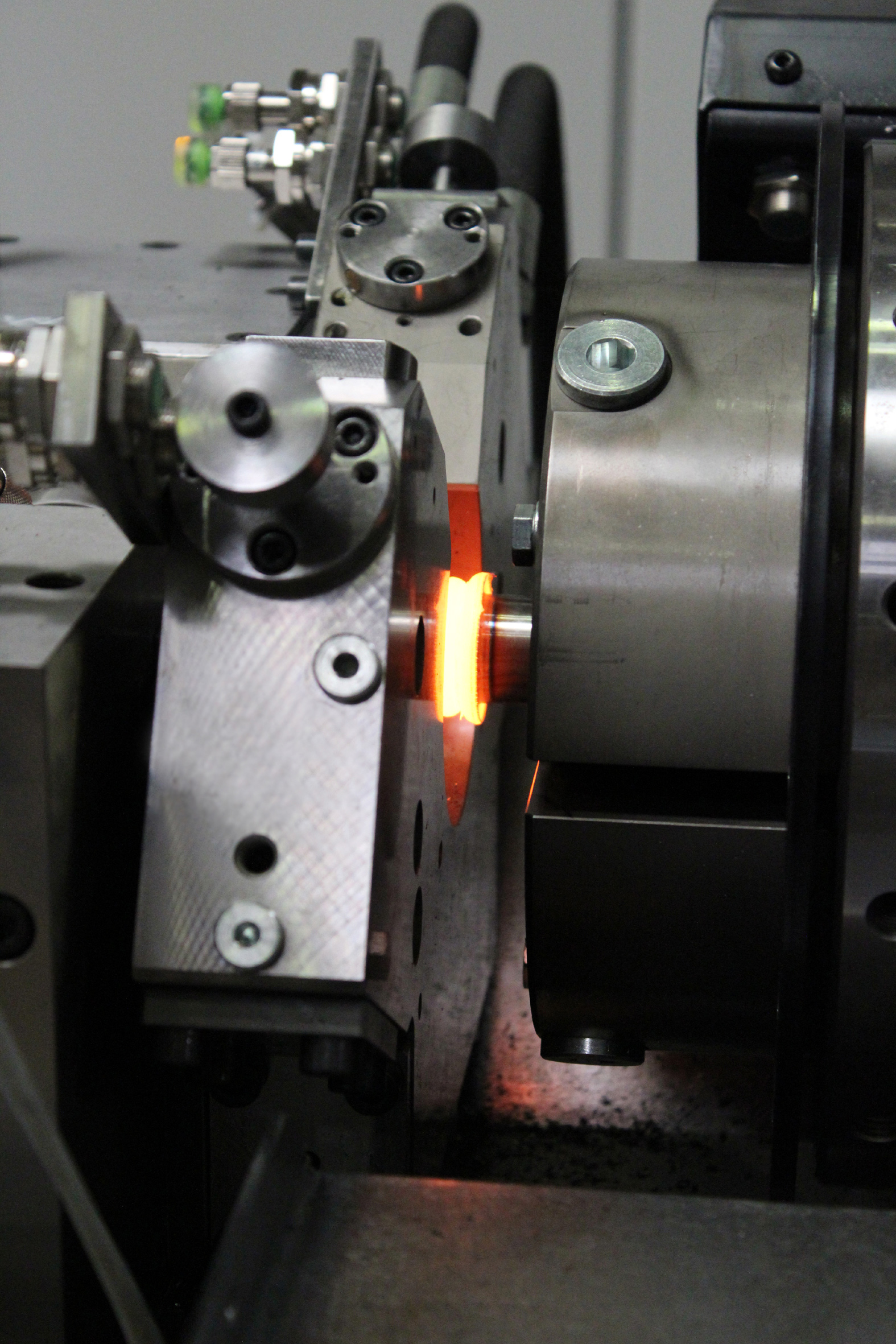

Friction and pressure – the principle of friction welding is simple and ingenious and has developed into one of the safest and most economical joining processes in modern production technology over the past few decades, even in mass production, thanks to its many possibilities and impressive advantages. Klaus Raiser GmbH & Co KG from Eberdingen has played a major role in this. As a pioneer and trendsetter, the company has been constantly driving the development of friction welding technology for 50 years.

