In addition to the impending PFAS ban, stricter environmental regulations and energy prices are challenging the chemical industry. New pipelines for the use of hydrogen as an energy source and raw material are therefore becoming significantly more important. This is because they provide logistical support to chemical companies in meeting ecological requirements. With their quality pipes and piping systems for the realization of the pipelines, the manufacturers are proving to be reliable pillars for a successful future. So that the chemistry continues to be right.

The industry is changing: “Production processes in the chemical industry are currently undergoing rapid change,” explains the Fraunhofer Institute IGB. The chemical industry has to survive threatening scenarios, such as the EU Commission’s impending ban on perfluorinated and polyfluorinated alkyl substances (PFAS), which are criticized for their long-term stability and harmfulness to the environment. However, there are considerable reservations about a ban, including from the Federation of German Industries (BDI). “Broad regulation of entire substance groups, regardless of the actual risk of the individual substances, is not appropriate from the industry’s point of view.” The consequence of a ban would be considerable restrictions in the manufacture of plastic pipes and plastic-lined steel pipes.

Stainless steel

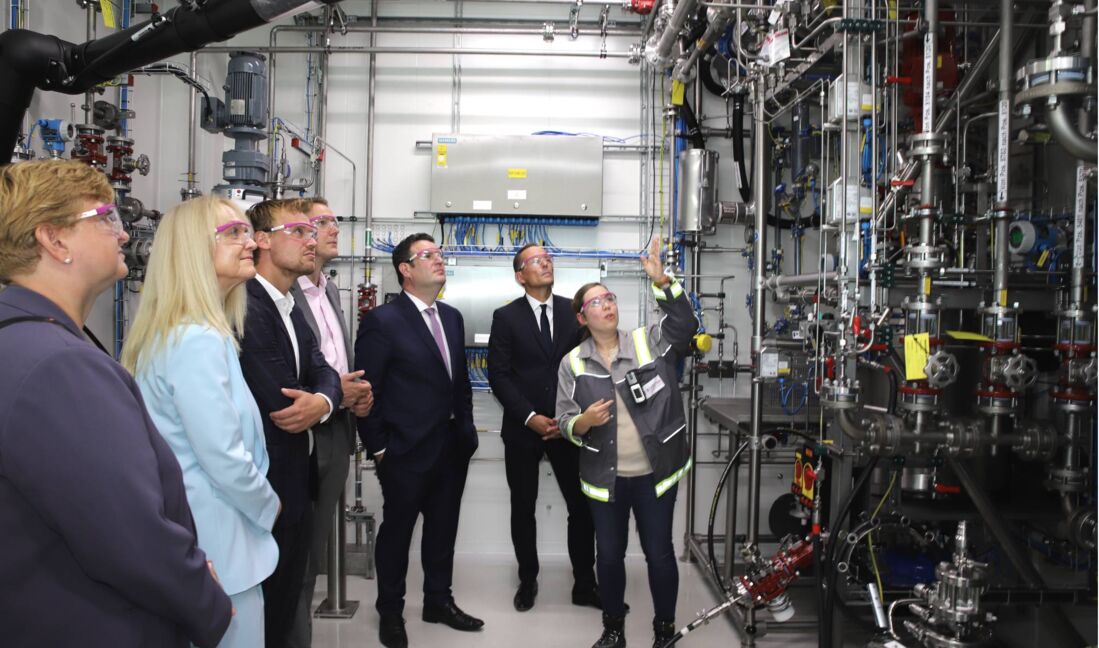

Evonik

Stainless steels are often used in the chemical industry. Outokumpu, for example, offers solutions that “reflect the industry’s requirements for performance in extreme temperatures, highly corrosive environments, high-pressure handling and high end-product purity”. The chemical industry without stainless steel tubes is unimaginable.

Bimetal pipes are also frequently used in chemical plants. They can consist of an outer tube made of stainless steel and an inner tube lining made of zirconium. Pipes made from these materials have one thing in common: they can withstand corrosive chemicals. Production losses and system and pipeline failures are avoided by using suitable materials. This is why “piping systems are essential for the safe transport of water, chemicals and gases,” emphasizes GF Piping Systems.

Hydrogen as a raw material and energy carrier

In order to maintain its competitiveness, the chemical industry urgently needs hydrogen – as a raw material, because it is the starting point for important chemical value chains, and also as an energy source. A suitable infrastructure is needed to transport this booming substance, which in turn requires numerous pipes. One advantage of using pipelines is that they are “the safest, most environmentally friendly and most reliable means of transportation”, explains the German Chemical Industry Association (VCI). This is why the chemical industry has long relied on pipelines.

In addition to the secure and environmentally friendly supply of chemical sites, a well-developed pipeline network is an important building block for the transformation of the industry towards greenhouse gas neutrality, according to the VCI. “They can be used to transport materials such as hydrogen, they can be used to temporarily store energy and they play an important role in the recycling of CO2 as part of carbon capture and storage (CCU/S) projects.” Pipelines “contribute to a secure and reliable supply of raw materials in times of insufficient rail freight transport capacities and seasonal transport restrictions on the waterways (low water levels on the Rhine),” explains the VCI.

