Metalworkers need machines that are reliable, fast and user-friendly, that are easy to operate no matter who is operating them, machines that not only deliver performance, Q-Fin claims to deliver such machines.

As a result, the new F250 has been developed with the customer in mind and offers a solution that Q-Fin says is perfectly suited to their daily challenges. Specifically designed for deburring, rounding and finishing small sheet metal components, the F250 delivers power, speed and precision. This successor to the F200 is more than just a simple upgrade; it sets a new standard for finishing small products. With the F250, Q-Fin brings the advanced technology of the larger machines into a compact format that is suitable for the smallest products but still delivers big performance. This machine can process small parts at a speed that Q-Fin claims is five times faster than comparable finishing machines. This is due not only to mechanical improvements, but also to the intelligent software that has been integrated into the machine.

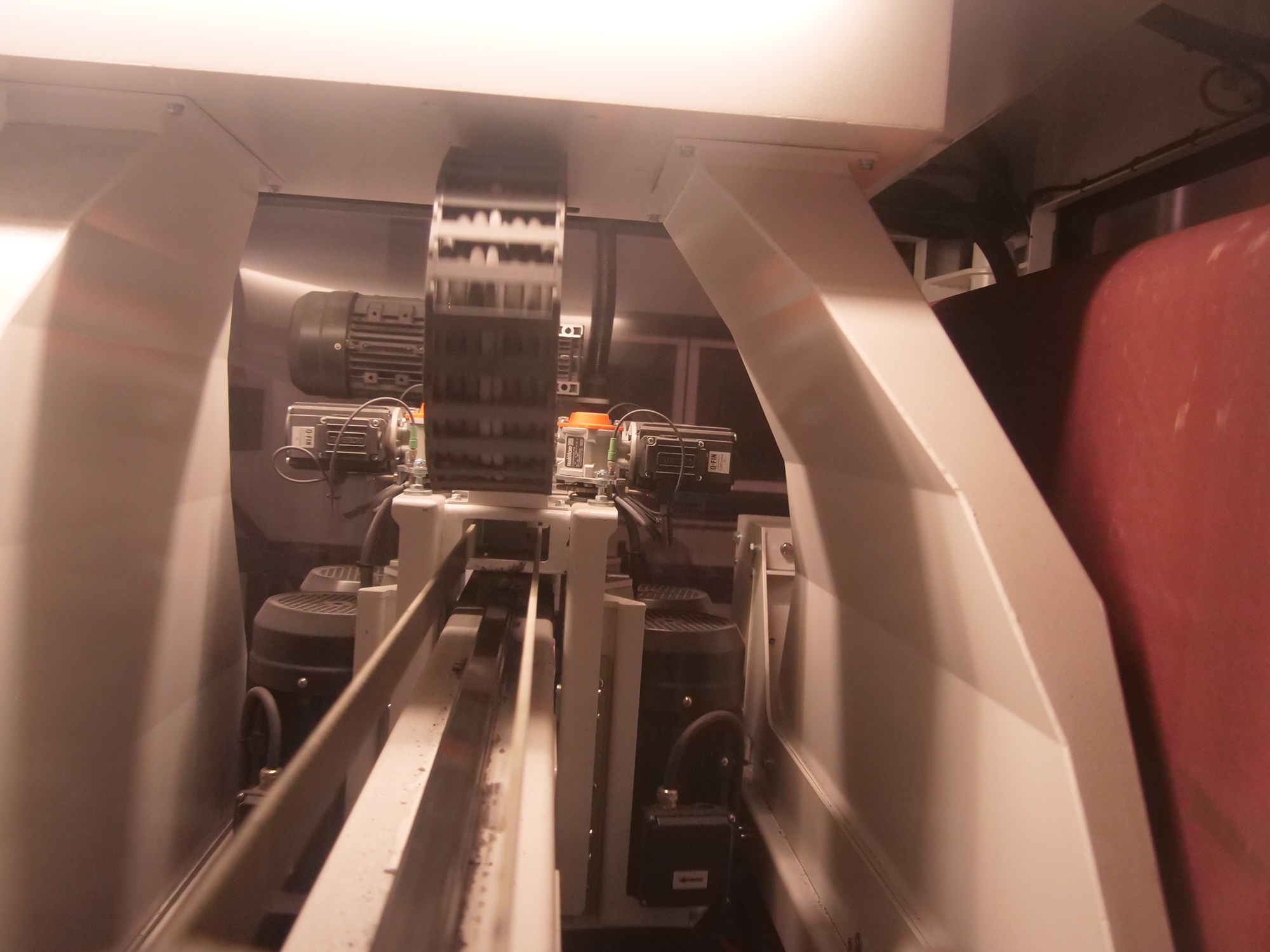

© Q-Fin

Intelligent innovation

What also sets the F250 apart is the level of control and precision that customers receive. Every station in the machine is programmable and fully software-controlled. Whether it’s sanding, rounding or finishing, users have full control. Thanks to the electronically controlled brush compensation, the disk brushes are prevented from pressing on the belt, which extends the service life of the machine. The automatic height adjustment of the sanding belt ensures that the belt is raised when not in use to prevent unwanted scratches on the product. One of the most innovative features of the F250 is the ability to calibrate the brushes at the touch of a button. This not only makes the machine more user-friendly, but also more efficient. Combined with the optional Qonnect+ system, which connects to the user’s ERP system, the F250 offers an unprecedented level of process monitoring and control. The result? Always the desired finish quality, fully tailored to the customer’s requirements. Consistent and less dependent on operator skill. It is therefore no surprise that the F250 was nominated for the prestigious Euroblech Award in the surface technology category.

User-friendliness and reliability

With a slightly wider belt width of 250 mm and a maximum product height of 100 mm, this machine offers more options without compromising on the compact design. The movable base frame and fixed table height ensure a more stable overall system and easier integration with handling systems. Thanks to the new, larger 10-inch touchscreen with modern HMI arrangement, which has been rotated by 90 degrees, the user interface is not only clearer but also more intuitive to operate. In addition, the vacuum system has been optimized so that even the smallest products – from 20 x 20 mm – remain firmly in place throughout the entire process. Products from 10 x 10 mm can be processed with the magnet system. This makes the F250 not only versatile, but also extremely reliable.

The future is now

The F250 is intended to set a new standard for finishing small sheet metal components. With its universal design, it is a machine that can grow with the customer’s requirements – from finishing the smallest cut parts to fully integrating the machine into the production line and the existing ERP system. Whether users want to optimize existing processes or expand their production capacity, the F250 could be the solution they are looking for to deburr, round and finish the smallest sheet metal parts. Web: www.q-fin.nl Euroblech Hall 12, Stand F88