Just in time for its 25th anniversary, Aquatec is automating edge processing. Steel, stainless steel and aluminum can now be rounded reproducibly with a defined radius 2+ – without the effort of previous manual work.

“We take on projects that others don’t dare to tackle – especially when it comes to large and complex components. We can cover the entire production spectrum, from the raw material to the finished product.” The statement by Lucia Esposito, Managing Director of Aquatec Master in Metal GmbH from Emmerich, points to the special role of this job store. Aquatec is a global leader in unusual projects. The company realized complex façade constructions with several hundred tons of aluminium components and assemblies for modern rail vehicles made of welded aluminium profiles. In addition, Aquatec supplied several thousand tons of duplex steel for spectacular architectural roof and dome constructions.

© Fecht

Highest standards of precision and surface quality

Anyone realizing projects of this size and complexity relies on the highest standards of precision and surface quality. The requirements for deburring are correspondingly high: cleanly rounded edges ensure safe handling, exact fitting accuracy and permanently adhering coatings.

Until the beginning of 2025, however, deburring was mainly done by hand – a labor-intensive and unhealthy process with a considerable risk of injury. “For a current project, we urgently needed to prepare components with a radius of 2 for subsequent painting. It was not economically feasible to do this manually,” reports Johannes Dicks, Design and Project Management at Aquatec. The search for an automated solution ultimately led to Q-Fin B.V., a manufacturer from the Eindhoven region that is breaking new ground with innovative deburring machines.

