On April 10, 2025, Misati, Fagor Arrasate, Ribinerf and Azolgas, which are among the technology leaders in sheet metal forming with transfer systems, will be hosting the specialist conference “Efficient use of transfer systems in press shops” in Meerane, north of Zwickau.

The event, organized by Azolgas, Fagor Arrasate, Misati and Ribinerf, will bring together industry experts to discuss key aspects for optimizing productivity in sheet metal forming with transfer systems. During the conference, these companies will present innovative strategies to increase productivity, reduce investment costs, avoid incidents and reduce downtime during sheet metal forming on transfer systems.

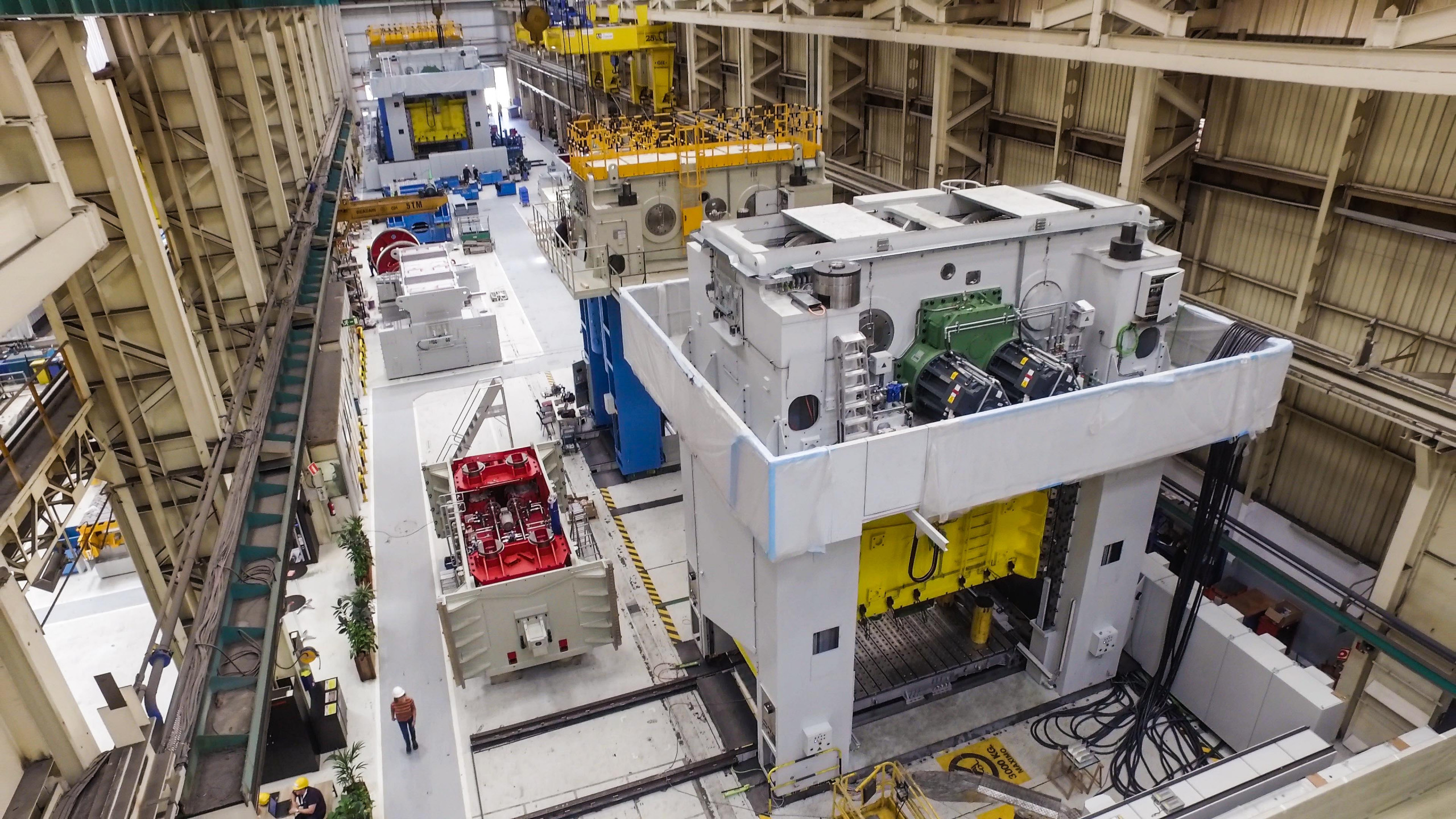

Gerald Schulz from Fagor Arrasate will focus on how to maximize production on transfer systems. He will analyze how the latest technologies can optimize press lines to achieve higher production with minimal resources and explain how fully automated transfer systems optimize cycle times, improve material flow and adapt to different workpiece geometries with high precision. In addition, participants will learn intelligent programming strategies that enable transfer presses to reach their maximum performance without compromising process stability or part quality.

For Ribinerf, a company of the Fagor Arrasate Group, Estibalitz Arregi presents the concept of complete automation at the end of the line, with real-time quality control through machine vision, robotic part handling and intelligent stacking solutions. He will explore how advanced machine vision technology enables the detection of defects at high speeds and how robotic component handling solutions can optimize the sorting and stacking of components, ensuring a smooth flow of downstream operations.

Juan José Sánchez from Misati talks about the latest developments in the automation of transfer presses to achieve production rates of over 35 strokes per minute, such as the mini grippers with tilting arm for maximum acceleration and solutions for component rotation on all three axes. He will also discuss services to reduce downtime on the press during commissioning and to calculate production and cycle diagrams in advance for an initial amortization analysis of transfer projects.

Finally, Ignacio García Acha, General Director of Azolgas, will present developments in the field of gas springs for sheet metal forming, innovations in materials, product design and mandatory product safety in accordance with VDI regulations. In addition, various product concepts such as decelerating and controllable gas springs and the latest technological development of sensorized springs for Industry 4.0 will be addressed. Finally, the use of hydraulic cylinders and the innovation of self-sufficient cutting shock absorbers for forming materials with high sheet thickness or high elasticity limits will be discussed.