At Q-Fin, they believe in innovation. According to its developers, the new F250 is set to become the new benchmark for finishing small sheet metal parts. At Eurobleche, the F250 was presented with the Euroblech Award in the surface technology category.

The F250 is the successor to the F200 and translates the technology of the larger Q-Fin machines into a compact and versatile format specifically for deburring, rounding and finishing small metal parts. This concept convinced the jury and the public with its extensive automation and high degree of user-friendliness. In a public vote, the F250 was chosen as the winner in the surface technology category from over 70 entries.

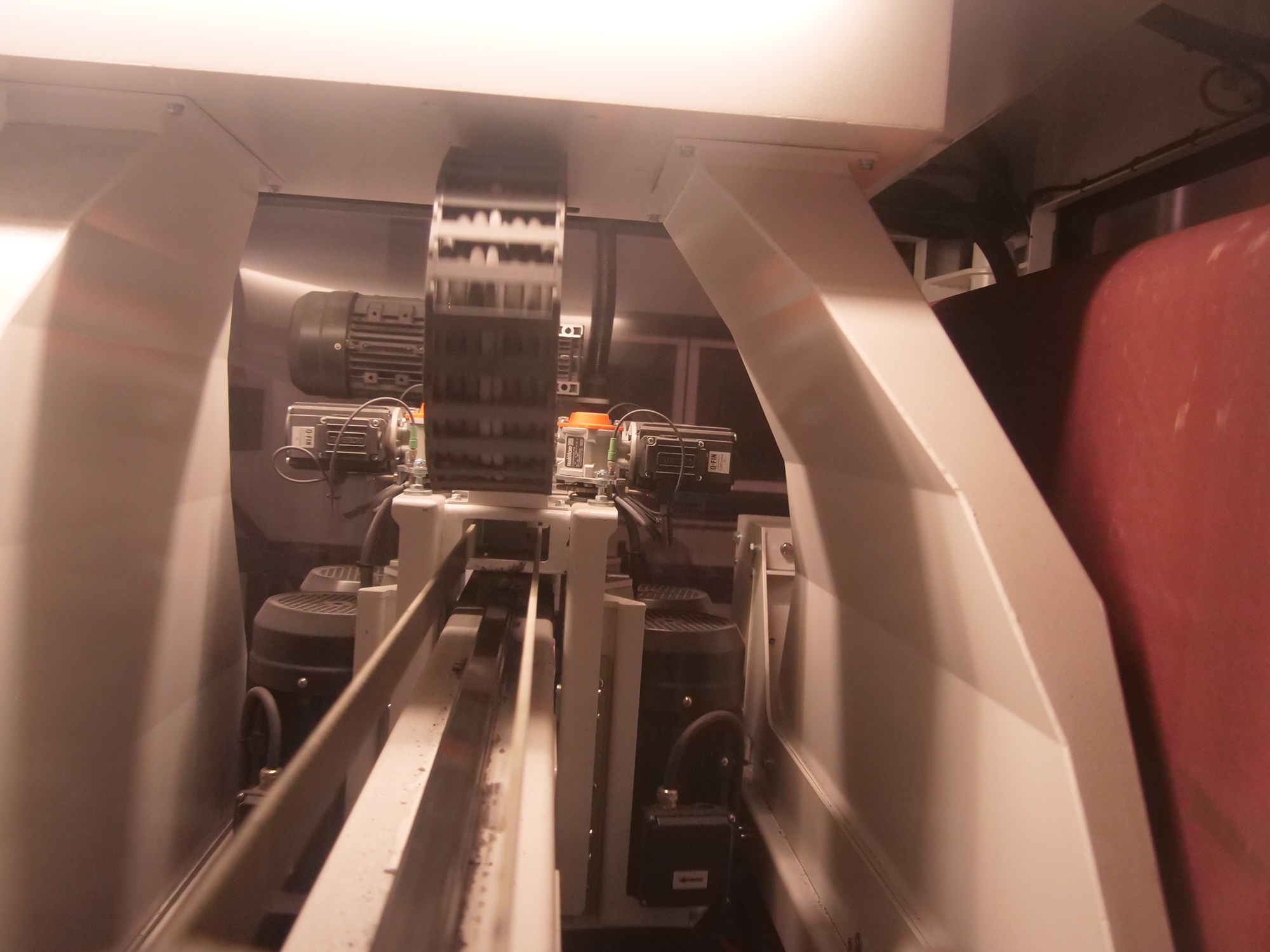

Power, precision and control in a compact format

The F250 was developed with the user in mind. With a 250 mm belt width and a maximum product height of 100 mm, the machine offers comprehensive options for deburring, rounding and finishing small sheet metal parts. Each processing station can be fully software-controlled, giving the user complete control. The innovative vacuum system ensures that even the smallest parts from 20 x 20 mm remain securely in place, while the magnet system ensures safe processing of products from 10 x 10 mm. A fixed table height and a movable inner frame also contribute to stability and make it easier to integrate the F250 into automation solutions. Thanks to the Qonnect+ software, the F250 can be connected to ERP systems for comprehensive process monitoring. In addition, the automatic height adjustment of the sanding belt optimizes the process by preventing scratches on the products when the machine is idle, and the electronic brush compensation extends the service life of the machine by preventing the brushes from pressing on the belt. A modern 10-inch touchscreen ensures intuitive and clear operation.

A new standard for surface treatment

“The F250 proves that a compact machine can deliver on all levels,” says Joost Kouwenbergh, Business Officer at Q-Fin. “We have listened well to our customers and this machine seamlessly meets their requirements for a versatile, efficient and user-friendly solution for smaller sheet metal parts.”

Web:

www.q-fin.nl