At Blechexpo 2025 in Stuttgart, Lantek, a leading global provider of software solutions for the sheet metal working industry, presented its software update V45 with many innovations, including KAI – the AI assistant.

For the Smart Factory, the introduction of the Lantek V45 software version marks another major step forward in digitalization and efficiency. Its key focus areas are artificial intelligence (AI), cross-platform integration and advanced connectivity. Highlights include the introduction of KAI, a new generation of AI-based services and functions. Developed by Lantek, KAI will be introduced with the software update as a new assistant available across multiple applications. It supports users in their daily tasks and paves the way for a future in which artificial intelligence plays a central role in industrial software.

Improvements to Lantek Bend and Lantek Stackmaster

Version V45 also includes an edition of Lantek Bend bending software that is fully integrated with Lantek’s cutting, MES and ERP solutions – both in terms of its functionality and data structure. This ensures improved consistency and traceability throughout the production process. In addition, Lantek has completely redesigned its palletizing module Lantek Stackmaster. This follows the significant technological developments in sheet metal processing machines with palletizing equipment. The redesign allows the Lantek software to fully meet the latest requirements for the module and seamlessly integrate the material flow into production management workflows.

Another important innovation that Lantek will be presenting at Blechexpo 2025 is the further development of Lantek A2N (Assembly to Nesting). Since its launch at Euroblech 2024, it has been in huge demand as it can produce 3D sheet metal parts and assemblies in minutes, which previously sometimes took hours. The V45 software update now comes with improvements in usability and unwinding accuracy through the use of bending tool data. These upgrades further enhance A2N’s ability to optimize and accelerate the transition from design to nesting and manufacturing.

Advantages for steel construction

In the 3D CAD/CAM sector, Lantek announces the launch of its native connector with Strumis. The steel fabrication management software is fully integrated with Tekla for 3D design and is now directly connected to Lantek Flex3D via the connector for a complete workflow. In addition, Flex3D version 45 comes with a major upgrade of its nesting system, which enables optimal material utilization, significantly improving efficiency and thus reducing production costs.

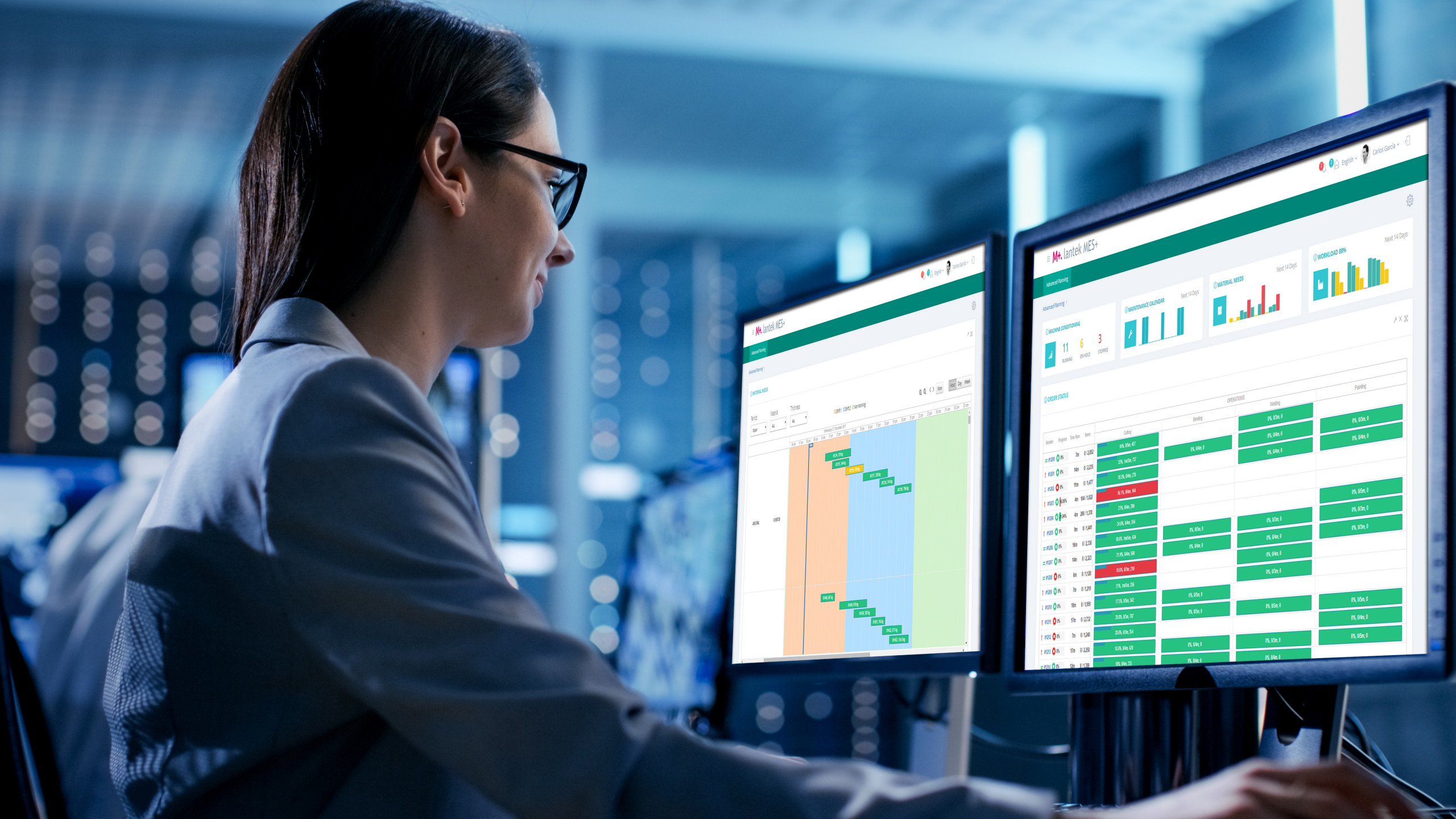

The new version V45 also integrates the new generation of the production planning tool into Lantek MES. With a complete visual web interface, it offers greater transparency and accuracy in delivery times and resource utilization. It also comes with new developments in intermediate stock management and enhancements in machine connectivity for all types of manufacturing centers through Machine Connectivity. In addition, there are dozens of new features that consolidate Lantek’s position as a benchmark for the digitalization of the sheet metal industry.

“Blechexpo is the ideal opportunity to get to know Lantek’s vision for the future of sheet metal production,” says Christoph Lenhard, head of the German office responsible for Germany, Austria and Switzerland. “With the introduction of KAI, the integration of our solutions and the continuous development of our products, we are enabling our customers to achieve a new level of competitiveness and efficiency in a rapidly changing industry.”

Background

Lantek is a multinational company that is a leader in the digital transformation of companies in the sheet metal and metal industry. With its patented intelligent manufacturing software, it enables the networking of production facilities and turns them into smart factories. The range of services is completed by CAD/CAM/MES/ERP software solutions for manufacturers of sheet metal parts, tubes and profiles with different cutting (laser, plasma, oxyfuel, waterjet, shearing) and punching processes.

Founded in 1986 in the Basque Country (Spain), one of the most important European centers for the development of machine tools, the company enables the integration of sheet metal and metalworking technologies with state-of-the-art software for production management. Lantek is currently the market leader in the sector, thanks to its innovative expertise and consistent internationalization strategy. With more than 36,000 customers in over 100 countries and 22 of its own offices in 16 countries, the company has an extensive network of distributors with a global presence.

Hall 1, Stand 1111