Until not so long ago, interaction between departments and with customers was based on phone calls, meetings and many, many papers with data manually entered into computers – sometimes multiple times for different systems – and then filed somewhere. This was costly and not particularly safe.

Who hasn’t entered a number incorrectly or simply misplaced information? And even if everything is correct, how can this information be used to make accurate, reliable decisions – decisions that are also independent of people?

Digitalization now offers the possibility of automating the collection of data on processes and machines, including by means of sensors, which provides a true picture of the business in real time. However, digitization does not just mean having electronic data, but also using it appropriately. Industry 4.0 opens the doors to another level equipped with artificial intelligence. Sophisticated software tools analyze data in real time and provide answers that either automatically lead to processes or help department heads and management make the best decisions for lean and thus cost- and energy-saving processes.

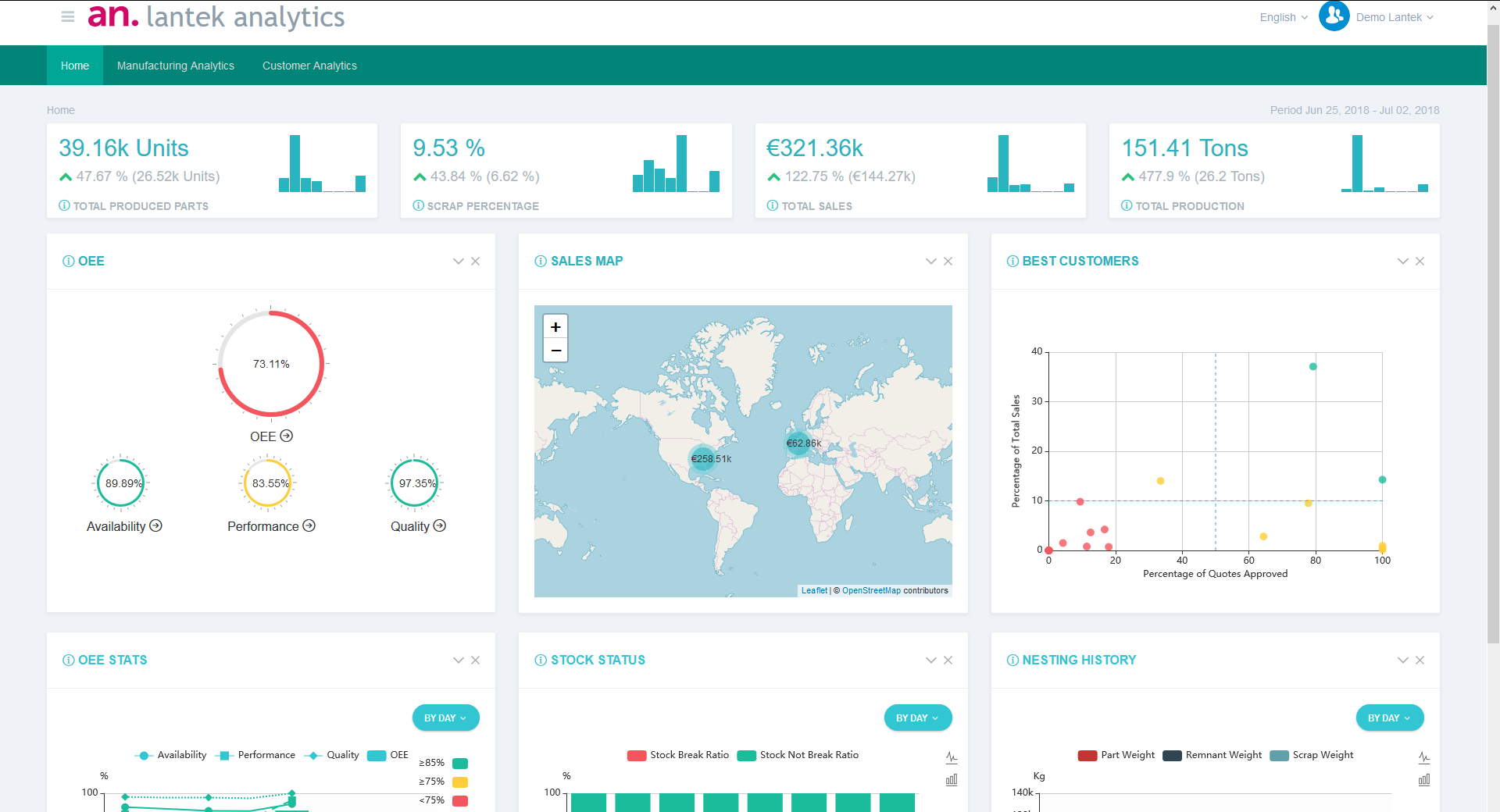

© Lantek

With Lantek Analytics, manufacturers in sheet metal production can identify inefficient operations and machines, as well as excessive material consumption, because the analysis tool provides them with data from their production process, from every machine and every operation. With this information, managers can determine the actual performance of each machine – or process such as tonnage of parts produced versus material processed and similar key data. This helps them make better decisions on how to fix problems and thus reduce overall costs for materials, energy and personnel.

Adapted to the needs of sheet metal manufacturing, Lantek Analytics analytics provides companies with everything they need. It has an intuitive and user-friendly dashboard with the metrics users need to make better decisions. The displays are supplied with historical data on a daily basis. Managers can select from hundreds of measurement data related to sheet metal cutting itself, machine tools, and all operational processes – and save hundreds of hours with the software tool compared to the effort that would be required with a generic business intelligence solution, for which custom metrics and data processes would have to be created.

At the same time, Lantek Analytics helps to identify trends by looking at historical data and, on this basis, to plan for the future in such a way that human, material and machine resources can be used optimally, according to the situation and thus as economically as possible. The tool consists of two modules – Manufacturing Analytics and Customer Analytics.

Above all, the optimization possibilities of manufacturing analytics support companies in saving energy and resources with the following options:

➢ OEE ratio: It can be used to evaluate and optimize the degree of utilization of the machine based on the following three parameters:

➢ Availability: Percentage of the programmed production time within the theoretical maximum operating time of the machine in which it actually produced.

➢ Output level: Actual production level of the machines compared to the theoretical maximum production level.

➢ Quality: Percentage of workpieces produced with perfect quality.

➢ Nestings: Percentage of workpieces, scrap metal and remnants generated during the cutting of nestings in production.

➢ Diverse filter options according to time period, location, type of machine, materials used, etc.

Customer analytics provides a better overall view of commercial processes and reveals potential for optimizing processes and thus increasing efficiency in relation to these aspects:

➢ Offers: Analysis by number of offers sent and accepted, conversion to order, value, and geographic location, among others.

➢ Sales: Among other things, meaningful analyses of invoices issued, costs, margins, and variances.

➢ Sales status: overview of the value of current, completed, delayed or disregarded orders as well as delivery deadlines.

Web:

www.lantek.com