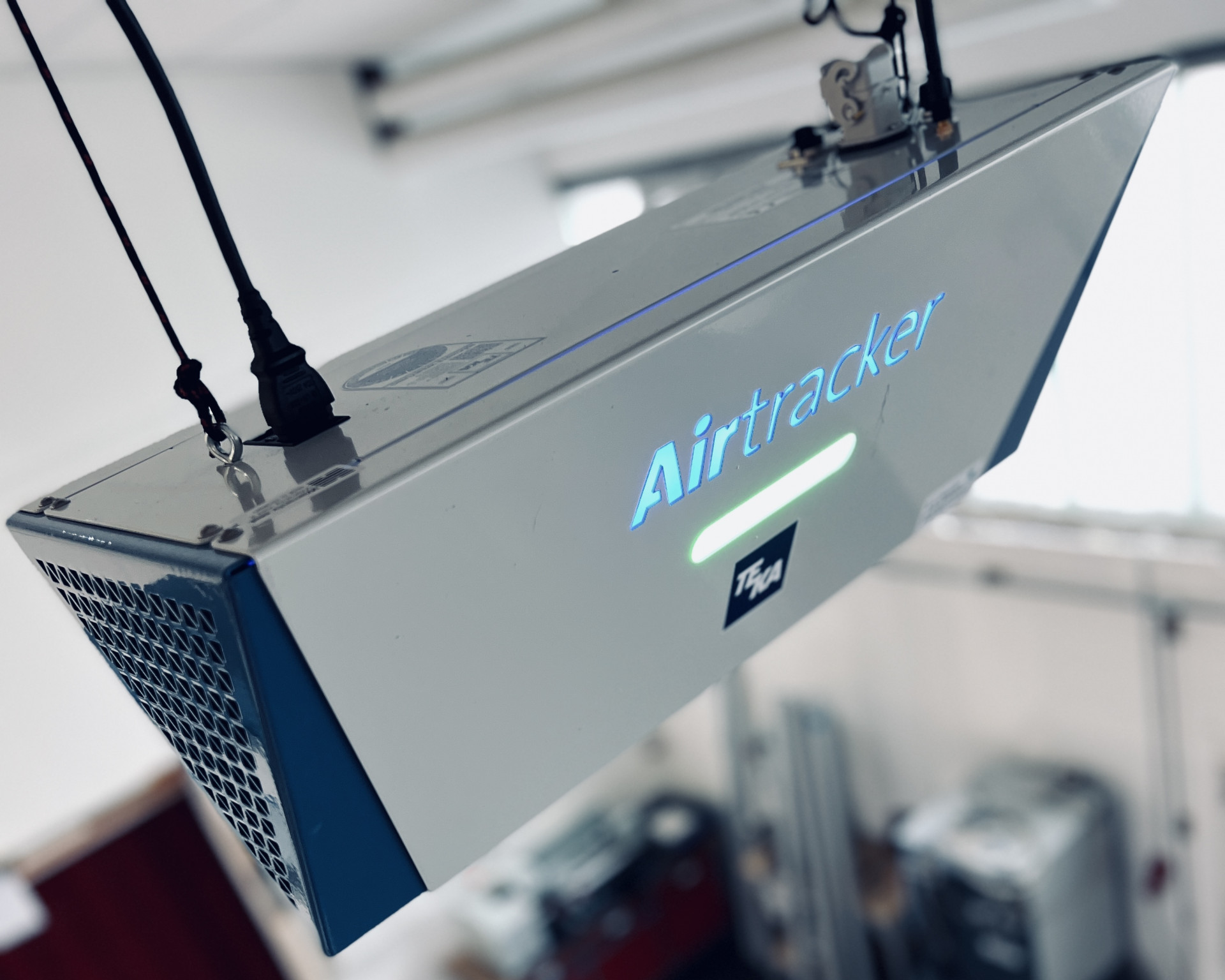

Teka is a successful pioneer in the field of Industry 4.0, as the company proves with the Airtracker family for digital room air monitoring and SmartFit boxes for plant networking. Through its active participation in the Industry Business Network 4.0 (IBN 4.0) association, Teka is committed to the development of plant standards.

Web:

www.teka.eu