Investments in pipelines

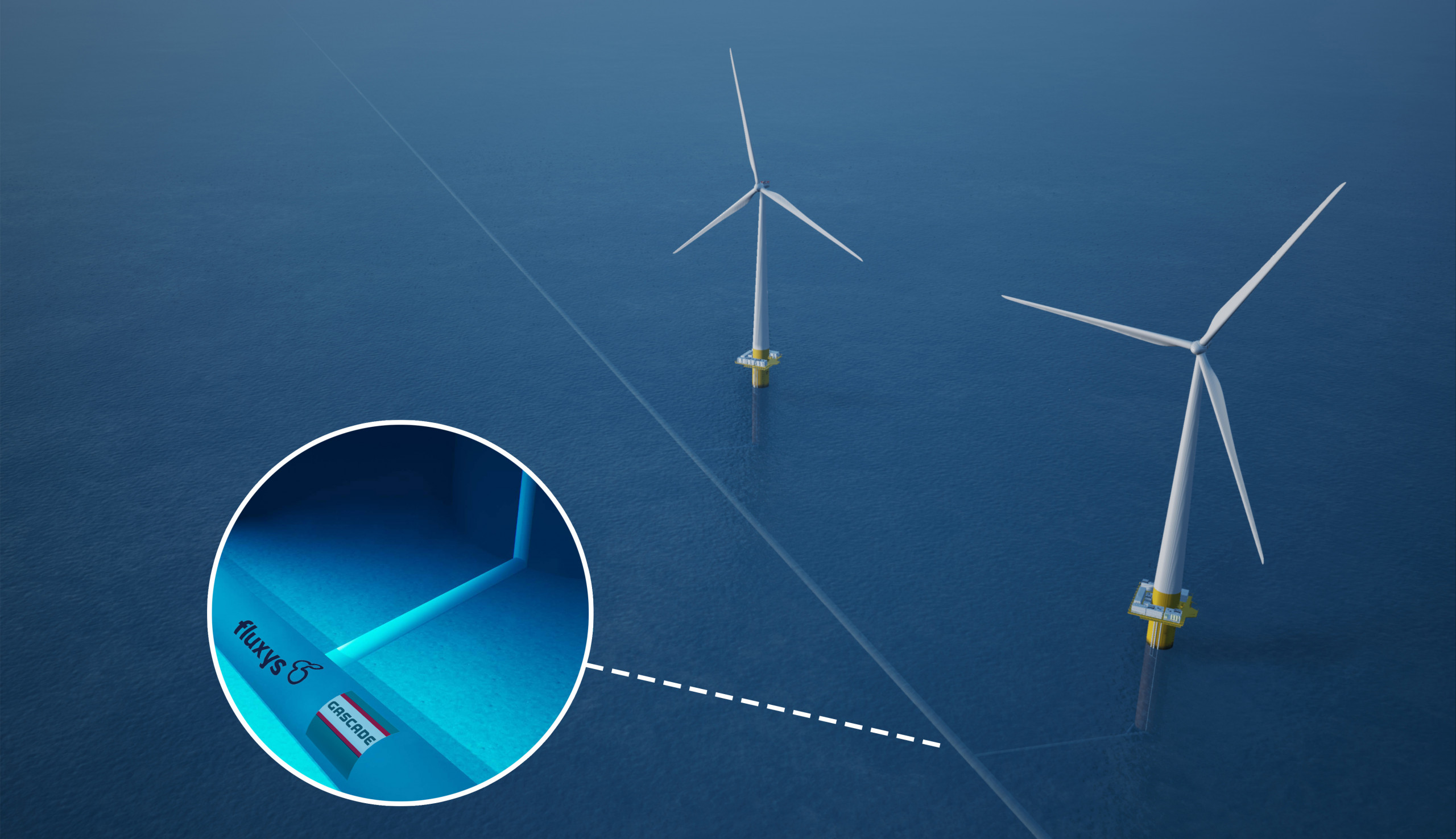

© Gascade

The chemical industry relies on pipeline networks. The continued construction of pipelines is an important task for the present and future of the chemical industry, for which pipe production is therefore essential. Ten companies – including BASF, Borealis, BP, Dow, Evonik and the Port of Rotterdam – have signed an agreement on cross-border pipeline development in the trilateral region. It is a cooperation for the chemical industry in Flanders, the Netherlands and North Rhine-Westphalia (“Trilog”), which has an annual turnover of 180 billion euros and employs more than 350,000 people. “Pipelines are the ‘lifelines’ of the trilateral chemical cluster; as the cleanest and safest mode of transport, their importance for the competitiveness of the industry will continue to grow,” emphasizes the German association VCI. Once again, numerous pipes are needed to build these pipelines.

A new 140-kilometer hydrogen pipeline will connect Germany and Denmark. From 2027, H2 is to flow from the island of Bornholm to Lubmin. “This cross-border hydrogen infrastructure is intended to drive the development of offshore wind energy in the region and throughout the Baltic Sea,” explains hydrogen network operator Gascade. It also shows a cost-efficient decarbonization path for the North-East European energy system. According to Gascade, in addition to the direct connection between Germany and Denmark, there are also plans to establish the interconnector with a future Baltic Sea backbone towards Sweden and Finland.

Pipes as an enabler of progress

With the increased use of hydrogen as an energy source, made possible by the underlying pipeline logistics, the chemical industry finds itself in a win-win situation, as it strengthens its international competitiveness against the backdrop of stricter environmental regulations and also in view of rising energy prices.

However, if renewable raw materials or biogenic residues are increasingly used as starting materials, “processes, plants, material formulations, process parameters or methods for quality control and safety assessment usually have to be adapted, which also has an impact on upstream and downstream industries,” explains the Fraunhofer IGB. Without the pipe industry, the change cannot be realized: it will become an enabler of progress in the chemical industry.

Petra Hartmann-Bresgen M.A., Messe Düsseldorf

Web:

messe-duesseldorf.de