From the finishing machine to the fully automated handling process: Industry 5.0 is increasingly taking shape at Q-Fin Quality Finishing Machines. At Blechexpo 2025, the sheet metal processing industry will discover the added value of complete automation, which is accessible to everyone.

Q-Fin has been developing, building and supplying solutions for deburring, rounding and finishing sheet metal parts since 2013, including comprehensive handling solutions to increase the performance of finishing machines. Conveyor belts for a seamless material flow, cobots and robots for precise automated handling and a versatile turning station for workflow optimization have been developed to streamline the finishing process, reduce labour costs and ensure consistent quality.

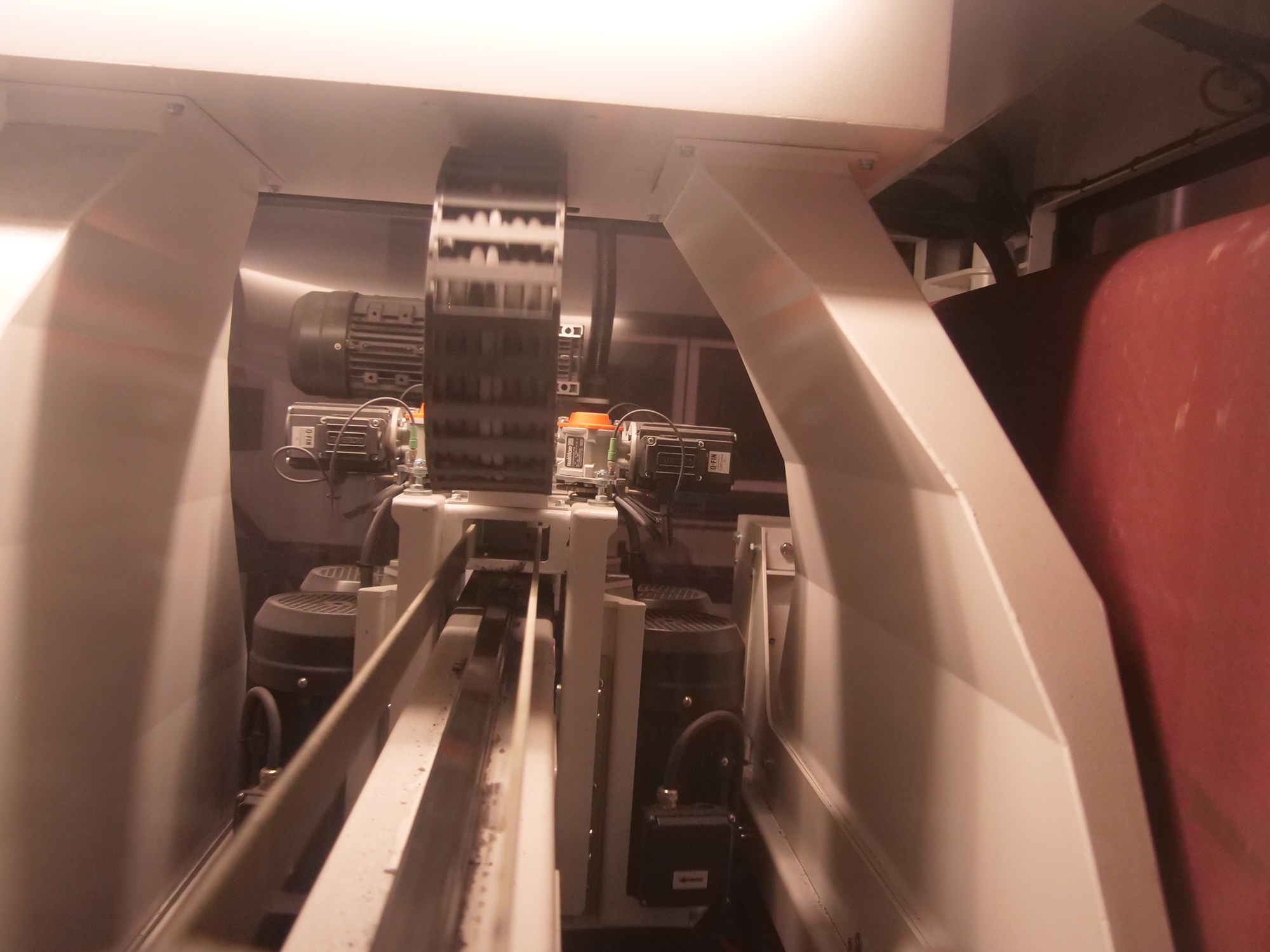

© Q-Fin

Modularity as the key to growth

At Blechexpo, however, everything at Q-fin revolves around the foundation: the robust and reliable finishing machine. Visitors will experience how this basis can be modularly expanded into a fully automated production line with the Q-Bot. Industry 5.0 is tangible and feasible for every sheet metal worker.

Q-Fin’s modular approach means that every solution is developed entirely in-house and prepared for installation at the customer’s premises. From the software to the handling and robotics, everything is realized by the Q-Fin team. This not only creates maximum flexibility, but also trust. The showroom in Bergeijk features a 52-metre-long installation with integrated handling solutions over 14 meters. “The competitive advantage that this fully automated line gives our customers is unprecedented. Our machines are designed for growth and we are at every customer’s side to help them continue to optimize in the future.”

Handling under control

Speed can only be achieved if the handling is right. Q-Fin will be demonstrating how to achieve this live at Blechexpo. The F250 is perfect for ultra-fast deburring, rounding and finishing of small, flat sheet metal parts up to 250 mm wide. Combined with a Twister for finishing on both sides in a single pass and a Q-Bot for automatic loading, the result is a completely manual, labor-free workflow ideal for continuous 24/7 operation.

“Handling around the machine is often the bottleneck when it comes to scaling,” says Patrick van Scherpenseel. “We solve this problem. Our Q-Bots take over the manual work, increase speed and guarantee consistent quality. Customers who work with them no longer want to do without them. Above all, we show that full automation is not just for large companies. It is achievable for anyone who wants to use space and personnel more efficiently. Our efficiency gains can be found in every machine – and in every software configuration.”

Ten years ago, Q-Fin exhibited at Blechexpo for the first time. Numerous awards and product innovations later, the company continues to set standards – for organizations that see simple production processes not as a hurdle, but as an opportunity for differentiation.

Web:

www.q-fin.nl