© Klaus Raiser GmbH & Co. KG

© Klaus Raiser GmbH & Co KG

Pioneer and trendsetter in contract welding and mechanical engineering

In 1969, Klaus Raiser founded his company as a supplier for welded constructions in Eberdingen in the Ludwigsburg district. The founder then quickly discovered friction welding, which had been relatively unknown until then, and recognized its many advantages and possibilities. Friction welding technology in all its many facets has been the company’s core business since 1974 and has paved the way for Raiser to evolve from a craft business into a globally sought-after technology company that is constantly developing and advancing this powerful process. Its customers include machine and plant manufacturers as well as numerous automotive manufacturers and suppliers of all sizes. The company has grown steadily and successfully. In 2007, for example, Raiser expanded its production area by 3,700 m² with the construction of a new administration building and a new production hall in nearby Hochdorf. The processes of friction welding, mechanical processing, welded constructions, robot welding, annealing and mechanical engineering are thus once again carried out at the same location. Today, with five friction welding systems and a capacity of <5 to 1250 KN upsetting force, Raiser is one of the largest contract friction welding companies in Germany. As a modern service company, Raiser goes far beyond actual contract manufacturing, producing ready-to-install components and offering complete pre- and post-processing from a single source. In addition to extensive capacities in the field of rotary friction welding and linear friction welding, Raiser also offers friction stir welding as a service. Raiser uses the numerical simulation method of the finite element method (FEM) for both machine and process development. The process simulation allows precise analysis of the friction welding process before, during and after welding. A precise simulation can be achieved through constant comparison with real process data. State-of-the-art testing and monitoring methods ensure that all required quality standards are met. Dr. Elmar Raiser, son of the founder and current Managing Director of Klaus Raiser GmbH & Co KG, who joined the company in 1994 after studying mechanical engineering and completing his doctorate and took over his father’s “sceptre” in 2007: “Advising our customers on the optimization of joining geometries and material selection is a prerequisite for customer-specific success. Our involvement in national and international specialist committees and research projects ensures that the latest findings are always incorporated into production. In addition, our ‘Raiser Innovation Award for Friction Welding Technology’, which has been awarded every two years since 2011, sustainably promotes research and development in the field of friction welding. A particular aim of the award is to support young talents from science and industry and to encourage them to present their innovative new and further developments in all areas of friction welding.”