Decision under time pressure

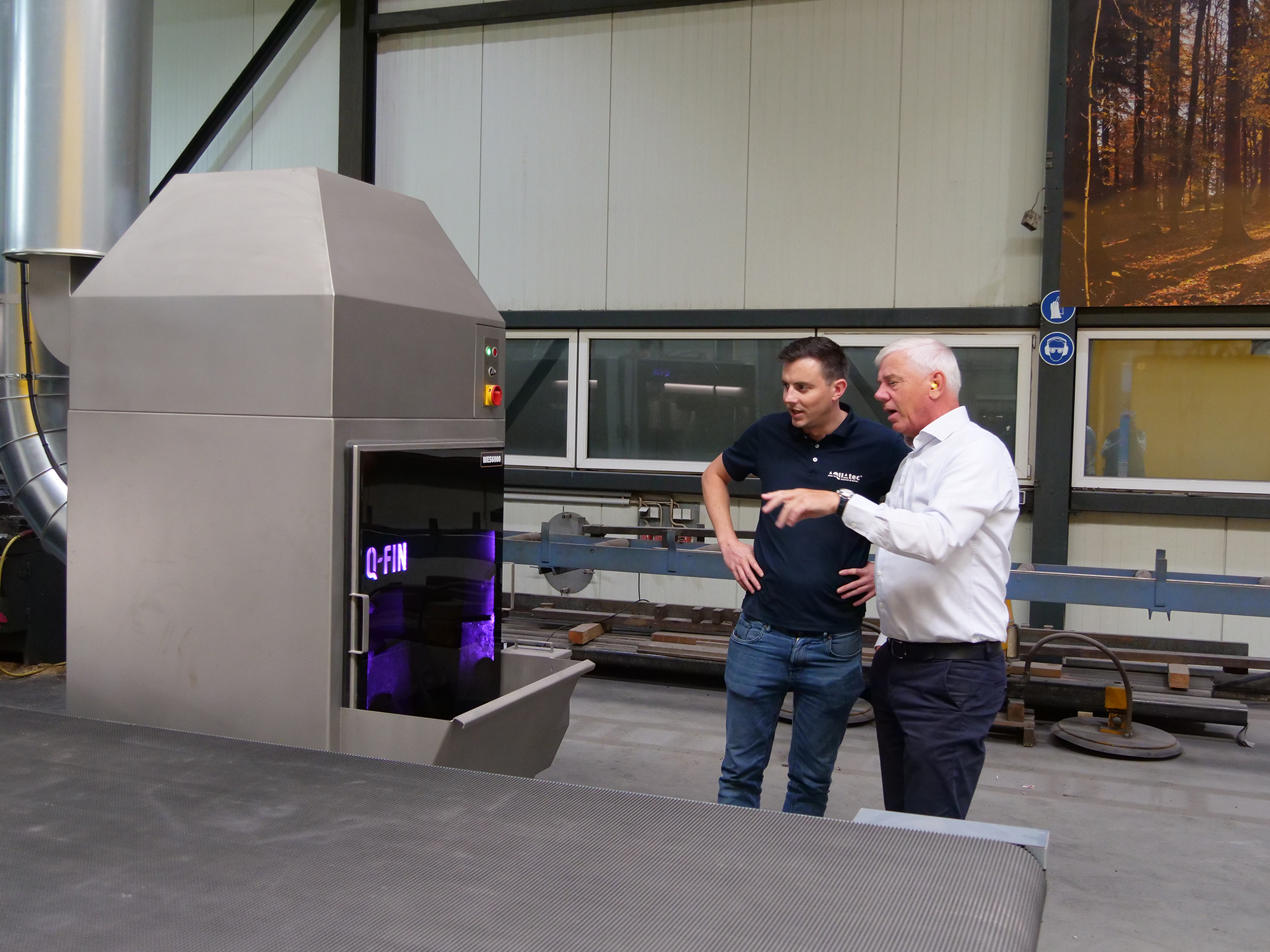

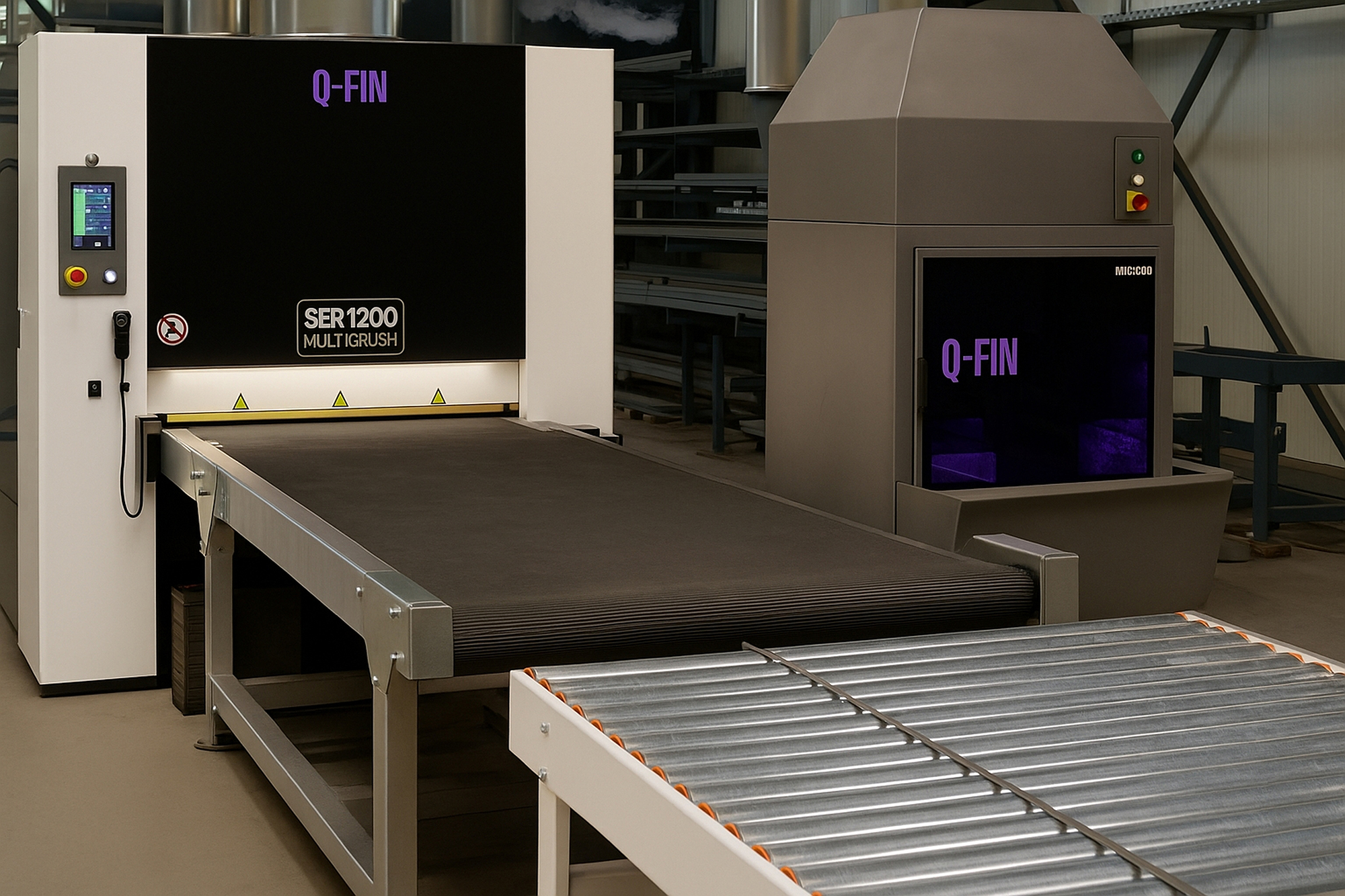

Within a few weeks, Aquatec decided to invest in a SER1200 Multibrush Combi, an all-in-one deburring machine. It is a real all-rounder, as it can deburr and round sheet metal parts up to 1200 millimetres wide and give them an even finish – regardless of whether they are made of steel, stainless steel or aluminum. With this series, Q-Fin has developed a new type of deburring machine that breaks completely new ground in the processing of sheet metal. To see the possibilities of this technology for himself, Dicks and his team traveled to the plant in Bergeijk on a Saturday. Q-Fin opened the factory gates and provided a demonstration machine for trial work with Aquatec components. The results were immediately impressive – and just three weeks later, in February 2025, the new system was ready for use in Emmerich. The new machine replaced manual reworking and has since enabled reproducible quality for steel, stainless steel and aluminum parts.

© Fecht

Employees from 16 nations: ease of use required

In addition to the surface quality, the ease of operation was also convincing. Mohamed Faresse, an employee of Moroccan origin, immediately got to grips with the system. “After a short briefing, he was able to deburr the first parts without any problems,” reports Dicks. This is a decisive advantage for a company with employees from 16 different countries. Language barriers and different educational backgrounds make qualification difficult on a day-to-day basis. “For a multicultural team with different educational backgrounds, intuitive operation is a major advantage,” adds Dicks. Q-Fin attaches great importance to this aspect. “During demonstrations, we often ask customers to try it out for themselves. Many are surprised at how intuitive the controls are,” explains Fred Post, Account Manager Germany at Q-Fin.

