With 3D printers and lasers from Trumpf, aerospace companies can save a lot of weight in aircraft manufacturing and produce more efficient engines.

“Laser technology and 3D printing are key technologies for the production of sustainable aircraft. With technology and know-how from Trumpf, the aviation industry will be able to put electric-powered aircraft and air cabs in the air in the near future. We can support the aviation industry with our years of battery and e-mobility expertise in automotive manufacturing,” expects Richard Bannmüller, CEO of Trumpf Laser- und Systemtechnik GmbH. The high-tech company presents its manufacturing technology for the aerospace industry at the leading trade show Paris Air Show.

© Trumpf

Laser technology enables emission-free flying

Almost all aircraft manufacturers and suppliers are working on climate-friendly aircraft. Many are already pursuing concrete concepts for the electrification of aircraft engines. For aviation, manufacturers must develop particularly lightweight, safe and reliable batteries and electric motors. “Our experience in manufacturing electric drives and batteries in the automotive industry can be transferred to many areas of aviation. With our manufacturing technology, we can make an important contribution to the decarbonization of aviation,” continues Bannmüller.

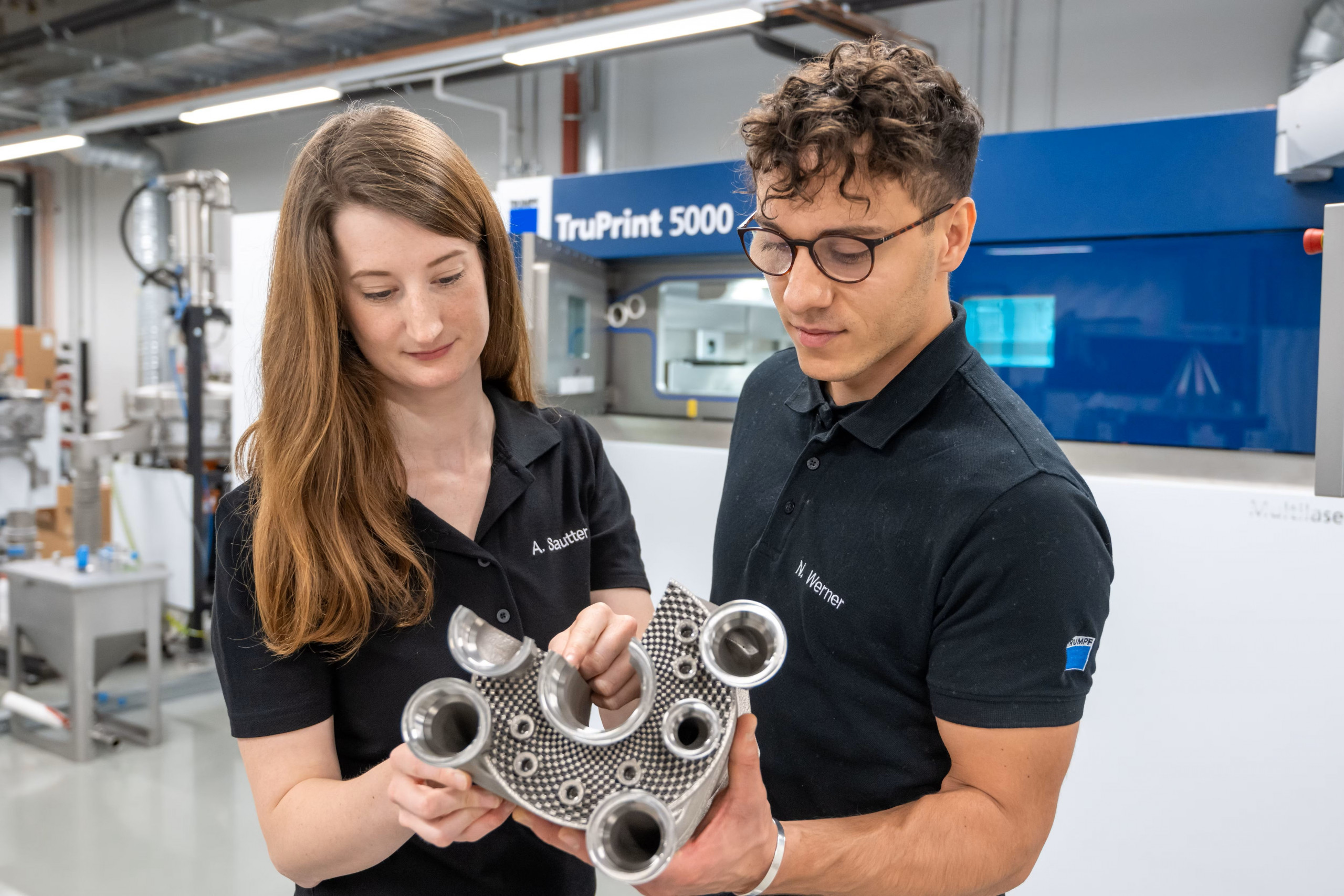

Trumpf manufacturing technology ensures greater efficiency

Trumpf works with many OEMs and suppliers in the aerospace industry. To manufacture particularly efficient rockets and thrusters, companies use lasers from the high-tech company to cut and weld metal alloys. To make drives lighter and more efficient, the aerospace industry is using 3D printers from Trumpf.

As a result, manufacturers produce lightweight thrusters that are at the same time particularly optimized for efficiency. “Trumpf is a reliable partner for the aerospace industry with its manufacturing expertise. The product life cycles in the aerospace industry are very long. Here, we support our customers for many years with service and spare parts for our machines,” promises Bannmüller.

Repair instead of buying new: Repair with laser buildup welding

The aviation industry also benefits from technology from Trumpf when it comes to maintenance. For example, instead of re-procuring damaged engine blades, airlines repair them using laser cladding (LMD). The laser creates a molten bath on the surface of the engine blade and precisely melts the simultaneously fed metal powder according to the desired shape. By repairing high-cost components, the aerospace industry can save up to 80 percent in costs compared to purchasing new ones.

Facts & Figures

Trumpf offers manufacturing solutions in the areas of machine tools and laser technology. The company is driving forward the digital networking of the manufacturing industry through consulting, platform and software offerings. Trumpf is considered by many to be the technology and market leader in machine tools for flexible sheet metal processing and in industrial lasers.

In 2021/22 the company generated sales of 4.2 billion euros with around 16,500 employees. With more than 80 subsidiaries, the Group is represented in almost all European countries, in North and South America, and in Asia. Production sites are located in Germany, France, Great Britain, Italy, Austria and Switzerland, in Poland, the Czech Republic, the USA, Mexico and China.

Web:

www.trumpf.com