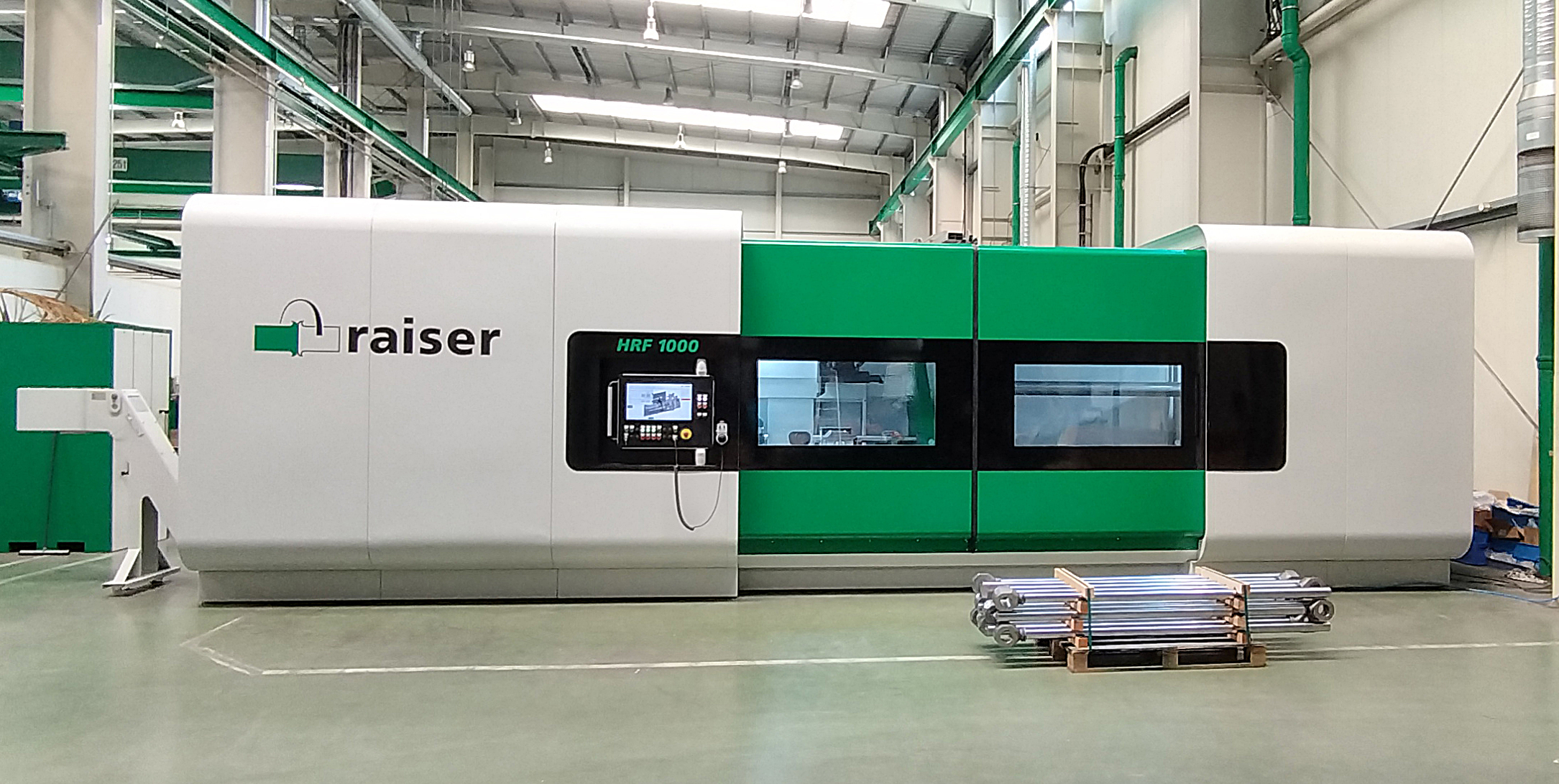

Sophisticated friction welding machine concept

Raiser has incorporated its decades of experience with the friction welding process into the development and construction of friction welding machines. Important chapters in the company’s history include Raiser Engineering GmbH & Co. KG, founded in 2012 for the production of special machines. This provides a complete service from planning, CAD design, simulation and optimization to construction and assembly – all from a single source. In 2021, Raiser takes over the friction welding division of Symacon Maschinenbau GmbH, thereby expanding its product portfolio in the field of friction welding machines. This expansion of expertise makes Raiser a full-service provider for friction welding – from process development and contract manufacturing in small and large series to the finished machine. Today, Raiser’s machine portfolio includes machines with an axial force of 5 to 3,000 KN. This ranges from standard machines to special systems tailored to customer requirements – as a stand-alone unit or as a production unit integrated into a production workflow. Elmar Raiser: “Our extensive experience and know-how in the field of friction welding technology are consistently incorporated into the development of friction welding machines. Passing on decades of experience gives our customers a head start in the use of friction welding technology. For both linear and rotary friction welding machines, the focus is on optimally adapting the machine to the component to be produced and to individual customer requirements. Our aim is to manufacture the machine optimized for the respective application. We make use of a large modular system of standard components. The modern machine concept, which is tailored to each individual case, enables the friction welding machine to be integrated into upstream and downstream production processes.” The use of proven and standardized components ensures high machine availability and a long service life. Raiser consistently relies on servo-electric feed drives to apply the axial process forces. In addition to the many process-related advantages such as length accuracy, concentricity and reproducibility, this also results in a large energy-saving potential compared to classic hydraulic friction welding machines. In addition to automation concepts for parts feed and removal as well as pure process technology, the machine layouts always focus on ease of operation, ease of service and maintenance as well as quick changeover options. Raiser also places great emphasis on the removal of the welding bead created during friction welding. A wide variety of removal methods such as turning, milling and punching are available for both the outer and, if necessary, the inner bead. Modern CNC turning and milling units enable precise pre- and post-processing of the parts immediately before or after the friction welding process.

© Klaus Raiser GmbH & Co. KG