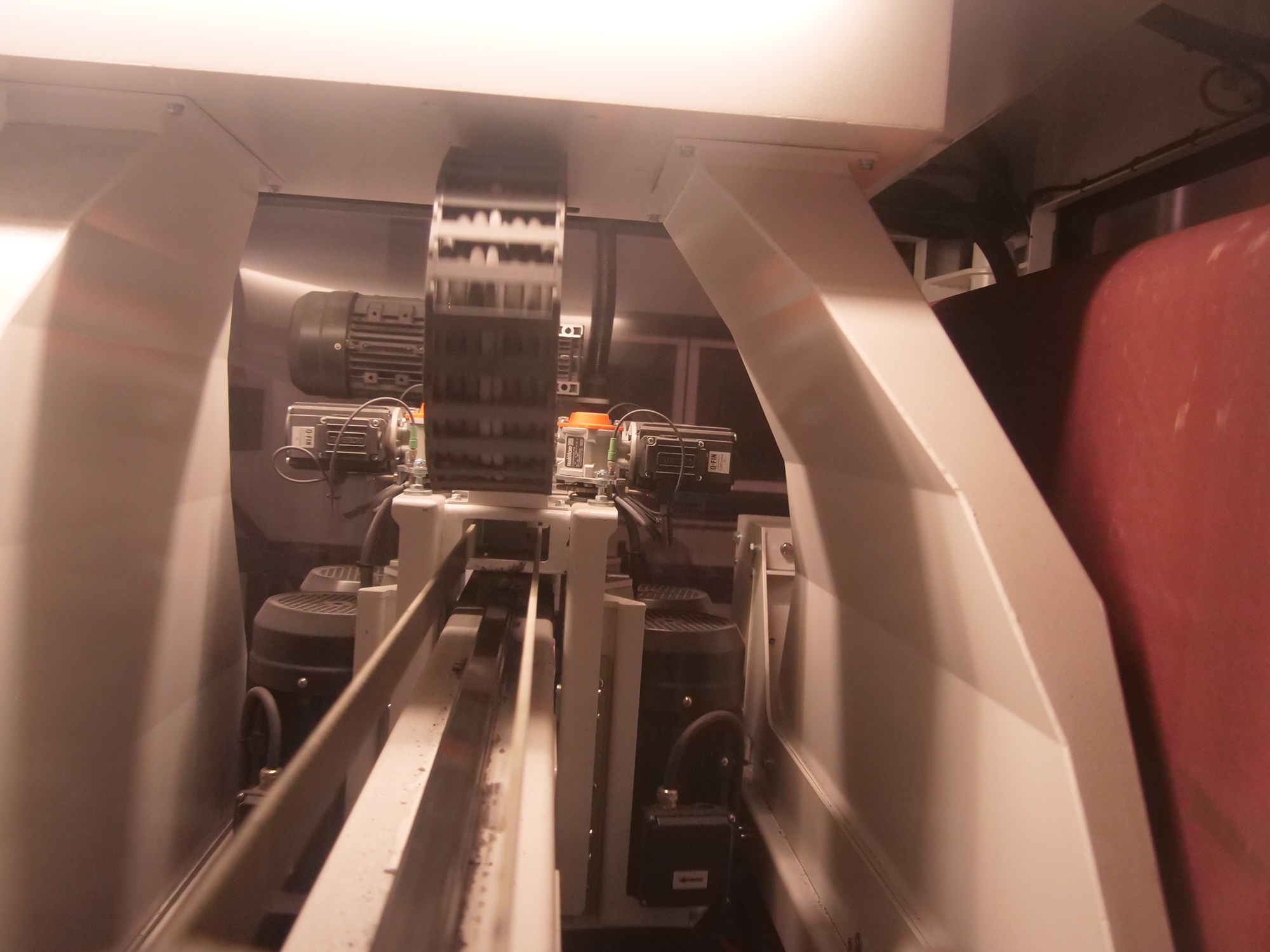

The SER1200 Multibrush Combi combines several processing stations: a sanding belt unit, two disk brush units and a Multibrush unit with six cross-rotating round brushes. With this setup, deburring, rounding and different finish variants can be realized in a single pass. This is interesting for a job store like Aquatec, which often processes different components alternately on an order-oriented basis. This is supported by the combined vacuum and magnet system, which fixes steel, stainless steel and aluminum parts. The non-productive times are short, as the changeover to a new material takes a maximum of 15 minutes.

Extraction and safety

The machine is connected to a WES6000 wet filter system. It separates sanding dust in the water and thus prevents fire and explosion risks. With an air output of 6000 m³/h and a water consumption of around 7 l/h, no filter material is required; the separated chips can be recycled.

The practical nature of the concept is also evident in the maintenance. Q-Fin not only took care of the installation, but also trained the Aquatec team directly on site. A digitally stored maintenance plan supports the operators in their day-to-day work. “Basically, it is enough to lubricate the grease nipples regularly and remove the residual dust with compressed air,” explains Post. Additional filters do not need to be changed as the wet system works solely with tap water. This keeps maintenance costs low and operating costs low.

The system is used both for large-format components up to 16 m long with roller tables and for smaller series in throughfeed. Daily outputs of up to 400 parts are possible. In addition to stainless steel, Aquatec also processes duplex, aluminum and steel. “The machine ensures consistent quality and relieves employees of manual work steps,” says Dicks. “Every manual processing step carries the risk of differences – with the machine, on the other hand, we have consistent quality and need fewer staff.”

© Fecht

Future-proof: easy expansion

With the SER1200 Multibrush Combi, Aquatec has not only eliminated a current bottleneck, but has also opened the door to future-oriented production. The modular concept of Q-Fin allows expansions right up to fully automatic assembly. “We make complete solutions for automatic assembly – and we are already taking the next steps with robot technology,” emphasizes Post. A practical example shows where the journey can take us: Thanks to automation, a sheet metal processor was able to significantly reduce its personnel requirements in shift operation and considerably increase efficiency. For Aquatec, the new machine may just be the first step.

Technical data – SER1200 Multibrush Combi with WES6000

Stations: Sanding belt, 2 × disk brushes (automatic brush calibration), Multibrush (6 round brushes), oscillating, Quick-Lock quick-change system

Processing: Deburring, rounding (radius 2 +), sanding patterns, finishing

Workpiece sizes: up to 1200 mm wide, up to 150 mm high, min. 80 mm × 80 mm (stainless steel and aluminum) or min. 50 mm x 50 mm (steel), 0.6 mm minimum height

Conveyor belt: 0.3-10 m/min; load up to 300 kg/m¹

Fixation: vacuum and magnet system (Combi)

Abrasive change: stainless steel → steel 0 min; steel → stainless steel max. 15 min Cleaning

Electrical: 400 V, 30-32 kW, CEE 63 A

Application AQUAtec: Large parts up to 16 m, small series in throughfeed, up to 400 parts/day

Facts & Figures

Founded: 2013 by Anton Bax & Koen de Waard in Bergeijk (Eindhoven area, NL)

Company form: BM Holding (part of a group with four companies including Laserparts, RVS Finish, Bax Metaal)

Employees: around 210 (as of 2025)

Origin: originated from the in-house requirements of a sheet metal processor who could not find a suitable deburring machine on the market

Philosophy: very innovative, at least two new developments per year; practical, as the group processes sheet metal itself. Highly innovative

Products and services: Machines for deburring, rounding, surface finishing of sheet metal parts; high reproducibility, Industry 4.0 ready QHS: Handling Solutions (automation)

Location: Company headquarters and production in Bergeijk (NL)

Author:

Nikolaus Fecht, specialist journalist from Gelsenkirchen

Hall 5, Stand 5407